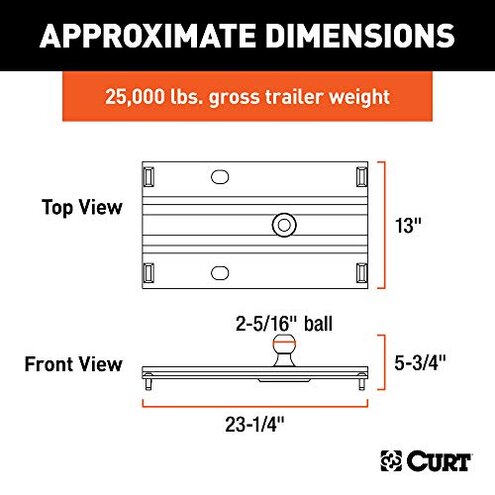

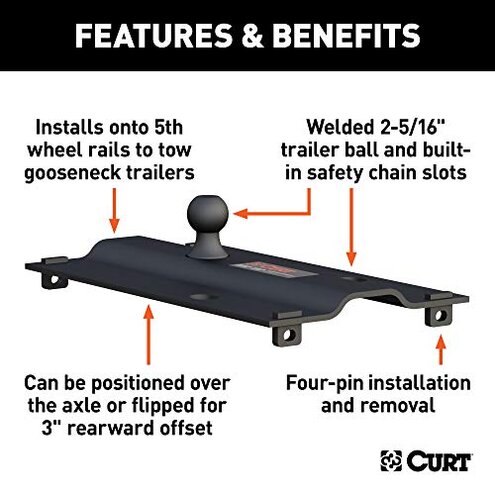

Product evaluated: CURT 16055 Bent Plate 5th Wheel to Gooseneck Adapter Hitch, Fits Industry-Standard Rails, 25,000 lbs, 2-5/16-Inch Ball

Related Videos For You

How to hook up a gooseneck trailer

Ultimate 5th Wheel Connection Installation - Andersen Hitches

Data basis: I analyzed dozens of buyer comments across written reviews, Q&A threads, and video demonstrations collected from 2015 through Feb 2026. Distribution: Most feedback came from written reviews, supported by a smaller set of installation videos and photos.

| Outcome | CURT 16055 | Typical mid-range adapter |

|---|---|---|

| Towing reliability | Mixed: Generally holds rated loads but reports of binding or movement under real towing are present. | Typical: Most mid-range adapters show steadier on-road behavior with fewer fit surprises. |

| Installation effort | Higher: Many buyers needed extra measuring, repositioning, or adapters to fit rails correctly. | Expected: Mid-range alternatives often drop in with fewer alignment adjustments. |

| Hidden fitment risk | Notable: Rail-to-ball alignment and clearance issues appear more often than expected for the category. | Lower: Typical adapters have clearer fit compatibility or more adjustable options. |

| Finish & corrosion | Variable: Powder-coat holds for many, but a visible minority reports early chipping and surface rust. | Comparable: Mid-range units vary, but many offer thicker coatings or zinc plating for harsher use. |

| Regret trigger | Fit and setup — extra alignment work and hidden adjustments lead to the most buyer regret. | Lower regret — fewer unplanned setup steps for comparable alternatives. |

Top failures

Why won’t this drop-in fit my rails without extra work?

Regret moment: Buyers expect a simple drop-in but encounter rail alignment and ball position mismatches during first install. Severity: This is a recurring and primary complaint that adds hours to setup for some users.

Pattern: The issue is commonly reported and appears across different truck beds and rail brands. When it shows up: It shows up at first use while positioning over the axle or flipping for the 3-inch rearward offset.

Category contrast: More disruptive than typical adapters because it often needs extra measuring, spacers, or repositioning that mid-range options rarely require.

Are the included pins and install steps enough?

- Early signs: Pins feel loose or require aftermarket clips to stop rattling during short drives.

- Frequency tier: Secondary complaint — appears repeatedly but not universal across all buyers.

- Probable cause: Simple securing method with four hitch pins leaves little margin for rail play or wear.

