Product evaluated: Anfrere 40pcs Metric Tap and Die Set, Metric Standard Rethreading Tool Kit, Coarse and Fine Threads for Cutting External and Internal Threads, Essential Repair Tool Kit with Thread Wrench

Related Videos For You

Using Taps and Dies

Data basis: I analyzed dozens of user reviews and public demo videos collected between June 2023 and January 2026. Source mix: most feedback came from written buyer reviews, supported by video demonstrations and Q&A notes.

| Outcome | Anfrere 40pc | Typical mid-range kit |

|---|---|---|

| Durability | Lower — commonly reported tooth dulling and breakage under repeated use. | Moderate — holds up for multiple projects before sharpening. |

| Thread accuracy | Inconsistent — users report misfit threads and cross-threading during first uses. | Reliable — fewer fit complaints for similar-priced kits. |

| Included tools | Basic — handles and case are usable but show quality issues. | Better organized — mid-range sets often include sturdier drivers and clearer labeling. |

| Learning curve | Steeper — hidden needs like cutting oil and careful alignment appear necessary. | Smoother — mid-range kits are more forgiving for beginners. |

| Regret trigger | High — poor durability and fit cause repeated rework and replacements. | Lower — fewer returns and fewer repair steps expected. |

Top failures

Why do threads strip or misfit?

Regret moment: Users commonly discover bad fits during the first rethreading or initial thread-cutting session. Pattern: This is a primary issue and appears repeatedly across feedback.

Usage anchor: The problem shows up during first use and gets worse with tight or hardened metals. Category contrast: This is more disruptive than expected because typical mid-range kits usually size-check and cut more reliably.

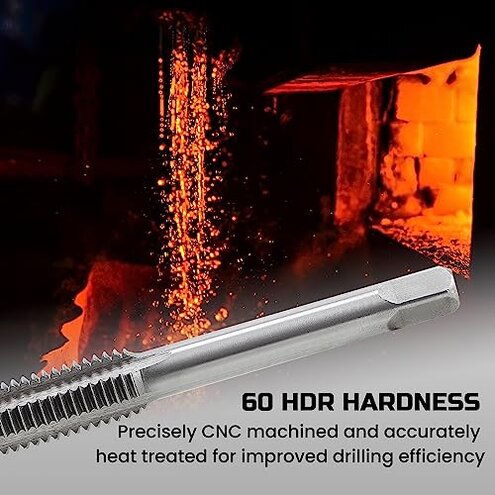

What about tool strength and wear?

- Early sign: Teeth feel dull or chip after a few uses, a commonly reported durability signal.

- Frequency tier: This is a primary issue for regular users and less frequent for one-off jobs.

- Cause: Material hardness and heat treatment appear inconsistent compared to mid-range alternatives.

- Impact: Dulling forces extra passes, adding time and risk of ruined fasteners.

- Fix attempts: Buyers report temporary fixes like light honing, but replacements were often needed.

Why are handles and accessories disappointing?

- Build quality: Handles and the die wrench are reported as flimsy in many written reviews.

- Organization: The carrying case often lacks secure slots, causing parts to shift in transit.

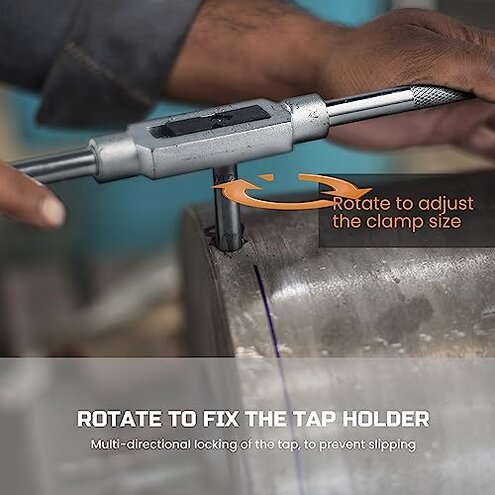

- Usability: The small tap chuck needs constant adjustment, which slows work sessions.

- Hidden requirement: Users must supply a decent wrench or vise for safe tight work.

- Attempts: Some buyers buy aftermarket handles to avoid slippage and breakage.

- Category contrast: These issues are more frequent than in typical mid-range sets where hardware is sturdier.

Is there extra setup or technique needed?

