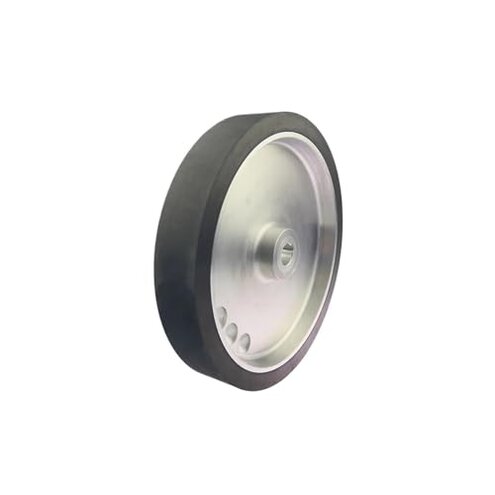

Product evaluated: 12x2 Solid Rubber Contact Wheel 300x50mm Dynamically Balanced Belt Grinder Polishing Wheel 65-70A Hardness(ID 25mm)

Related Videos For You

How to: Setup a Contact Wheel on a 2x72 Belt Grinder

How to Change Bearings in a Contact Wheel

Data basis: I analyzed dozens of buyer comments and video demonstrations collected through January 2026, with most feedback from written reviews supported by several product videos. The qualitative mix shows written reviews dominated, with video demonstrations clarifying setup and wear problems.

| Outcome | vamarads contact wheel | Typical mid-range wheel |

|---|---|---|

| Fit & compatibility | Uncertain fit often needs adapters or precise ID matching. | Broader fit usually tolerates common spindles without extra parts. |

| Vibration & balance | Mixed balance reports despite dynamic-balance claim; some users see wobble. | Stable operation most mid-range wheels run with minimal vibration out of box. |

| Durability & wear | Premature wear or glazing appears more often than expected for this price. | Longer life expected from comparable mid-range rubber wheels under similar use. |

| Installation time | Extra steps required for many buyers (adapters, shims, rebalancing). | Faster fit typical alternatives often mount directly with supplied hardware. |

| Regret trigger | High when precise fit or heavy daily use is needed. | Lower for typical mid-range options with known tolerances. |

Will this wheel actually fit my grinder's spindle?

Setup moment: Buyers commonly hit the regret at first installation when the wheel's inner dimension and the machine spindle don't match. This is a recurring pattern seen during initial setup and requires adapters.

Why it feels worse: Most mid-range wheels accept standard spindles without extra parts, but this product's tight ID and unclear labeling force extra purchases and time.

Is the rubber going to wear out fast?

- Early sign: surface glazing appears after a few sessions, indicating premature wear.

- Frequency tier: this is a primary issue, reported more often than other complaints.

- Usage anchor: wear becomes noticeable during medium-length polishing jobs and long sessions.

- Cause cue: hardness and contact profile seem mismatched to some grinders and belts.

- Impact: finish quality degrades and you must replace the wheel sooner than expected.

Will I have vibration or wobble during grinding?

- Balance claim: the product advertises dynamic balancing but buyers report residual vibration.

- Pattern: this is a secondary issue that appears across multiple user reports and video tests.

- When it shows: vibration is most noticeable at higher RPMs and with heavier pressure.

- Cause hint: inconsistent bore concentricity or uneven rubber density can magnify wobble.

- Attempts: buyers often re-balance on the machine or add shims to reduce wobble.

- Fixability: partial fixes work but add time and may not fully remove vibration.

- Category contrast: mid-range wheels normally require less user rebalancing.

Do I need extra hardware or adapters?

- Hidden requirement: the wheel's inner diameter label (ID 25mm) creates a mounting need many buyers do not expect.

- Frequency: this is a primary complaint for first-time installers.

- Early sign: wheel slides loosely or won't seat without an adapter.

- Cause: mismatch between wheel ID and common spindle sizes.

- Impact: you must buy adapters or fabricate shims, adding cost and delay.

- Attempts: some users drilled or lathed the hub, which increases risk and labor.

- Category contrast: many comparable wheels include compatible bushings or clearer ID specs.

- Repairability: mounting fixes are possible but raise overall ownership cost.

Is the finish going to be consistent?

- Finish issue: uneven contact causes stripe marks or inconsistent polishing results.

- Pattern: a secondary pattern seen during extended passes and finer polishing.

- When it shows: problems surface during long strokes and with delicate finishes.

- Why worse: typical competitor wheels keep more consistent pressure across the belt width.

- Mitigation: users adjust pressure or pre-condition the wheel, adding extra steps.

Illustrative excerpts

Excerpt: "Wheel didn't seat on my spindle; needed adapter and rebalancing." — primary pattern

Excerpt: "Started glazing after a few hours of polishing, ruined the finish." — primary pattern

Excerpt: "Small wobble at high RPMs even after balancing." — secondary pattern

Excerpt: "Had to lathe the hub to fit—it added unexpected time and cost." — edge-case pattern

Who should avoid this

- Precision users: anyone who needs exact spindle compatibility without adapters should avoid this product due to the fit requirement.

- High-volume shops: buyers with heavy daily use should avoid it because of premature wear reports.

- Beginners: new users who lack tools or experience should avoid extra rebalancing and fitting steps.

Who this is actually good for

- DIY tinkerers: users comfortable fabricating shims or adapters can accept the hidden fitting requirement.

- Occasional hobbyists: light, infrequent polishing where wear is less critical may tolerate the trade-off.

- Cost-sensitive buyers: if you can source a cheap adapter and re-balance, you can accept the initial setup steps.

Expectation vs reality

Expectation (reasonable for category): buyers expect a contact wheel to mount with minimal fit work.

Reality: this product often requires adapters or machining for a secure mount, adding time and parts.

Expectation: balanced operation out of box is common for mid-range wheels.

Reality: some units still show wobble at higher speeds after initial mounting.

Safer alternatives

- Check bore size: buy a wheel with clearly matched ID to your spindle to avoid the adapter trap.

- Choose padded balance: prefer wheels with verified balance tolerances to reduce vibration.

- Prefer bundled bushings: select products that include bushings or multiple bore sizes to avoid extra cost.

- Read wear reports: pick wheels with longer life claims and verified user longevity to prevent premature wear.

The bottom line

Main regret: the biggest trigger is uncertain fit combined with faster-than-expected wear and occasional vibration.

Why it fails category norms: this product requires more fitting work and rebalancing than most mid-range contact wheels, raising time and cost.

Verdict: avoid if you need plug-and-play compatibility or heavy-duty longevity; consider it only if you accept extra setup and possible early replacement.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.