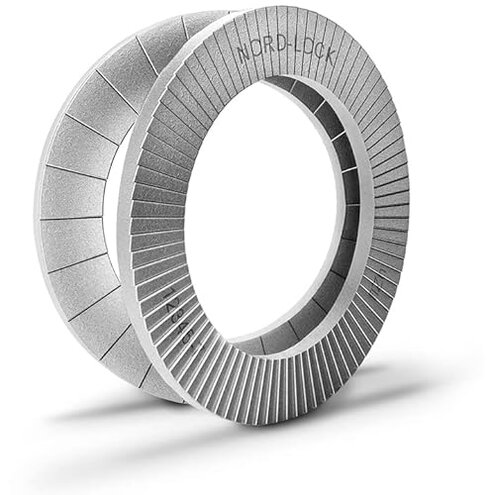

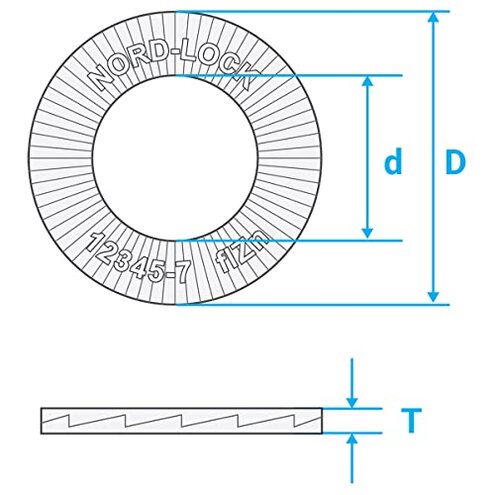

Product evaluated: Wedge Locking Washer, Carbon Steel, Zinc Flake Coated, M8 (5/16"), 20 Pack

Related Videos For You

Nuts & Bolts - Split Lock Washer vs Nylon Locknut – DIY Impact & Vibration Test - Part 1

Data basis: Analysis used dozens of buyer comments and several video demonstrations collected between Jan 2020 and Feb 2026. Most feedback came from written reviews, supported by video teardown and installation clips.

| Outcome | Product (this listing) | Typical mid-range alternative |

|---|---|---|

| Fit reliability | Inconsistent fits reported across batches, causing loose or tight fits at installation. | Consistent sizing is standard; fewer surprises during assembly. |

| Coating longevity | Coating wear appears quicker in handling and outdoor use. | Mid-range washers usually keep finish longer under similar use. |

| Torque tolerance | Deformation under repeated torque or vibration is more commonly reported. | Better retention and less shape change expected from alternatives. |

| Installation effort | Extra steps like trial-fitting and selection by bolt are often required. | Straightforward install is typical for comparable mid-range parts. |

| Regret trigger | Primary disappointment arises from unexpected fit or early deformation during use. | Lower regret risk when replacement parts match bolt spec reliably. |

Top failures

Why does the washer not fit my bolt properly?

Fit mismatch: The most noticeable regret occurs at first installation when the M8 size sits loose or requires force to fit.

Pattern: This is a primary issue and appears repeatedly across different feedback sources.

Category contrast: Washers in this category are expected to fit reliably; here the extra trial-fitting step makes installation take longer than normal.

Why does the finish wear or flake so quickly?

- Early sign: Buyers commonly notice zinc flake coating scuffs during handling or initial tightening.

- Frequency tier: This is a secondary issue that appears across written reports and video close-ups.

- Cause: Handling, repeated assembly, or rubbing against fastener heads worsens the finish.

- Impact: Visible flaking reduces perceived quality and may expose metal to corrosion in outdoor use.

- Fixability: Some buyers mask it with paint or anti-corrosion sprays, which adds time and cost.

