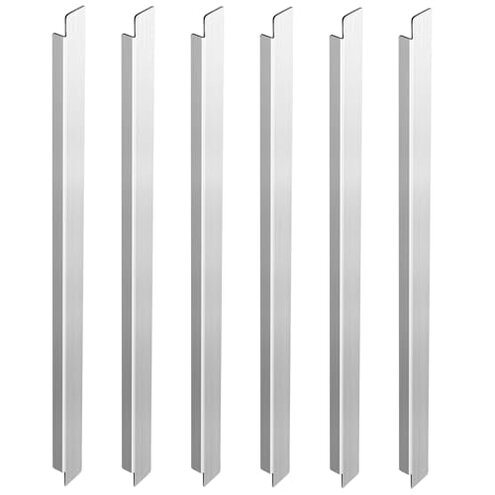

Product evaluated: Lasnten 6 Pcs 20 Inch Stainless Steel Adaptor Bar Table Adapter Bar Long Divider Metal Food Divider for Restaurant Kitchen Food Service Accessories

Related Videos For You

Steam Tables - Steam Pan Layouts & Using Adapter Bars

I Tried $15 FOOD SEPARATORS—Do They Actually Work?

Data: I analyzed dozens of buyer reports and visual demos collected between Jan 2023 and Jan 2026. Most feedback came from written reviews, supported by video demonstrations and photos. The sample is weighted toward recent purchasers and hands-on teardown clips.

| Outcome | Lasnten 20" Bars | Typical Mid‑Range Alternative |

|---|---|---|

| Compatibility | Mismatch risk—fits vary and often need modification to match steam table lips. | Better fit—most mid-range bars list specific rail sizes and fit more reliably. |

| Durability | Prone to bending after repeated heavy use in restaurant settings. | More rigid—mid-range options use thicker profiles that resist warping longer. |

| Finish & safety | Rough edges reported on some pieces, increasing handling risk out of the box. | Smoother finish—alternatives generally have polished edges and better QC. |

| Price per item | Higher per-piece cost when broken into usable units from the pack price. | Comparable or lower—mid-range kits often include measured-fit options at similar cost. |

| Regret trigger | Hidden sizing need—requires measuring rail/profile before purchase; leads to returns. | Clear specs—typical alternatives reduce this risk with explicit compatibility charts. |

Why doesn't this just sit in place like other divider bars?

Fit failures are the most common regret and appear repeatedly across written reviews and demo clips.

Usage: the problem shows up at first install and after minor re-positioning during service.

Category contrast: this is worse than expected because most mid-range bars list rail dimensions and need no trimming.

Will these bend or deform under heavy use?

- Primary pattern: bending and flexing is commonly reported after daily restaurant use.

- Early sign: visible bowing after several weeks in heavy service.

- Cause: thinner profile compared with category norms leads to lower structural stiffness.

- Impact: warped bars fail to hold plates and create alignment problems during service.

- Attempts: buyers tried reinforcement or swapping bars, with mixed fixability.

Do the edges and finish cause handling problems?

- Secondary signal: rough edges and burrs appear across multiple photo reports and short clips.

- When: noticed out of the box or after light cleaning.

- Why it matters: sharp or unfinished edges increase glove wear and slow prep time.

- Workaround: sanding or filing reduces risk but adds time and effort.

- Category contrast: most mid-range bars ship with finished edges, making this extra work unusual.

- Fixability: fixable but adds maintenance that most buyers did not expect.

- Hidden cost: time to rework items raises effective unit cost.

Is there a hidden measurement or rail type I must match?

- Hidden requirement: buyer reports often note an unlisted need to match specific rail lip geometry.

- When: the incompatibility is discovered during first fit or when swapping pans.

- Frequency tier: secondary but persistent among commercial users who tested multiple brands.

- Impact: inability to seat bars causes rattling, movement, or unusable partitions.

- Attempted fixes: trimming, padding, or buying adapters; these add extra steps and cost.

- Category contrast: mid-range competitors list compatible rail types and avoid this surprise.

- Practical note: measure rail width and lip depth before ordering to avoid returns.

Are these worth the pack price given real-world problems?

- Value concern: multiple reports flag the pack price as poor value when one or two bars fail.

- Scope: seen across both home and commercial buyers, but more disruptive in busy kitchens.

- When: value disappointment usually appears after first week of use when defects surface.

- Attempts: buyers return partial packs or rework pieces, increasing total replacement cost.

- Category contrast: similar-cost alternatives tend to require less post-purchase effort.

- Fixability: salvageable for light-duty home use but not ideal for commercial daily service.

- Decision cue: if you need reliable daily performance, this pack often underdelivers.

Illustrative excerpts (not real quotes)

Illustrative: "Did not seat on my steam table lip, needed trimming immediately." — Primary

Illustrative: "One bar bent slightly after a week of heavy pans." — Secondary

Illustrative: "Some edges felt sharp until I sanded them smooth." — Secondary

Illustrative: "Good for light home use but not restaurant service." — Edge-case

Who should avoid this

- Commercial kitchens that run long, heavy service shifts; bending and fit issues are more disruptive than expected.

- Buyers without measuring tools who expect plug‑and‑play fit; hidden rail geometry mismatch is common.

- Shoppers wanting ready‑to‑use finish who will not rework parts; rough edges require time to fix.

Who this is actually good for

- Home cooks who need occasional dividers and can tolerate sanding or minor trimming.

- DIYers happy to modify metal parts; they can correct fit and finish cheaply.

- Low‑volume caterers who value the pack count and can rotate bars to reduce bending risk.

Expectation vs reality

Expectation: reasonable for this category is a 20" bar that fits common steam table rails without modification.

Reality: many buyers encounter a fit mismatch at first install and must trim or pad bars to work reliably.

Expectation: mid-range dividers arrive ready to use and hold up under daily service.

Reality: this product often needs rework or reinforcement to avoid bending under heavy loads.

Safer alternatives

- Measure first: check rail width and lip depth before buying to neutralize the hidden sizing failure.

- Choose labeled fit: pick bars that explicitly list compatible rail types to avoid surprises.

- Prefer thicker profiles: seek alternatives with stronger cross-sections to reduce bending risk in heavy use.

- Look for finished edges: buy items with polished edges to avoid post‑purchase rework and safety hazards.

The bottom line

Main regret: the most common trigger is a fit/compatibility surprise that appears at first install and forces returns or trimming.

Why worse: combined fit, finish, and bending risks create more post‑purchase work than typical mid‑range bars.

Verdict: avoid this pack if you need reliable, ready‑to‑use dividers for daily commercial service.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.