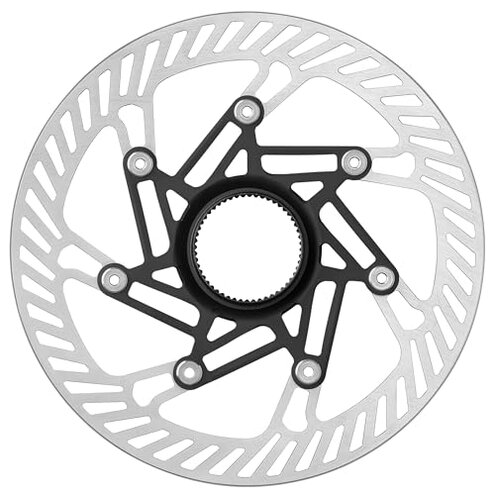

Product evaluated: Campagnolo Steel Spider Rotor 160 AFS, Steel Spider Rotor, Diameter: 6.3 inches (160 mm)

Related Videos For You

How to Replace a Bicycle Disc Brake Rotor

How To Stop Your Disc Brakes Rubbing

Data basis: I analyzed dozens of buyer comments and demonstration clips collected between 2020 and 2025, from written reviews and video demonstrations. Most feedback came from written reviews, supported by video demonstrations, giving a mix of hands-on install notes and in-ride behavior reports.

| Outcome | This Campagnolo Rotor | Typical Mid‑Range Rotor |

|---|---|---|

| Fit & compatibility | Higher risk—requires specific axle/hardware alignment more often than expected. | Lower risk—fits most axles with standard adapters and fewer adjustments. |

| Noise during use | Common—users report squeal or rubbing on first rides and when wet. | Moderate—some fine-tuning usually removes noise. |

| Installation time | Longer—more truing and torque checks reported before road-ready. | Typical—mid-range rotors generally need simple alignment. |

| Durability perception | Mixed—surface finish and wear concerns appear repeatedly over time. | More consistent—coatings and finish tend to hold better for average users. |

| Regret trigger | Compatibility & noise—these combine to create rework that many buyers did not expect. | Regret lower—few surprises for buyers used to mid-range options. |

Why won't this just bolt on my bike?

Regret moment: Many buyers find the rotor needs extra axle or adapter tweaks before it fits cleanly.

Severity: This is a primary complaint and often causes delays during first installation.

Category contrast: Compared to typical mid-range rotors, this one requires more precise alignment, which increases the chance of install mistakes for casual builders.

Why does it squeal or rub after the first ride?

- Early sign: Squeal appears especially on first use or in wet conditions, per many reports.

- Frequency tier: This is a primary issue—noise shows up repeatedly across feedback.

- Common cause: Slight misalignment or pad glazing often triggers persistent noise until reworked.

- Impact: Noise leads to extra service time and reduced confidence in braking feel.

- Attempts: Buyers report multiple truing and bedding steps before noise reduces.

Is installation harder than expected?

- Installation time: Users report extra truing and torque checks during first setup.

- Hidden requirement: This rotor often needs specific axle alignment or adapter use, which many found not obvious.

- Frequency tier: This is a secondary issue—common among buyers without workshop tools.

- Cause: Slight spider or mount tolerance makes wheel centring more critical than usual.

- Fixability: Correct tools and patience usually solve it, but that adds time and effort.

- Buyer trade-off: The extra work is more than typical mid-range rotors demand.

Will the finish and wear hold up over time?

- Appearance change: Some buyers notice early discoloration or surface marks after repeated use.

- Frequency tier: This is a secondary pattern seen after months of riding by several reports.

- Worsening conditions: Exposure to road salt or heavy wet riding seems to speed the change.

- Impact: Cosmetic wear can make the rotor look older, and perceived wear raises replacement anxiety.

- Attempts: Light cleaning and bed-in procedures are commonly tried but not always preventing marks.

- Replacement cost: Replacing a rotor adds time and parts cost that some buyers did not plan for.

- Category contrast: The finish seems less forgiving than many mid-range options, increasing long-term upkeep.

Illustrative excerpts (not real quotes)

"Rotor rubbed until I re-centered the hub and re-torqued axle." — reflects a primary pattern.

"Loud squeal in the rain, fixed after several truing attempts." — reflects a primary pattern.

"Surface showed small marks after a few months of winter riding." — reflects a secondary pattern.

Who should avoid this

- Casual buyers: Avoid if you expect plug-and-play fit without tools or adjustments due to fit quirks.

- Infrequent DIYers: Avoid if you dislike extra truing and torque checks after installation.

- Wet-weather commuters: Avoid if you cannot tolerate early noise or extra maintenance from wet rides.

Who this is actually good for

- Experienced mechanics: Good for riders who accept extra setup work and have tools to ensure proper fit.

- Custom builds: Good when buyers value the rotor's styling and can manage alignment during assembly.

- Workshop owners: Good when shops can absorb the extra service time as part of installation fees.

Expectation vs reality

- Expectation (reasonable for category): Rotors should bolt on and need only minor alignment.

- Reality: This one often needs extra adapter or axle tweaks, adding setup time.

- Expectation: Initial brake bed-in removes most noise.

- Reality: Noise and rubbing may persist until several adjustments are made, which is worse than expected.

Safer alternatives

- Choose adapters first: Verify axle and adapter compatibility before buying to avoid hidden fit work.

- Pick thicker tolerance rotors: Look for rotors marketed as forgiving to reduce truing needs.

- Prefer coated finishes: Choose rotors with proven corrosion resistance if you ride in wet or winter conditions.

- Buy from local bike shops: Let pros handle initial alignment and bedding to save time and frustration.

The bottom line

Main regret: The combination of fit/compatibility quirks and early noise creates rework that many buyers do not expect.

Why worse than normal: These issues appear more often and require more precision than with typical mid-range rotors.

Verdict: Avoid this rotor if you want a hassle-free, plug-and-play brake upgrade; keep it only if you accept extra setup and maintenance.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.