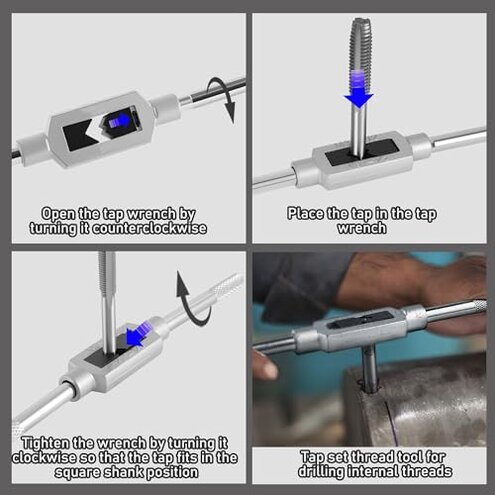

- Early sign: Beginner buyers report cross-threading during initial cuts without cutting oil.

- Frequency tier: This is a secondary issue for experienced users but common for novices.

- Cause: The set seems less forgiving to alignment mistakes than average kits.

- Impact: Requires more time, a steady hand, and proper cutting fluid to avoid damage.

- Attempts: Users often slow down, re-align, and use oil to salvage threads.

- Fixability: Workable with careful technique, but costs extra time and supplies.

- Hidden requirement: Expect to buy cutting oil and possibly replacement taps sooner than usual.

How reliable are metric sizes and labeling?

- Labeling: Occasional buyers report unclear size markings, making selection slower.

- Scope signal: This appears across both photos and written comments, so it is persistent.

- Impact: Misidentification causes wasted cuts and lost screws.

- Category contrast: Worse than expected because mid-range sets usually have clearer stamping or color coding.

- Workaround: Users often re-label or verify each tool before use.

- Repair cost: Replacements often required if a tap chips due to wrong size choice.

- Buyer note: This is a secondary issue but frustrating during timed tasks.

Illustrative excerpts (not real quotes)

Illustrative: "Taps dulled after three small jobs, had to buy replacements." — primary pattern

Illustrative: "Thread barely matched, cross-threaded on first bolt." — primary pattern

Illustrative: "Case slots don't hold dies, everything rattled during transit." — secondary pattern

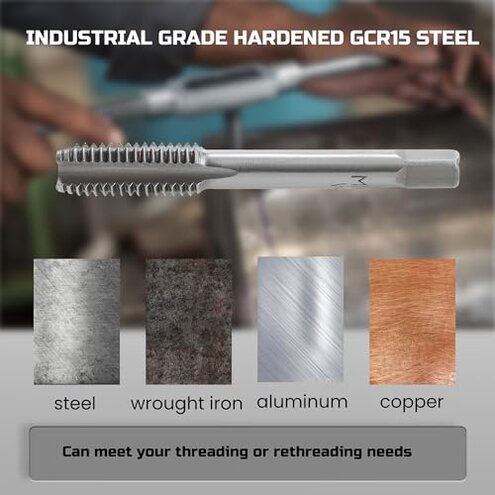

Illustrative: "Worked fine on aluminum but failed on hardened steel." — edge-case pattern

Who should avoid this

- Frequent users: Avoid if you need reliable cutting for daily or repeated metalwork due to durability concerns.

- Beginners wanting speed: Avoid if you need a forgiving kit that works out of the box without extra supplies.

- Precision jobs: Avoid if you require consistent thread accuracy for critical machine parts.

Who this is actually good for

- Hobby tinkerers: Good if you accept extra sharpening and slower setup for occasional use.

- Low-load repairs: Good for soft metals or light rethreading where demands are modest.

- Budget-minded buyers: Good if you plan to upgrade handles and add cutting oil yourself.

Expectation vs reality

- Expectation: Reasonable for this category is a kit that cuts accurate threads for several projects. Reality: This set often needs extra passes or replacements sooner than expected.

- Expectation: Tools and case come usable for transport. Reality: Many buyers report loose parts and weak handles that hamper workflow.

Safer alternatives

- Choose hardened tools: Look for kits that advertise verified heat treatment to reduce early dulling and breakage.

- Better handles: Prefer sets with cast or forged die wrenches to avoid handle failure during tight work.

- Clear labeling: Buy kits with stamped or color-coded sizes to avoid misselection errors.

- Include cutting oil: Pick sets that bundle cutting fluid or plan to buy it to reduce cross-threading risk.

The bottom line

Main regret: The most common trigger is poor thread durability and inconsistent fit that force rework.

Why worse: These failures are more disruptive than typical mid-range kits because they add replacement costs and extra labor.

Verdict: Avoid this kit for heavy or precision work; it may suffice for occasional light repairs if you accept extra upkeep.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.