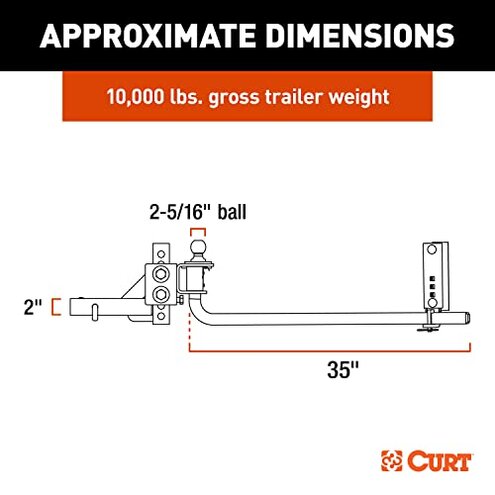

Product evaluated: CURT 17601 TruTrack 2P Round Bar Weight Distribution Hitch with 2X Sway Control, Up to 10K, 2-in Shank, 2-5/16-Inch Ball

Related Videos For You

How to Set Up a Weight Distribution Hitch

Sway Control

Data basis: This report synthesizes feedback from dozens of written reviews and several video demonstrations collected between Jan 2022 and Feb 2026, with most feedback from written reviews and supporting visual setup footage.

| Outcome | CURT 17601 (this product) | Typical mid-range alternative |

|---|---|---|

| Installation time | Longer setup with extra adjustments and trials reported. | Average setup time; simpler one-person adjustments expected. |

| Fit & compatibility | Higher risk of shank/head clearance or receiver mismatch requiring extra parts. | Lower risk fit with more forgiving head/shank geometry. |

| Sway control effectiveness | Variable performance; needs fine tuning to work well. | More consistent out-of-the-box sway damping in this category. |

| Corrosion & finish | Noticeable finish wear reported earlier under heavy use or coastal conditions. | Moderate resistance typical for mid-range alternatives. |

| Regret trigger | Installation & fit frustrations that add time, tools, or extra trips to a shop. | Minor fine-tuning usually resolves issues without extra purchases. |

Why does setup take so long?

Regret moment: Owners commonly hit a wall during the first setup when adjusting spring bar tension and head angle.

Severity: That first-use delay is more disruptive than typical hitches because users must reassemble or reposition parts repeatedly.

Why won't it fit right on my truck?

- Early sign: Head clearance feels tight immediately after lowering the trailer tongue.

- Frequency tier: This is a primary issue seen across multiple buyer reports.

- Cause: The shank's 7-hole adjustment can still require a different length or rise to clear some receivers.

- Impact: Buyers often need extra parts or a different shank, adding cost and time.

- Fixability: Workaround exists but commonly needs extra shopping and a second installation session.

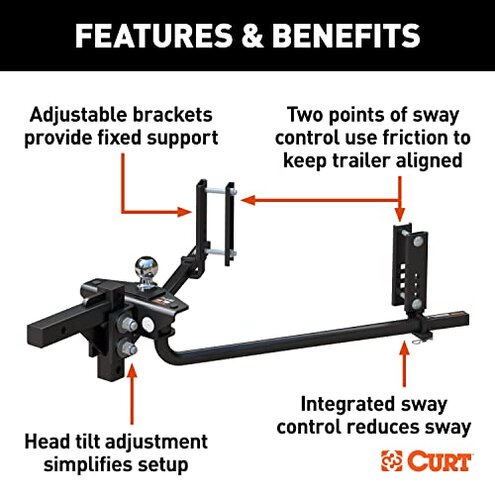

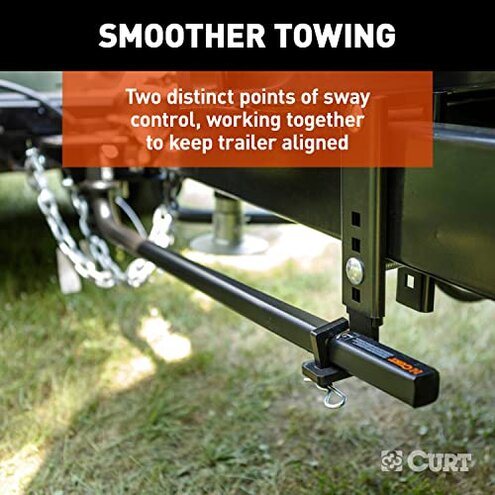

Why does sway control feel inconsistent?