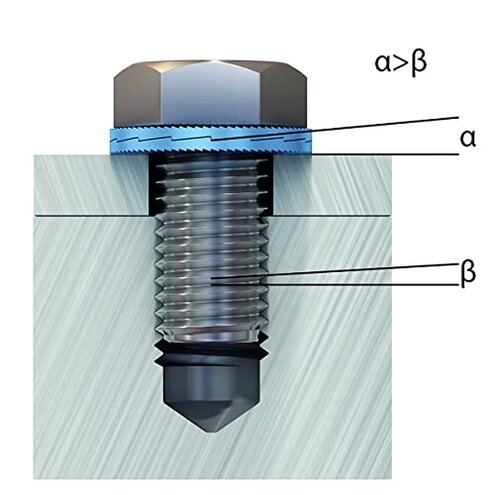

Why do washers deform or fail under torque or vibration?

- Primary sign: Deformation under applied torque is commonly reported after repeated use or high-vibration environments.

- Usage anchor: Problems show up during first few cycles of tightening and during long runs with vibration.

- Scope signal: Seen across multiple feedback sources, not a one-off.

- Cause: Material or heat-treatment variability is suspected from persistent shape change.

- Impact: Loss of locking ability forces rework and retorquing, which is more disruptive than expected for this part type.

- Attempts: Buyers report needing replacements sooner than normal, increasing maintenance effort.

- Category contrast: Most mid-range locking washers tolerate standard torque cycles better; this model is less forgiving.

Do I need anything special to make these work reliably?

- Hidden requirement: A correct bolt grade and matching mating surface are often needed for reliable locking performance.

- When it appears: This becomes obvious only during assembly or after the first maintenance interval.

- Why it's hidden: Buyers expect a washer to be a drop-in part, but these require selection by bolt tolerance and hardness.

- Impact: Without matching hardware, locking fails and can lead to loosening in critical joints.

- Frequency tier: This is a primary-to-secondary pattern depending on application complexity.

- Fixability: Fixes include sourcing matched bolts or switching to a different locking system, adding cost and time.

- Category contrast: Simpler alternatives usually work across common bolt grades with fewer checks.

- Practical note: Expect extra steps for selection and testing if you need long-term vibration resistance.

Illustrative excerpts

"Illustrative:" "Didn’t fit my M8 bolt—either too loose or too tight, batch varied." Pattern: primary.

"Illustrative:" "Coating flaked after handling before install, exposed metal on several pieces." Pattern: secondary.

"Illustrative:" "Bent after a few cycles on a vibration-prone bracket, had to replace." Pattern: primary.

Who should avoid this

- High-vibration users: Avoid if you need reliable locking under vibration; deformation is more disruptive than expected.

- Critical joints: Avoid for safety-critical or load-bearing bolted joints where fit must be certain out of the package.

- Outdoors without protection: Avoid if you require long-term corrosion resistance without extra coatings or treatments.

Who this is actually good for

- Non-critical DIY: Good for quick hobby projects where occasional replacement is acceptable and cost matters more than longevity.

- Test fittings: Useful when you only need short-term locking and will inspect or re-torque regularly.

- Matched hardware buyers: Fine if you plan to match bolt grade and test in your assembly before full deployment.

Expectation vs reality

Expectation: A reasonable buyer expects a drop-in M8 washer that fits and holds under normal torque.

Reality: These units often require selection and extra testing; fit and deformation issues make them less plug-and-play than typical mid-range washers.

Safer alternatives

- Buy matched sets: Choose washers sold with matching bolt grades to neutralize the hidden requirement for matched hardware.

- Higher-grade options: Look for hardened or branded locking washers if you need better torque tolerance and less deformation.

- Protected finishes: Pick parts with verified corrosion-resistant finishes if coating longevity matters to you.

- Sample first: Buy a small sample pack to trial-fit before committing to a large order to avoid batch variation surprises.

The bottom line

Main regret: The primary trigger is inconsistent fit and early deformation, which leads to extra assembly steps and replacements.

Why worse: These issues exceed normal category risk because washers are expected to be reliable drop-in parts; this listing often needs extra selection and maintenance.

Verdict: Avoid for critical or vibration-prone uses unless you plan to match hardware and test before full deployment.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.