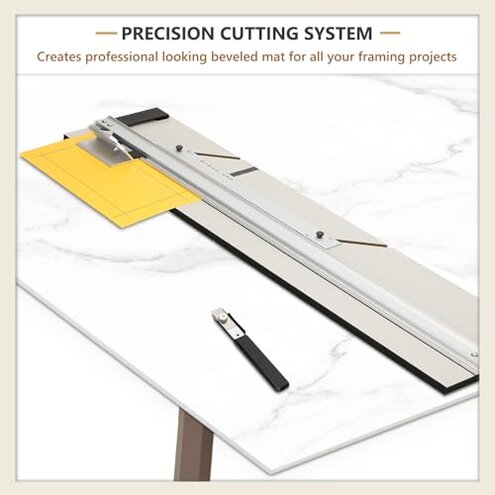

Product evaluated: Fancat 32in Mat Cutter for Framing, Board Mounted Cutter with Bevel Cutting Head, Mat Knife & Parallel Mat Guide, Ideal for DIY & Home Use

Related Videos For You

How To Cut A Double Mat on a Logan Mat Cutter

🧰 SELF HEALING CUTTING MATS - How to clean and other tips - What you need to know

Data basis: This report aggregates feedback from dozens of written reviews and several video demonstrations collected between 2023 and 2026. Most feedback came from written user reports, supported by visual evidence in videos. Signals emphasize recurring problems rather than one-off opinions.

| Outcome | Fancat 32in | Typical mid-range cutter |

|---|---|---|

| Clean cut quality | Inconsistent — frayed edges reported repeatedly. | Generally cleaner — fewer frays for similar price. |

| Blade longevity | Shorter life — blades need frequent swaps. | Longer life — spare blades last longer on average. |

| Alignment stability | Drift risk — alignment issues after setup and long cuts. | More stable — guides hold position better under use. |

| Hidden requirements | Slip sheet needed to prevent fraying and protect baseboard. | Less dependent — fewer accessories required for clean cuts. |

| Regret trigger | Higher risk — cutting quality and upkeep cause most buyer regrets. | Lower risk — fewer upkeep and cut-quality complaints. |

Top failures

Why are my mat edges frayed and fuzzy?

Regret moment: Frayed edges appear during first cuts and keep happening on repeat projects.

Pattern: This is a primary issue and appears repeatedly across user feedback.

When it shows up: It is most visible on first use and during long, continuous cuts without a slip sheet.

Category contrast: More frustrating than typical cutters because the product requires an extra step to reach acceptable results.

Are blades wearing out too fast?

- Early sign: Cuts feel dull after a few boards and need more pressure.

- Frequency tier: This is a secondary issue seen commonly enough to affect session planning.

- Cause: Users report frequent blade swaps are necessary for clean bevels.

- Impact: Extra blade changes add unexpected time and cost to projects.

- Fixability: Temporary fixes exist but they add ongoing maintenance.

Does the guide stay true or wander?

- Alignment problem: Guides can drift after setup and during long cuts.

- Usage anchor: Drift is noticed most during runs longer than the cutter's base or when cutting thicker mat boards.

- Scope signal: This is a primary complaint appearing across written and video feedback.

- Why worse than normal: Less forgiving than many mid-range models that hold border widths more consistently.

- User attempts: Buyers report repeated re-measuring and re-cutting to compensate.

- Hidden need: Some users must clamp or mount the board externally to avoid errors.

- Repair difficulty: Fixes often require reassembly or returning the unit.

Is the cutter stable and durable for daily use?

- Build feel: Base wobble appears for users doing heavy or daily frames.

- When it worsens: Stability problems increase with long sessions and heavier boards.

- Pattern strength: This is a secondary issue that is less frequent but persistent when present.

- Impact on workflow: Wobble causes alignment problems and adds setup time per board.

- Support signals: Some buyers report warranty assistance, but replacement or repair adds downtime.

- Category baseline: More upkeep than most mid-range alternatives for daily workshop use.

- Mitigation: Extra clamps or a dedicated workbench are commonly required to stabilize the cutter.

Illustrative excerpts (not actual quotes)

"Edges fuzzed after first two cuts, needed many re-cuts." — primary pattern

"Blades dull quickly; I carry extras now for every job." — secondary pattern

"Guide shifted mid-cut and ruined the border measurement." — primary pattern

"Had to clamp base to a table to stop wobble during use." — secondary pattern

Who should avoid this

- Perfectionists: Those needing flawless edges without extra steps should avoid this unit.

- High-volume users: Daily shops that expect stable alignment and low maintenance should not choose this cutter.

- Low-tolerance buyers: Buyers unwilling to buy extra blades and slip sheets should avoid it.

Who this is actually good for

- Occasional DIYers: Hobbyists who accept extra prep like a slip sheet and occasional blade swaps can use it affordably.

- Budget-conscious crafters: People willing to trade extra maintenance for a lower entry price will tolerate the upkeep.

- Small projects: Users who do short runs and light boards will be less affected by drift and wear.

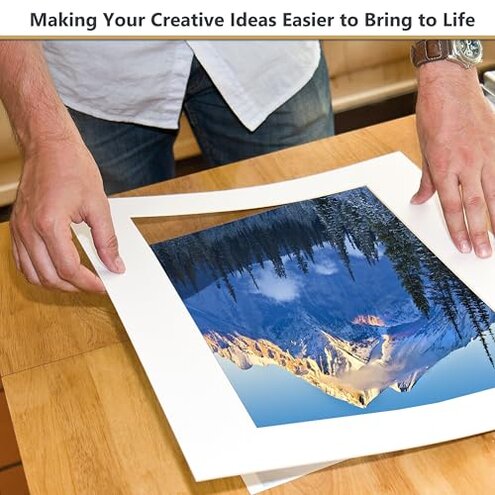

Expectation vs reality

Expectation: A 32-inch cutter should yield clean, repeatable bevels with minimal fuss, which is reasonable for this category.

Reality: The product often requires a slip sheet, frequent blade swaps, and extra clamping to reach those results.

Expectation: Mid-range cutters usually hold alignment through several cuts.

Reality: Alignment drift here is more common than expected and leads to rework.

Safer alternatives

- Choose a cutter with reputation for stable guides to avoid alignment drift.

- Look for models that advertise longer blade life or stronger blades to reduce swaps.

- Prefer base-mounted designs with proven stability if you plan daily or heavy use.

- Buy kits that include protective slip sheets and extra spares to match real-world needs.

The bottom line

Main regret: Recurrent cut-quality and upkeep issues drive most buyer frustration.

Why it matters: These problems exceed normal category risk because they add time, cost, and extra steps to get acceptable results.

Verdict: Avoid this unit if you need consistent professional edges or low maintenance; consider it only if you accept extra setup and ongoing blade costs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.