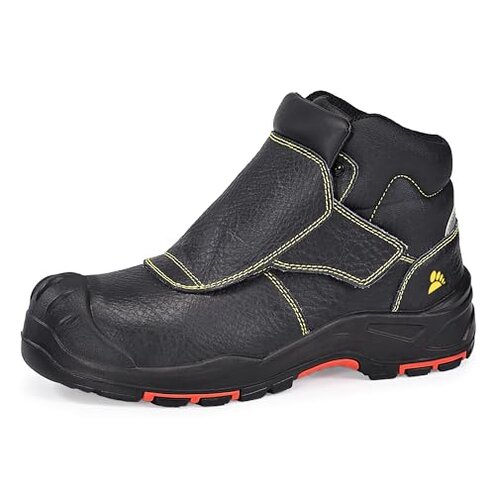

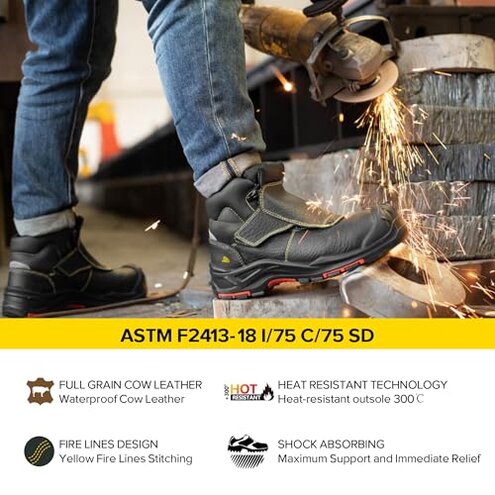

Product evaluated: SAFETOE Welding Boots for Men Composite Toe Safety Boots Fire Resistant Welding Boot 300℃Heat Resistant Welder Working Boots

Related Videos For You

How To Select The Best Work Boots For Welding

BOOTS & SHOES I WEAR AS A PIPELINE WELDER

Data basis Dozens of written reviews and several video demonstrations were reviewed between Jan 2024 and Jan 2026. Most feedback came from written reviews, supported by hands-on videos and buyer Q&A. The summary focuses on repeated buyer-visible patterns.

| Metric | SAFETOE boots | Typical mid-range boots |

|---|---|---|

| Comfort for long shifts | Inconsistent — comfort reports vary and break-in often needed. | Consistent — many mid-range boots offer predictable cushioning. |

| Fit accuracy | Unreliable — sizing frequently differs from label. | More reliable — standard sizing and clearer guidance. |

| Durability under use | Mixed — reports of early wear and seam/sole issues. | Stronger — mid-range alternatives often show longer sole life. |

| Heat resistance claim | Promised 300℃ but real-world performance has caveats. | Practical protection — mid-range often balances heat rating and real use. |

| Regret trigger | Sizing + durability — combined effect leads to replacement or refunds. | Fit or sole wear usually isolated and less likely to force early replacement. |

Will these boots fit like the size says?

Fit inconsistency Buyers commonly report that the boots do not match labeled sizes. This is a primary issue that appears at first try-on.

Why it matters The mismatch often forces returns, reorders, or extra time to exchange sizes. This is worse than the category baseline where one-size variation is expected but usually minor.

Do these boots fall apart under real work?

- Durability pattern Some buyers report seams, glue lines, or soles wearing earlier than expected, a secondary issue seen across written feedback.

- When it appears Problems often show after weeks to months of regular use, not always immediately after first wear.

- Worse-than-normal This feels more severe than typical mid-range boots, which usually last longer before similar failures.

- Work impact Early wear adds cost and downtime due to replacements or temporary fixes.

- Fix attempts Buyers commonly try sole glue or stitching repairs, which add time and expense.

Are they comfortable for all-day wear?