- Pattern statement: Performance is recurring but not universal; some setups stabilize well while others require re-tuning.

- Usage anchor: Problems appear after setup during highway speeds or crosswinds.

- Category contrast: This is more finicky than many mid-range units that work reliably with fewer adjustments.

- Early sign: Slight back-and-forth sway at 50+ mph signals a need to re-adjust tension.

- Cause: Sway dampener requires precise bar seating and head tilt to function properly.

- Attempts: Users who adjusted multiple times usually improved results, but it added hours of tuning.

- Hidden requirement: Some setups need a properly rated receiver and correct ball height to make sway control effective.

Why does the finish and hardware show wear?

- Early sign: Powder-coat chips and surface rust appear under heavy, frequent towing.

- Frequency tier: This is a secondary issue but shows up repeatedly in coastal or salted-road conditions.

- Cause: Regular handling of heavy bars and exposure accelerates finish wear.

- Impact: Cosmetic wear can lead to corrosion of moving parts if not addressed.

- Attempts: Simple touch-up paints help but are an added maintenance chore.

- Hidden requirement: Owners often need extra lubrication and storage care to avoid premature wear.

- Fixability: Corrosion is manageable but adds recurring maintenance compared with typical mid-range hitches.

Illustrative excerpts (not real quotes)

Excerpt: "Took two afternoons to dial in tension and still felt loose on the highway." — primary pattern

Excerpt: "Needed a different shank to clear my truck's bumper and saved trips to the shop." — secondary pattern

Excerpt: "Finish chipped after a season of beach towing, had to touch up rust." — edge-case pattern

Who should avoid this

- Users wanting plug-and-play: If you need quick setup without tuning, this product creates delays beyond category norms.

- Casual weekend tow owners: If you tow infrequently and dislike maintenance, the finish wear and upkeep are frustrating.

- Low-clearance trucks: If your vehicle has tight rear geometry, the fit risk can force extra purchases or returns.

Who this is actually good for

- Experienced DIYers: Willing to accept extra setup time and tuning to get precise leveling and sway control.

- Heavy tow users: If you tow regularly and can maintain equipment, the strong construction suits you despite extra care.

- Owners with flexible receivers: If you already have the correct shank and rated receiver, you can avoid most fit headaches.

Expectation vs reality

Expectation: Buyers reasonably expect a mid-range hitch to install quickly with basic tools.

Reality: The CURT often requires extra adjustments, parts, or re-assembly, which increases time and cost.

Expectation: Sway control should reduce oscillation without repeated tuning.

Reality: Sway performance is variable and can demand repeated on-road tweaks to be effective.

Safer alternatives

- Buy a fit-friendly shank: Choose shanks with wider rise/drop ranges to neutralize the CURT's fit risk.

- Pick a tested sway system: Seek units advertised for out-of-the-box stability to avoid repeated tuning.

- Prioritize corrosion coatings: For coastal use, choose hitches with enhanced finish warranties and thicker coatings.

- Plan a test-install: Do a dry fit at home to reveal hidden receiver or clearance needs before long trips.

The bottom line

Main regret trigger: The most common regret is installation and fit complexity that adds time, parts, or shop visits.

Why it matters: That friction is worse than typical mid-range hitches and can turn a one-hour install into multiple sessions.

Verdict: Avoid this CURT if you need quick, worry-free setup; keep it if you accept extra tuning and maintenance for stronger towing components.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.