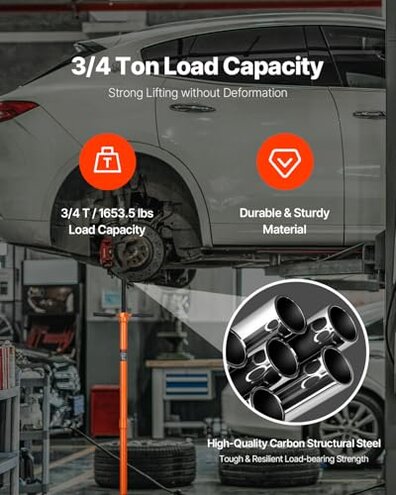

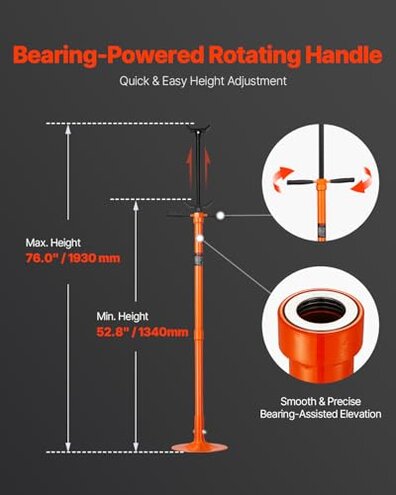

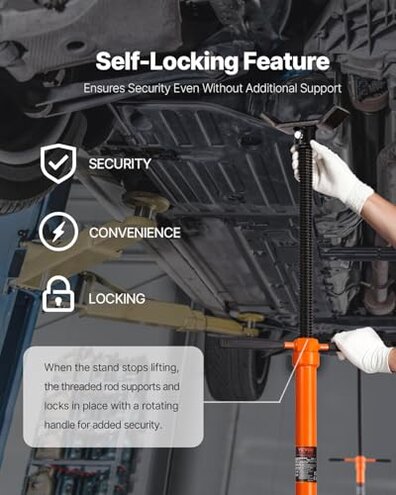

Product evaluated: VEVOR Underhoist Support Stand, 3/4 Ton Capacity Under Hoist Jack Stand, Lifting from 52.8 to 76 in, Self-Locking Threaded Screw, Bearing Mounted Spin Handle Pole Jack, Support Vehicle Components

Related Videos For You

Under Hoist Support Stand | Tool of the Week

3 Things You Probably Didn't Know About Jack Stands!

Data basis: I reviewed dozens of written buyer reports and several video demonstrations collected between January 2024 and February 2026; most feedback came from written reviews, supported by video clips and product Q&A posts.

| Outcome | VEVOR US075 | Typical mid-range stand |

|---|---|---|

| Stability under load | Higher wobble reported during use under the vehicle. | More stable with wider bases and firmer locking mechanisms. |

| Height adjustment | Threaded screw can be hard to turn after use. | Smoother ratchet or larger-pitch screw for quicker adjust. |

| Durability | Thread wear and paint flaking appear in follow-up reports. | Longer lasting finishes and thicker threads common. |

| Hidden requirements | Needs extra stands and precise hoist alignment to be safe. | More forgiving of imperfect setups in the same price tier. |

| Regret trigger | High-risk wobble under load is more disruptive than expected for this category. | Lower regret due to wider bases and stronger locks. |

Top failures

Why does the stand feel wobbly under a vehicle?

Regret moment: Users notice wobble when the vehicle is lowered onto the stand.

Severity: This is a primary issue that appears repeatedly in post-purchase reports.

When it shows: Wobble appears during first use and often worsens after repeated adjustments.

Category contrast: Mid-range stands usually feel firmer; this wobble is more disruptive than expected.

Is adjustment difficult or unreliable?

- Pattern: Many buyers report the threaded screw becomes stiff or binds after light use.

- When: Problem occurs after initial setup or several turns under load.

- Cause: Coarse lubrication and thin thread finish appear frequently in reports.

- Impact: Hard-to-turn screws add time and effort to routine jobs.

- Fix attempts: Owners often resort to extra lubrication or tools to spin the handle.

What maintenance or hidden parts are required?

- Hidden requirement: Several buyers found they must use multiple stands and a level floor for safe use.

- Frequency tier: This is a secondary issue that appears repeatedly across buyers.

- Early sign: Slight tilt when loading is an early indicator of worse alignment.

- Cause: Narrow base and small contact area magnify alignment errors.

- Impact: Extra stands, shims, or blocking are needed for confidence during work.

- Fixability: Fixes are possible but add cost and setup time compared to category baseline.

Will the stand last under regular shop use?

- Pattern: Thread wear, paint flaking, and handle play show up in follow-up reports.

- When: Issues commonly appear after repeated daily handling or long projects.

- Cause: Finishing and thinner threads are repeatedly pointed to as culprits.

- Impact: Durability issues make this less suitable than mid-range alternatives for shop use.

- Attempts: Buyers attempt rust-proofing and thread reinforcements as stopgaps.

- Hidden cost: Replacement or supplemental gear is commonly required sooner than expected.

- Category contrast: This product is less forgiving than typical mid-range stands for daily heavy use.

Illustrative excerpts (not real quotes)

Excerpt: "The stand rocked when I lowered the car; felt unsafe." — primary

Excerpt: "Screw got hard to turn after a few adjustments." — secondary

Excerpt: "Needed extra blocks and another stand to feel secure." — primary

Who should avoid this

- Home mechanics who expect firm, maintenance-free stands should avoid it due to recurring wobble complaints.

- Small shops with daily heavy use should avoid it because durability issues appear sooner than normal.

- Buyers who cannot add extra stands or blocking should avoid it because it requires precise alignment.

Who this is actually good for

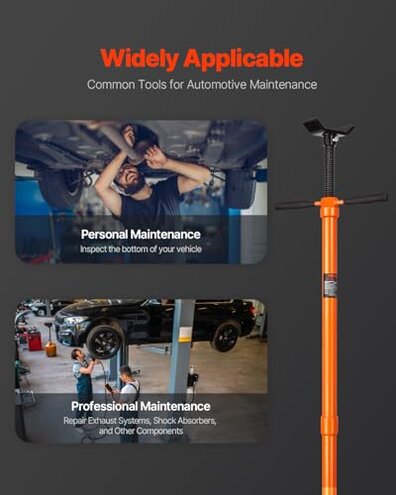

- Occasional DIYers who do light component support and can accept extra setup time and checks.

- Users who want a low-cost temporary support and can add shims or stands to improve stability.

- Non-critical tasks like positioning removable parts where minor thread stiffness is tolerable.

Expectation vs reality

Expectation: Reasonable for this category is that a 3/4-ton stand should lock and feel solid under load.

Reality: The product often shows wobble and thread wear, creating a safety and time-cost gap versus the expectation.

Expectation: Adjustment should be straightforward without extra tools.

Reality: Many buyers add lubrication or tools to operate the spin handle reliably.

Safer alternatives

- Pick wider-base stands to directly reduce the wobble and alignment sensitivity.

- Choose ratchet-style height locks to avoid the screw-stiffness failure mode.

- Buy finished-thread models or those with better corrosion protection to reduce thread wear.

- Plan for extras and budget for shims or additional stands if you consider this unit.

The bottom line

Main regret: Frequent reports of wobble and thread wear create real safety and time costs.

Why it matters: These failures are more disruptive than expected for mid-range underhoist supports.

Verdict: Avoid this stand if you need stable, long-term shop support unless you accept extra setup, maintenance, or backup stands.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.