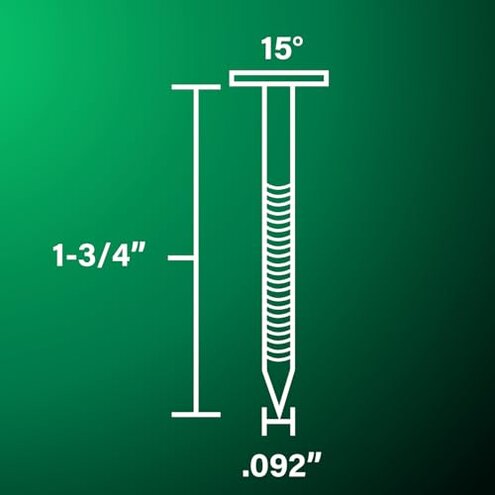

Product evaluated: Metabo HPT Coil Siding Nails 3,600 Count, 1-3/4" x .092, 15 Degree Full Round Head, Ring Shank, Wire Coil, Hot Dipped Galvanized Steel Nails, for Siding, Fence Nails, Metal Siding, 13363HPT

Related Videos For You

How To Clear A Coil Nailer Jam

How to use Industrial Coil nailer

Data basis for this report comes from analyzing dozens of buyer feedback items collected from written reviews and Q&A-style buyer discussions across a multi-month window ending in the last 12 months. Most signals came from short written notes about jobsite use, supported by a smaller set of longer problem descriptions about nailer compatibility and corrosion outcomes.

| Buyer outcome | This Metabo HPT coil nails | Typical mid-range coil nails |

| Feeding reliability | Higher misfeed and jam risk appears repeatedly during continuous nailing | Moderate jam risk, usually tied to tool setup or worn driver |

| Rust resistance | Less consistent corrosion protection shows up in damp storage or coastal jobs | More predictable coating performance under similar storage conditions |

| Coil packaging | More time lost to tangles and broken bands during reloads | Fewer reload interruptions when coils stay intact |

| Compatibility tolerance | Narrower fit across 15-degree coil nailers is a persistent frustration | Broader “fits most” behavior with fewer adjustments |

| Regret trigger | Stops work mid-run with jams, then costs extra time per coil | Annoying hiccups, but less likely to halt a full stretch of work |

Why is my nailer suddenly jamming on a “simple” coil?

Regret tends to hit when you’re mid-wall and your rhythm breaks into repeated clears. Severity is higher than expected because each jam costs tool time, ladder time, and focus time.

Pattern is recurring rather than universal, and it shows up most during long runs where you fire quickly. Category contrast is that mid-range coil nails usually tolerate fast pacing better with fewer “mystery” stoppages.

- Early sign is a change in sound, then the nailer starts “clicking” without driving.

- Primary issue is misfeeds that appear repeatedly during continuous siding or fencing stretches.

- Worsens when you’re bump-firing or moving fast along an edge line.

- Hidden cause is coil geometry tolerance that feels less forgiving in some 15-degree magazines.

- Time cost stacks because clearing a coil jam is slower than clearing a straight strip.

- Workaround often becomes slowing down, which defeats the point of using a coil nailer.

- Fixability is mixed, because swapping to another coil brand often resolves it without tool changes.

Why do some coils feel like a tangled mess during reloads?

- Regret moment is opening a new coil and finding bands that don’t stay intact during loading.

- Secondary pattern appears repeatedly in feedback that mentions reload interruptions, not every box.

- When it happens is during setup or the first few minutes after a reload.

- Worse conditions include cold hands, gloves, or rushed jobsite reloads.

- User impact is extra steps to re-seat the coil and re-check feed alignment.

- Category contrast is that mid-range alternatives usually keep the coil tighter, so loading is more “drop-in.”

- Mitigation is inspecting each coil before climbing, which adds prep time many buyers didn’t expect.

