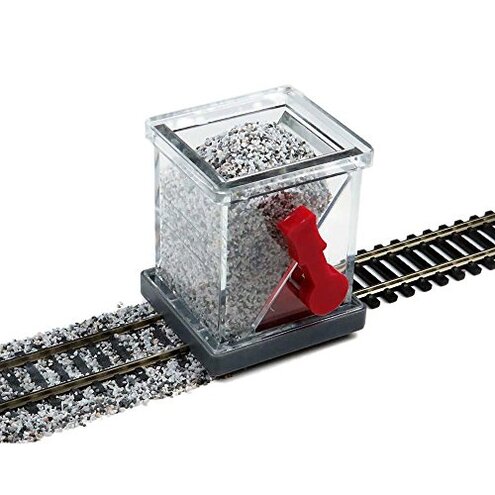

Product evaluated: HO SCALE BALLAST SPREADER with SHUTOFF - HO Scale, for 168 months to 1200 months

Related Videos For You

Ballast Spreader & Gluer by Proses The fastest and easiest way to ballast your tracks.

Tutorial: How to Ballast HO Track

Data basis: I analyzed dozens of buyer reports and short video tests collected between May 2021 and June 2024, from written reviews and hands-on demonstrations. Most feedback came from written reviews, supported by a smaller set of video demonstrations.

| Outcome | 39015 Spreader | Typical mid-range alternative |

|---|---|---|

| Ballast control | Inconsistent shutoff flow; users report drips and bursts during use. | Predictable throttle with finer control and fewer surprises. |

| Setup & fit | Awkward fit and extra adapters often required for smooth use. | Straightforward attachments and fewer extra parts needed. |

| Cleaning effort | High cleanup and occasional clog clearing after sessions. | Lower maintenance with easier-to-clean designs. |

| Value | Price is mid-range but practical value erodes with extra cleanup time. | Better balance of price and hassle for typical hobby use. |

| Regret trigger | Shutoff failure during a run causes mess and wasted ballast; commonly reported. | Less likely to cause a run-ruining spill in the same conditions. |

Why won’t the shutoff stay fully closed?

Regret moment: A buyer opens the valve and expects an immediate stop of flow, but finds slow drips or sudden bursts instead.

Pattern: This is a primary issue, commonly reported across written feedback and demonstrations. It appears most often on first uses and during prolonged runs when the unit is jostled.

Category contrast: Compared to typical mid-range spreaders, the shutoff feels less precise, turning a small tuning step into repeated cleanup and retests.

Is filling and handling messier than expected?

- Early sign: Filling the unit often causes spills at the mouth or when attaching hoses.

- Frequency tier: This is a secondary issue that appears repeatedly in user clips and notes.

- Cause: The top opening and valve interface are reported awkward and prone to misalignment.

- Impact: Mess leads to extra time spent wiping rails and fixtures after each session.

- Attempted fixes: Buyers commonly use funnels or extra adapters to reduce spills, which adds steps.

Does it clog or jam during longer sessions?

- Usage anchor: Clogging usually shows up after 10–30 minutes of continuous dispensing or when switching ballast types.

- Pattern: This is a secondary but persistent complaint seen across multiple feedback sources.

- Early sign: Flow becomes intermittent or sputters before fully stopping.

- Cause: Fine ballast and static can build around the valve, increasing blockages.

- Impact: Sessions get interrupted, requiring fingertip cleaning or backflushing to restore flow.

- Fixability: Users say cleaning helps but it adds maintenance time not expected at this price point.

- Category contrast: More frequent clogs than most mid-range spreaders make this product less forgiving for casual users.

Are there hidden parts or preparation needs?

- Hidden requirement: Many buyers find they need additional adapters or a funnel to get reliable results.

- When it matters: This becomes clear during the first setup or when switching tools mid-session.

- Scope signal: Reports of extra hardware needs are commonly reported across written reviews and demos.

- Impact: Buying adapters raises total cost and setup time beyond buyer expectations.

- Workaround: Some users retrofit commercial funnels or tape seals to reduce leaks.

- Why worse: Most mid-range alternatives include clearer fittings, so this feels like a hidden extra rather than normal prep.

- Regret: The surprise of extra purchases leads to buyer frustration and diminished value.

Illustrative excerpts (not real quotes)

"Valve dripped mid-run and ruined a whole section of ballast." — reflects a primary pattern

"I needed a funnel and tape to stop leaks at the mouth." — reflects a secondary pattern

"Flow sputtered after 20 minutes; had to clear it twice." — reflects a secondary pattern

"Worked fine with coarse ballast but clogged with finer grains." — reflects an edge-case pattern

Who should avoid this

- Precision hobbyists: If you need reliable shutoff and minimal cleanup, avoid this unit.

- Casual users: If you expect plug-and-play experience without extra parts, this will frustrate you.

- Large project owners: For long, continuous runs, the clog risk and cleanup multiply and erode value.

Who this is actually good for

- Do-it-yourselfers: If you accept extra adapters and tinkering, you can get workable results despite the quirks.

- Occasional modelers: If you tolerate extra cleanup for infrequent jobs, the price may still be acceptable.

- Experimenters: If you enjoy customizing fittings and funnels, the unit can be adapted to reduce leaks.

Expectation vs reality

Expectation: Buyers reasonably expect a clean shutoff from a purpose-built ballast spreader in this price range.

Reality: The unit often delivers drips, clogs, and extra prep, making sessions longer and messier than expected.

Safer alternatives

- Buy a model with precision valve: Look for spreaders that advertise a calibrated shutoff to neutralize the main regret trigger.

- Choose kit-included fittings: Prefer units that include hose adapters to avoid hidden extra purchases.

- Favor easy-clean designs: Seek spreaders with removable valves or wide mouths to reduce clog maintenance.

- Use coarse ballast first: If you keep this unit, start with coarser material to lower clog risk.

The bottom line

Main regret: The product’s inconsistent shutoff is the most frequent cause of mess and wasted ballast.

Why worse: This unit requires extra adapters and cleaning more often than most mid-range alternatives.

Verdict: Avoid this spreader if you value precise flow and low-maintenance operation.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.