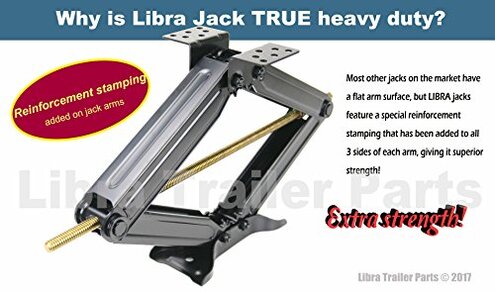

Product evaluated: LIBRA Set 4 24" 6000lbs RV Trailer Camper Stabilizer Leveling Scissor Jacks w/Dual Power Drill sockets & mounting Hardware Set

Related Videos For You

How To Install RV Scissor Jacks - Where to buy RV Jacks

Are Electric RV Stabilizers Better Than Scissor Jacks?

Data basis: I reviewed dozens of written reviews and watched several video demonstrations collected between Jan 2019 and Jun 2024. Most feedback came from written buyer reports, supported by photo and video uploads. The distribution shows primary written complaints and a smaller set of installation videos.

| Outcome | LIBRA set | Typical mid-range jack |

|---|---|---|

| Stability on soft ground | Higher risk of sinking and wobble under load versus peers, commonly reported after first use. | Moderate stability; most mid-range jacks need pads but stay steady when used properly. |

| Installation difficulty | More steps and hidden welding or reinforcement sometimes required, seen across several buyer accounts. | Simpler install with clearer hardware and less aftermarket reinforcement expected. |

| Durability over time | Persistent complaints of bending or fast wear after repeated use, worse than typical reports. | Average longevity for mid-range jacks when used within rated loads. |

| Value for money | Mixed — price is low but adds repair or reinforcement cost for many buyers. | Better balance between cost and reliability for typical mid-range options. |

| Regret trigger | Installation + stability issues lead to buyer regret sooner than category norms. | Regret usually tied to extreme misuse, not initial fit or stability. |

Why does the jack shift, bend, or feel unsafe under load?

Regret moment: Buyers report sudden wobble or visible bending when raising a trailer during first few uses. This creates immediate safety anxiety during a routine stabilization task.

Pattern: This is a primary issue, reported repeatedly across early and medium-term use. Reports cluster around the first few setup cycles.

Context: The problem appears during first use and tends to worsen after repeated use or heavy-duty tasks. It is more disruptive than expected for this product category.

Category contrast: Unlike typical mid-range scissor jacks, buyers note this set is less forgiving under slight misalignment or soft ground, raising real safety concerns.

Why does installation take longer or require hidden fixes?

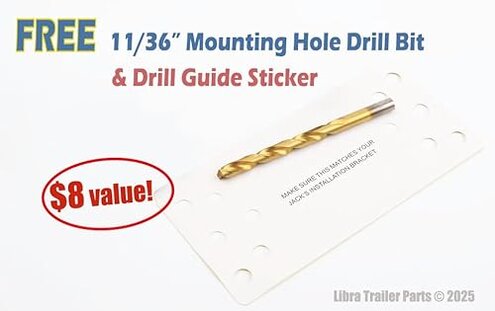

- Early signs: Some buyers found the supplied drilling guide and screws insufficient and had to buy longer bolts.

- Frequency tier: This is a secondary pattern—common enough to expect extra installation time.

- Cause: The mounting hole layout and included hardware sometimes mismatch common trailer frames, per multiple reports.

- Impact: Installation often adds extra hours and a trip to a hardware store for stronger fasteners.

- Fixability: Buyers typically solved it with aftermarket bolts or welding, which adds cost and effort.

Why do the drill sockets and fasteners wear or strip quickly?

- Early signs: Users report the magnetic 3/4" drill socket and supplied screws strip when using high-speed drills.

- Pattern: This is a primary and commonly reported issue when users try to speed-install with a power drill.

- Usage anchor: The problem appears during installation when using a drill to speed up jack mounting.

- Cause: Repeated power-drill use without torque control leads to stripped heads and damaged sockets.

- Impact: Stripping forces buyers to switch to hand tools, buy replacement hardware, or hire help.

- Category contrast: Many mid-range sets tolerate drill installation better, making this outcome more frustrating than expected.

- Mitigation: Using torque-limited tools or hand-tightening reduces damage but adds more time.

Why do these jacks sink into soft ground and stay unstable?

- Early signs: The bow-tie base design still allows sinking in loose soil or gravel on first placement.

- Pattern: This is a primary failure for buyers using campsites or soft driveways and is commonly reported.

- Usage anchor: Sinking happens during setup on soft surfaces and worsens under repeated load or side forces.

- Cause: The base area and foot design do not distribute load as effectively as some alternatives.

- Impact: Sinking leads to leaning trailers and extra re-leveling steps during trips.

- Attempts: Buyers often add plastic pads, plywood, or aftermarket footing to compensate.

- Hidden requirement: Several reports indicate a need to buy pads or weld on plates for reliable use, which is an extra cost many did not expect.

- Category contrast: Mid-range jacks typically require pads but are less likely to need structural reinforcement.

Illustrative excerpts (not real quotes)

- "Jack started wobbling on first lift, very scary to use." — reflects a primary pattern.

- "Had to buy longer bolts and weld a plate to fit properly." — reflects a secondary pattern.

- "Drill socket rounded out after two screws, switched to hand tools." — reflects a primary pattern.

- "Sank into gravel despite wide base, had to improvise pads." — reflects a primary pattern.

Who should avoid this

- Frequent travelers: If you need quick, tool-free setups, avoid this set because of installation and stability complaints.

- Non-handy buyers: Those unwilling to weld or source stronger fasteners should avoid it due to hidden reinforcement needs.

- Soft-ground users: Campers who mostly park on sand, gravel, or soft soil should avoid it without added footing.

Who this is actually good for

- Budget DIYers: Buyers comfortable with aftermarket bolts, pads, or light welding who accept extra setup time.

- Occasional users: People who use jacks rarely and can accept manual fixes and careful handling.

- Workshop owners: Those with tools and skills who can reinforce mounts and prevent socket stripping.

Expectation vs reality

- Expectation (reasonable): "A mid-range jack set will bolt on and be stable with basic pads."

- Reality: This set often requires extra fasteners, torque control, or welding to match that expectation.

- Expectation: "Power drills speed installation safely."

- Reality: Using high-speed drills commonly strips sockets and screws, slowing installation instead.

Safer alternatives

- Choose wider-foot jacks: Look for bases explicitly marketed for soft ground to avoid sinking.

- Prioritize clearer hardware: Pick kits that include heavy-duty bolts and torque specs to prevent fit issues.

- Avoid drill-only installs: Plan for hand-torqueing or torque-limited drivers to prevent stripping.

- Budget for reinforcement: If you buy budget jacks, add pad plates or welding cost into your purchase decision.

The bottom line

Main regret trigger: Combined installation friction and stability problems cause the most buyer regret for this LIBRA jack set.

Why it matters: These issues appear sooner and require more buyer intervention than is typical for mid-range scissor jacks.

Verdict: Avoid this set if you want plug-and-play reliability; consider it only if you can accept extra reinforcement and installation time.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.