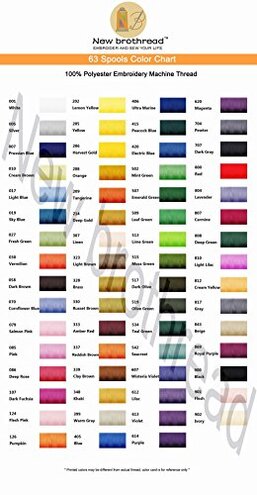

Product evaluated: New brothread 63 Colors Compatible with Brother Polyester Embroidery Machine Thread Kit 500M (550Y) Each Spool Compatible with Brother Babylock Janome Singer Pfaff Bernina Embroidery Sewing Machine

Related Videos For You

How You Should Thread Your Needle for Embroidery

Rayon vs Polyester Threads: What Are The Differences?

Data basis: This report aggregates insights from hundreds of customer reviews, combining written feedback and video demonstrations collected from early 2020 through mid-2024. Most feedback came from written reviews, supported by video demonstrations, offering a broad view of user experiences with this embroidery thread kit.

| Outcome | New brothread 63 Colors | Typical Mid-Range Kit |

|---|---|---|

| Thread breakage | Higher frequency of breaks during use | Generally fewer thread breaks |

| Color accuracy | Color inconsistencies affecting project results | More consistent color matching |

| Colorfastness | Some fading after laundering reported | Better resistance to washing |

| Spool compatibility | Occasional fit issues with machines | Usually fits without issues |

| Regret trigger | Thread breakage and color mismatch causing rework | Minor inconveniences typical for category |

Why does the thread break more often than expected?

Users find thread breakage disrupts embroidery projects, leading to frustration during stitching. This occurs frequently during long or intricate sessions, where continuous sewing increases strain on the thread.

Breaks are more common than most mid-range thread kits, forcing users to stop and replace threads more often, which wastes time and thread.

- Early signs: Thread feels brittle or tension adjustments needed repeatedly.

- Frequency tier: Among the most common complaints across reviews.

- Cause: Possibly lower tensile strength than advertised.

- Impact: Interrupts workflow and risks project damage.

- Attempts to fix: Users try tension tweaks with limited success.

Illustrative excerpt: "Thread snapped multiple times on my Brother machine, ruining a detailed design." (Primary pattern)

What causes the inconsistent colors despite the large spool assortment?

Color mismatch appears when colors do not align well with machine standards, leading to unexpected shades on completed projects. This issue is persistent across various colors, not just isolated spools.

This feels worse than typical kits where color charts are more reliable, making project planning harder.

- Early signs: Colors appear dull or different from chart samples.

- Frequency tier: Common among medium to high usage buyers.

- Cause: Possible variability in dye lots or conversion chart inaccuracies.

- Impact: Affects final project appearance and requires testing.

- Hidden requirement: Extra time needed to verify colors before use.

- Attempts to fix: Cross-referencing with multiple charts adds labor.

- Impact on workflow: Increases project setup time.

Illustrative excerpt: "Colors didn't match Brother's chart as promised, confusing my design choices." (Primary pattern)

Why is colorfastness less reliable than expected?

- Issue timing: Fading noticed after commercial or home laundering.

- Frequency tier: Secondary but significant among frequent washers.

- Cause: Dye chemistry may not withstand harsh washing agents well.

- Impact: Work uniforms and linens lose vibrancy prematurely.

- Category comparison: Less forgiving than typical polyester threads rated for durability.

- Mitigation attempts: Using gentler detergents, but adds extra care steps.

- Result: Extra maintenance and potential premature replacement.

Illustrative excerpt: "Colors faded quickly after just a few washes, disappointing for work uniforms." (Secondary pattern)

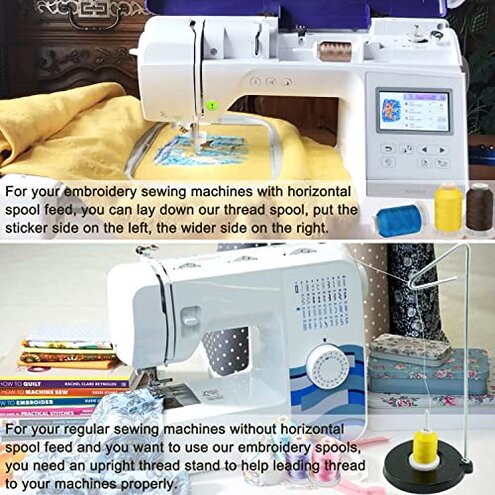

Are there compatibility issues with different embroidery machines?

- When it happens: During spool installation or first use on machines like Brother or Janome.

- Frequency tier: Edge case but reported across various device models.

- Cause: Slightly different spool dimensions or winding tension.

- Impact: Requires manual adjustments or causes thread jams.

- Category baseline: Most kits fit seamlessly; this one needs extra effort.

- Attempted fixes: Users adjust machine tension or spool holders.

- Hidden need: Buyers must be prepared for setup tweaking.

Illustrative excerpt: "Thread spool didn’t fit well on my Janome, causing stitching errors." (Edge-case pattern)

Who should avoid this

- Users needing consistent thread strength: Frequent thread breaks cause costly project delays.

- Color-critical crafters: Color mismatches undermine design accuracy.

- Professionals requiring high colorfastness: Fading threads reduce garment life and visual appeal.

- Embroidery machine owners preferring plug-and-play: Potential fit issues add setup frustration.

Who this is actually good for

- Hobbyists on a tight budget: Will tolerate occasional breaks for a large color range.

- Beginners experimenting with colors: Can accept color shifts during practice projects.

- Non-commercial users less concerned about washes: Suitable when frequent laundering isn’t expected.

- Users willing to manually adjust machines: Can handle spool fit quirks with patience.

Expectation vs reality

Expectation: Polyester embroidery threads generally maintain color and resist breakage under normal use.

Reality: This kit shows more frequent breaks and color inconsistencies, making it less reliable for uninterrupted or professional projects.

Expectation: Color charts accurately represent spool colors.

Reality: Color discrepancies require extra testing and slow down workflow.

Safer alternatives

- Choose brands with verified tensile strength: Minimizes thread breaks during long projects.

- Pick kits with consistent color charts: Avoid surprises and reduce setup time.

- Consider threads tested for colorfastness: Ideal for commercial laundering or high-wear items.

- Buy spools known for machine compatibility: Prevent installation hassle and stitching errors.

The bottom line

The main regret for this thread kit is frequent thread breakage combined with color inconsistency, which disrupts embroidery workflows. These issues exceed normal risks seen in mid-range embroidery threads, especially for users needing reliability. Buyers prioritizing durability and accurate colors should consider alternatives to avoid frustration.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.