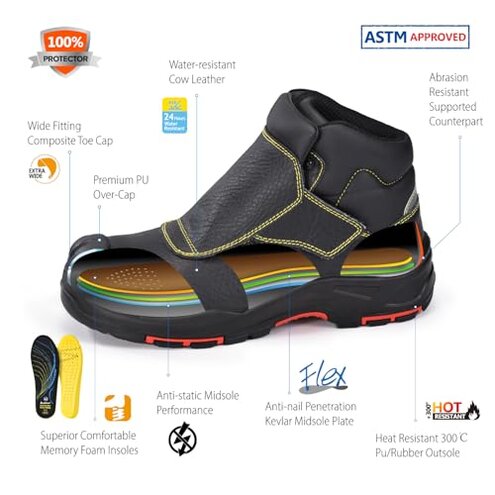

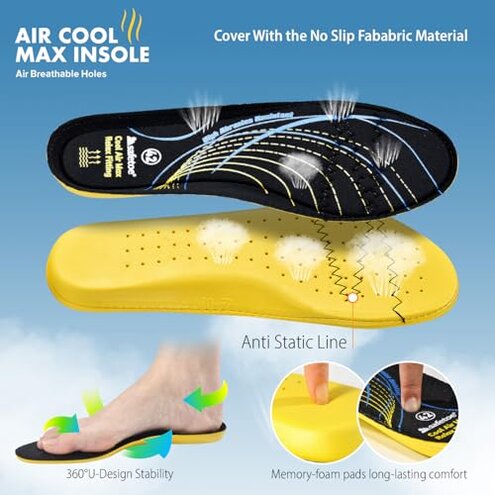

- Initial comfort Some users find the memory insole thin and report a notable break-in period, a primary pattern.

- Long shifts Comfort often worsens during long, standing shifts or hot days.

- Breathability Breathable mesh holes are reported but may not prevent sweat under heavy work.

- Sock dependency Comfort frequently depends on sock choice or adding aftermarket insoles.

- Weight perception Some buyers describe the boots as heavier than expected, which adds fatigue.

- Repair tradeoff Fixing comfort with new insoles reduces the perceived value for the original price.

- Expectation gap Many buyers expected immediate comfort similar to other mid-range work boots and were disappointed.

Do the heat-resistance claims hold up for welding work?

- Claim vs use The product advertises 300℃ resistance, but buyers note conditions matter and protection can be local, a secondary pattern.

- Real job context Performance varies when sparks repeatedly hit the same spot or during full-shift welding.

- Visible wear Spark stitching and fire-line details may resist small sparks but do not prevent all heat-related wear.

- Hidden requirement Buyers often must use additional spats or covers for heavy welding, which is an extra purchase and task.

- When it worsens Heat protection performance degrades with repeated exposure and abrasive contact.

- Category contrast Higher-end welding boots usually provide thicker, longer-lasting spark protection without add-ons.

- Safety impact Over-relying on the claimed rating without extra protection can increase risk during intensive welding.

- Cost tradeoff Adding spats or replacing boots sooner raises total ownership cost above the mid-range norm.

Illustrative excerpts

Illustrative: "Tight at first, then loose after a few wears — had to exchange size." — Primary

Illustrative: "Sole started separating after a month of shop work, had to glue it." — Secondary

Illustrative: "Good for small sparks but needed leg spats for heavy welding shifts." — Secondary

Illustrative: "Needed thicker socks and new insoles to stop foot pain on long days." — Primary

Who should avoid this

- Precision fit buyers Anyone who needs exact sizing or can't tolerate returns should avoid these boots due to inconsistent fit.

- Heavy-duty welders Workers doing continuous, heavy welding should avoid relying on the boots alone for spark protection.

- All-day comfort seekers Those needing immediate, all-day comfort without aftermarket insoles will be disappointed.

Who this is actually good for

- Light-duty weekend users Hobbyists or occasional grillers who accept adding spats for heavy sparks can tolerate the limitations.

- Budget-conscious buyers Shoppers willing to buy extra insoles or exchange sizes for a lower upfront price may find value.

- Non-critical fit needs Users who can try multiple sizes or accept a short break-in period can manage the fit variability.

Expectation vs reality

- Expectation (reasonable) Buyers expect a labeled size to match their usual work-boot size.

- Reality Sizing often varies and may require exchanges, adding time and shipping effort.

- Expectation (reasonable) Heat-resistance labels imply protection for typical welding sparks.

- Reality Protection can be local and may need extra spats or covers during heavy-duty welding.

Safer alternatives

- Choose trusted sizing guides Look for sellers offering detailed size charts and free returns to reduce fit risk.

- Prioritize reinforced soles Pick boots with documented longer sole warranties to avoid early wear.

- Buy with spats If welding heavily, buy boots that either include or recommend leg spats to avoid hidden purchases later.

- Test comfort early Try boots on short shifts first and plan for replacement insoles if cushioning is thin.

The bottom line

Main regret trigger The combination of inconsistent fit and mixed durability makes this product riskier than typical mid-range work boots.

Why it matters These issues appear early in ownership and often force returns, repairs, or extra purchases.

Verdict Avoid if you need dependable sizing, long-term durability, or heavy-duty welding protection without add-ons.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.