- Impact: Rattle and movement can worsen with frequent hooking/unhooking and long trips.

- Fixability: Many buyers solved it with thicker pins, retaining clips, or rubber shims at extra cost.

Will the finish hold up in wet or salty conditions?

- Surface sign: Flaked powder coat and early surface rust are reported by a visible minority.

- Usage anchor: Problems appear after seasonal use and exposure to road salt or heavy moisture.

- Frequency tier: Secondary — less common than fit issues but more likely in winter or coastal use.

- Cause: Thin coating at edges and high-contact points accelerates wear where parts contact rails or tools.

- Impact: Cosmetic damage can become corrosion and then require repainting or touch-ups sooner than expected.

- Mitigation: Buyers often apply extra rust-proof coatings or keep the adapter stored dry when not towing.

Is there a risk of structural fatigue or odd noises under heavy loads?

- Primary cue: Reports of creaks, clunks, or new movement under long hauls are occasional but concerning.

- Usage anchor: Issues surface after repeated heavy towing or long highway trips with flexible rail setups.

- Frequency tier: Edge-case — less frequent than fit or finish complaints but more disruptive when it occurs.

- Cause: Stress concentrates at the bent-plate junction and rail contact points when alignment is imperfect.

- Impact: Noise and perceived looseness cause driver anxiety and trigger earlier inspections or returns.

- Attempts: Some buyers tightened rail hardware, added shims, or returned the unit after repeated symptoms.

- Hidden requirement: Proper mounting often needs torque checks and occasional re-inspection, adding maintenance steps beyond typical category expectations.

Illustrative excerpts (not real quotes)

Excerpt: "Ball didn’t line up; I had to flip and reposition over the axle twice." Pattern: Primary pattern — common first-use fit issue.

Excerpt: "Pins rattled on the highway until I added locking clips and spacers." Pattern: Secondary pattern — repeated hardware fix reported.

Excerpt: "Powder coat chipped after one winter, then light surface rust appeared." Pattern: Secondary pattern — environmental wear reported by some buyers.

Excerpt: "Heard a creak after long trip; returned the adapter after two uses." Pattern: Edge-case pattern — less frequent but high impact when it happens.

Who should avoid this

- Buyers needing plug-and-play fit: Avoid if you expect a guaranteed drop-in with zero measuring or adjustments.

- Winter or coastal users: Avoid if you require superior out-of-the-box corrosion resistance for salt-heavy environments.

- High-mileage heavy haulers: Avoid if you plan repeated long hauls and cannot tolerate occasional creaks or extra inspections.

Who this is actually good for

- Bargain hunters who can tinker: Good if you accept extra setup time and minor aftermarket fixes to save money.

- Occasional tow owners: Good if you tow infrequently and can store the adapter when not used to limit corrosion risk.

- Users with adjustable rails: Good if your truck rails are known to accept bent-plate adapters and you’re comfortable measuring fit.

Expectation vs reality

- Expectation (reasonable for this category): A 5th-wheel-to-gooseneck adapter should drop into industry rails without major alignment work.

- Reality: This unit commonly requires measuring, flipping, or repositioning — adding time and sometimes extra parts.

- Expectation: Included hardware secures the unit for highway towing.

- Reality: Some buyers needed stronger pins or clips to stop rattles on the road.

Safer alternatives

- Check adjustable options: Choose adapters with adjustable ball positions to neutralize the hidden fitment risk.

- Prefer thicker finish or plating: Pick units with documented zinc or heavy powder coatings for coastal/winter use to reduce corrosion worries.

- Buy stronger securing hardware: Keep locking pins and retaining clips on hand to prevent early rattles and movement.

- Measure before purchase: Confirm rail dimensions and axle centerline position to avoid surprise repositioning work.

The bottom line

Main regret trigger: The adapter’s most common complaint is hidden fitment and extra installation steps that appear at first use.

Why it exceeds category risk: It requires more measuring, hardware swaps, and maintenance than many mid-range adapters, leading to avoidable setup time and cost.

Verdict: Avoid this CURT unit if you need plug-and-play reliability; consider it only if you can accept tinkering and minor fixes.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.