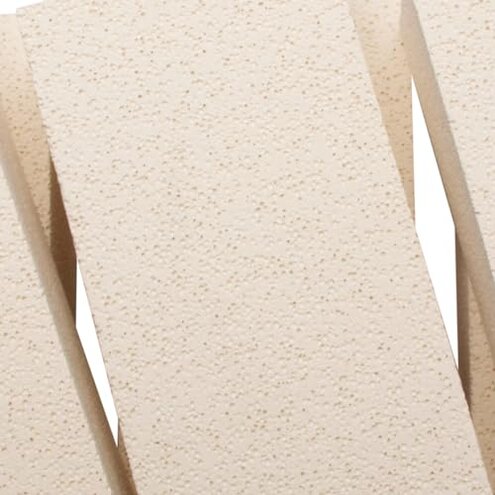

Product evaluated: 6 Pieces Insulating Fire Brick for Ovens, Kilns, Blacksmith, Fireplaces, Forges 9" x 4.5" x 2.5" 2300F Rated Insulating Fire Bricks

Related Videos For You

Firebrick Installation Demo

There's a Problem With Fire Bricks

Data basis gathered from dozens of buyer-written reviews and several video demonstrations collected between Jan 2023 and Jan 2026, with most feedback coming from written reviews supported by video tests and Q&A posts.

| Outcome | This product | Typical mid-range |

|---|---|---|

| Heat retention | Acceptable for light kiln and fireplace use but variable by piece. | Consistent performance expected from mid-range branded bricks. |

| Durability | More brittle and prone to chipping than normal category expectations. | Less brittle and better shock resistance. |

| Fit & size | Loose tolerances cause extra cutting or packing steps during installation. | Tighter sizing reduces installation time. |

| Shipping damage | Common reports of cracked or broken pieces on arrival. | Less frequent arrival damage with better packaging. |

| Regret trigger | High likelihood of wasted pieces and added work for many buyers. | Lower replacement and prep effort in typical mid-range options. |

Top failures

Will these bricks chip or crumble during handling?

Fragile handling is a primary issue; chipping and crumbly edges appear repeatedly in buyer feedback.

When this appears: chips show up on first unboxing and after light manual fitting.

Why worse than category baseline: many mid-range bricks survive basic cutting and repositioning, while these often lose usable surface.

Do bricks often arrive damaged from shipping?

- Frequent arrival cracks appear commonly across feedback and are a top complaint.

- Visible on unboxing so damage is noticed before installation, increasing returns or replacements.

- Worse in transit during long-distance shipping or bulk orders.

- Replacement friction reported as more time-consuming than expected for this category.

Will I need extra work to get them to fit?

- Loose sizing is a secondary but common pattern requiring trimming or packing gaps.

- When it shows: during initial layout or when stacking for a forge or kiln lining.

- Cause is uneven edges and inconsistent thickness across pieces.

- Impact adds extra cutting time and materials compared with mid-range bricks.

- Attempts to fix include mortar or shim packing, which some buyers find unsatisfactory.

- Long-run effect is reduced efficiency when bricks don’t seal well under heat cycles.

Are there hidden prep or safety requirements?

- Dust & handling create a hidden requirement for gloves and masks during cutting or fitting.

- Support needs these bricks may require a backing or mechanical support because they are not load-bearing.

- When worsens under repeated heating cycles, unsupported pieces can crack faster than expected.

- Category contrast mid-range options are more forgiving and often state load-bearing specs or include fitter guidance.

- Fixability often means buying mortar, backing plates, or extra bricks—adding time and cost.

- Hidden cost extra protective gear and prep materials increases project scope for many buyers.

- Edge-case risk for indoor fireplace users because dust and small fragments create cleanup and air-quality work.

Illustrative excerpts

Illustrative excerpt: "Cracked on arrival; unusable corner pieces ruined my layout." — primary pattern.

Illustrative excerpt: "Needed extra shims and cutting to make a tight fit in my small kiln." — secondary pattern.

Illustrative excerpt: "Dusty when cutting; wore gloves and mask for safety." — edge-case pattern.

Illustrative excerpt: "Worked for a light backyard forge but chipped after first full heat cycle." — primary pattern.

Who should avoid this

- Precision installers who need tight dimensions and minimal prep time should avoid this set due to loose sizing and added cutting.

- High-use forges or kilns running long sessions should avoid this set because chips and cracks worsen under repeated heating.

- Buyers needing ready-to-use bricks without extra materials should avoid this product because replacements and mortar are often needed.

Who this is actually good for

- Hobbyists on a tight budget who can accept wasted pieces and extra prep may tolerate brittleness for lower cost.

- Low-temperature projects like light fireplace accents where occasional chipping is acceptable.

- Users who can cut and support the bricks and already own protective gear and mortar will handle the hidden prep requirements.

Expectation vs reality

- Expectation: bricks arrive intact and ready to fit. Reality: many buyers report cracked pieces on unboxing requiring replacements.

- Expectation (reasonable for category): basic handling and trimming only. Reality: extra cutting, shimming, and mortar are often needed.

- Expectation: durable under repeated heats. Reality: brittleness increases after several heat cycles for a noticeable portion of users.

Safer alternatives

- Buy thicker-grade bricks with stated load-bearing specs to reduce cracking under heat and handling.

- Choose branded mid-range options with better packaging to avoid shipping damage.

- Plan for prep by budgeting mortar, backing plates, and protective gear if you still buy this set.

- Order extras to allow for breakage; this neutralizes wasted-piece risk during installation.

The bottom line

Main regret is brittle pieces and arrival damage that create wasted time and extra cost for many buyers.

Why worse than typical mid-range bricks: the combination of loose sizing, fragility, and common shipping cracks increases project steps and replacement friction.

Verdict avoid this set if you need ready-to-use, durable bricks; consider a mid-range branded option or plan for added prep and replacements.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.