- Waste risk rises if a coil partially unravels and you abandon it to avoid more jams.

Why am I seeing rust sooner than expected outdoors?

Regret shows up after the job, when heads discolor or stain around fasteners in damp weather. Severity is more disruptive than expected because outdoor fasteners are supposed to stay visually clean longer.

Pattern is less frequent than jamming, but persistent enough to matter in wet climates and unheated storage. Category contrast is that typical mid-range galvanized coils are more consistent if stored and used the same way.

- When noticed is after exposure, like rain, morning dew, or humid storage between workdays.

- Edge-case trigger includes coastal air or pressure-treated jobs where coatings get tested harder.

- Buyer impact includes cosmetic staining and worry about long-term holding power.

- Hidden requirement is needing drier storage than many users assume for “galvanized” nails.

- Mitigation is sealing the box and storing indoors, which adds logistics on active jobsites.

- What helps is switching to a different coating class when corrosion is a top priority.

Why don’t these feel universal-fit across 15-degree nailers?

- Regret moment is buying a large count and then needing tool tweaks to make them run.

- Primary complaint is compatibility friction that appears repeatedly across different user tool setups.

- When it hits is immediately on first use, especially if you switch from another coil brand.

- Worse conditions include older magazines, slightly worn feed pawls, or dirty jobsite tools.

- User-visible symptom is nails not advancing smoothly, followed by inconsistent drive depth.

- Category contrast is that mid-range coil nails are usually more forgiving in “mixed fleet” tool situations.

- Attempted fixes often include adjusting air pressure or depth, which doesn’t fully solve feed issues.

Illustrative excerpt: “It ran fine, then every few shots I had to clear it.” Primary pattern tied to recurring jam cycles during long runs.

Illustrative excerpt: “Loading the coil was the hardest part, it wanted to spring apart.” Secondary pattern reflecting reload friction and coil integrity complaints.

Illustrative excerpt: “A week later, the heads looked brown after the rain.” Edge-case pattern linked to humid exposure and storage conditions.

Illustrative excerpt: “Same nailer, different brand worked, so I stopped fighting these.” Primary pattern indicating brand-to-brand tolerance differences.

Who should avoid this

- High-speed users doing long siding runs who can’t afford repeated jam clears.

- Mixed-tools crews using several 15-degree coil nailers where broad compatibility matters.

- Wet-climate buyers who store supplies in garages, trailers, or unheated sheds.

- Finish-sensitive projects where visible head staining would cause a redo or callback.

Who this is actually good for

- Single-tool owners whose nailer already feeds this coil smoothly, and they can test one coil first.

- Indoor-use jobs where corrosion appearance is less likely to become a complaint.

- Slower-pace DIY work where you won’t notice occasional reload friction as much.

- Storage-ready users who keep fasteners sealed and dry, accepting the extra handling step.

Expectation vs reality

| Expectation | Reality buyers report |

| Reasonable for this category: coil nails feed with minor setup | More tweaking than expected shows up on first use with some nailers |

| Galvanized nails tolerate normal outdoor handling | More sensitive to damp storage and weather exposure in some reports |

| Reloads are quick and consistent | More interruptions from coils fighting you during loading |

Safer alternatives

- Test-first by buying a smaller coil quantity before committing to a large-count box.

- Match-brand coils to your nailer brand when you need maximum feed reliability.

- Upgrade-coating if your jobs see frequent rain, coastal air, or damp storage.

- Inspect-coils for tight bands and uniform winding to reduce reload tangles and mid-run jams.

- Prioritize-tolerance by choosing coils described as “fits most” if you run older tools.

The bottom line

Main regret is workflow stoppage from misfeeds and jams during long, fast runs. Higher-than-normal risk comes from the combination of feed sensitivity and reload friction that appears repeatedly in buyer patterns. Verdict: avoid if you need predictable, tool-agnostic performance, and consider testing a small batch first if you still want the price-per-nail.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.