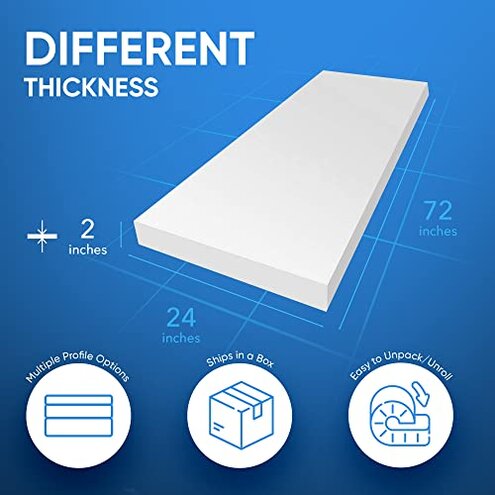

Product evaluated: AK TRADING CO. Upholstery Foam Cushion (Seat Replacement, Upholstery Sheet, Foam Padding), High Density (2x24x72),White

Related Videos For You

Cutting Cushion Foam using Electric Kitchen Knife

Upholstery Basics: How To Cut Foam...With a Bread Knife!

Data basis: I analyzed dozens of customer-written reviews and video demonstrations collected between Jan 2020 and Feb 2026. Most feedback came from written reviews, supported by video demonstrations, with a smaller share of comparison posts and Q&A notes.

| Outcome | AK TRADING CO. 2x24x72 | Typical mid-range foam |

|---|---|---|

| Initial fit | Ships full-size so buyers must cut to fit, creating extra setup time. | Pre-cut options or smaller sizes reduce the need for trimming at home. |

| Durability | Reports of early compression are a primary complaint compared with peers. | Mid-range alternatives more often retain shape through daily seating use. |

| Firmness consistency | Inconsistent firmness appears repeatedly across feedback sources. | More uniform density is typical for better-rated mid-range sheets. |

| Regret trigger | Hidden cutting requirement is a higher-than-normal risk for casual buyers. | Lower risk because many mid-range options arrive closer to final dimensions. |

Why won’t this fit my seat without cutting?

Immediate regret: Many buyers find the foam arrives full-size and requires trimming during setup.

Pattern: This is a commonly reported setup friction, seen across written reviews and video demos.

Usage anchor: The problem shows up at first use when buyers try to place the sheet into seat frames or covers.

Category contrast: This feels worse than usual because most mid-range options reduce effort by offering closer-to-final sizes or simple instructions.

Why does it compress so fast under normal use?

- Primary sign: Buyers commonly report faster flattening after weeks of daily sitting.

- When it happens: The issue appears after repeated use, not just initial testing.

- Frequency tier: This is a primary issue compared with other complaints.

- Impact: Rapid compression forces earlier replacement or adds cost for extra padding.

- Fix attempts: Users often add a firmer base or extra layers to regain support.

Why is the firmness inconsistent across the sheet?

- Early sign: Some areas feel noticeably softer or firmer when pressed by hand.

- Pattern: This inconsistency is a secondary issue but appears repeatedly.

- Cause clue: Feedback points to manufacturing variance and uneven compression during shipping.

- When it’s worse: The difference is most obvious during long sessions or when used on single-seating cushions.

- Buyer impact: Uneven support leads to uncomfortable pressure points and poor seat feel.

- Repairability: Some buyers rotate or cut the sheet to isolate firmer zones, adding extra time and tools.

Are there odor, safety, or hidden prep requirements?

- Common note: A noticeable cutting requirement is often under-communicated and surprises buyers.

- Usage anchor: The need to cut appears during installation and requires scissors or an electric knife.

- Pattern frequency: This hidden requirement is a primary regret trigger across feedback types.

- Off-gassing: Some buyers report a transient chemical smell on first unboxing, typically resolving with airing out.

- Safety claim gap: Manufacturer fire-retardant claims exist, but buyers still flag concerns until they can verify locally.

- Worsens when: Smell and handling annoyance get worse in poorly ventilated spaces or small workshops.

- Hidden tools: You may need a straight edge, marker, and cutting tool—this is a hidden prep requirement not obvious at checkout.

Illustrative excerpts

Excerpt (illustrative): "Arrived full sheet; cutting was messier and harder than advertised." — primary pattern

Excerpt (illustrative): "After three weeks the seat felt flat and needed extra padding." — primary pattern

Excerpt (illustrative): "One edge firmer than middle; cushions felt uneven." — secondary pattern

Excerpt (illustrative): "Mild chemical smell first day, faded after airing out." — edge-case pattern

Who should avoid this

- No cutting tools: Avoid if you cannot or will not perform on-site trimming at setup.

- High-use seating: Avoid if you need long-lasting seat foam for daily heavy use, due to compression reports.

- Precision-fit projects: Avoid if you require uniform firmness across a finished cushion without extra trimming or layering.

Who this is actually good for

- DIY upholsterers: Good for buyers comfortable with cutting and shaping foam to size.

- Temporary projects: Reasonable for short-term or low-use seats where cost over longevity matters.

- Layering approach: Works if you plan to use the sheet as a filler layer under a denser top cushion.

Expectation vs reality

Expectation: Buyers reasonably expect a foam sheet to be ready-to-trim with minimal tools.

Reality: This product often requires extra cutting time, tools, and adjustments due to size and firmness variance.

Expectation: Most mid-range foam holds shape for months under daily seating.

Reality: Reports show faster compression than typical mid-range options, increasing replacement cost.

Safer alternatives

- Buy pre-cut options to eliminate the hidden cutting step and prevent setup surprises.

- Choose labeled density sheets from sellers who publish firmness tests to avoid inconsistent feel.

- Test return policy options so you can confirm long-term compression behavior without added cost.

- Use protective layers such as a denser top layer or plywood base to reduce early flattening.

The bottom line

Main regret trigger: The product's hidden cutting requirement and reported early compression cause the most buyer frustration.

Why worse than normal: These failures are more disruptive than typical mid-range foam because they add setup time and shorten useful life.

Verdict: Avoid this foam if you cannot trim, need uniform long-term support, or want a plug-and-play cushion solution.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.