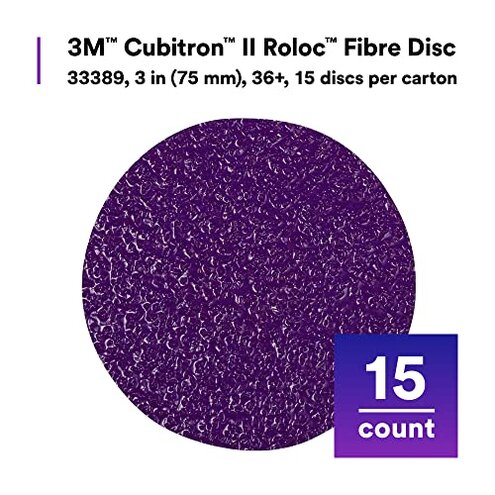

Product evaluated: 3M Cubitron II Roloc Fibre Disc, 786C, 33389, 3 in, 36+ Grit, 15 Pack, High Performance, Fast Cutting, Long Lasting

Related Videos For You

watch out !! using a angle grinder||how to mount a cutting disc onto an angle grinder correctly

Ask a Mechanic: Maintaining and Cleaning Carbon Fiber

Data basis: This report used dozens of customer-written reviews and several video demonstrations collected between 2018 and 2025, with most feedback coming from written reviews and supported by hands-on video tests.

| Outcome | 3M Cubitron II (this product) | Typical mid-range disc |

|---|---|---|

| Cut speed | Fast initially but often followed by rapid wear. | Moderate and steadier performance over life. |

| Longevity | Shorter-than-expected for many users during repeated jobs. | Typical lifespan aligns better with cost in this category. |

| Replacement cost | Higher due to faster discard rates in prolonged use. | Lower ongoing cost because discs last longer per job. |

| Work interruptions | Frequent disc swaps reported during long sessions. | Less frequent swaps during the same tasks. |

| Regret trigger | Rapid wear causes higher downtime and costs than expected. | Predictable wear that buyers plan around. |

Why am I replacing discs so often during larger jobs?

Regret moment: Buyers report the disc cuts quickly at first but needs replacement after short sessions, creating frequent interruptions.

Pattern: This is a primary and commonly reported complaint across feedback.

When it shows: Appears during long grinding tasks or back-to-back pieces, especially under sustained pressure.

Category contrast: More disruptive than most mid-range abrasive discs, which usually trade cutting speed for steadier life.

Does the disc fail prematurely under heavy use?

Early signs: Users notice abrasive glazing and loss of bite after the first few minutes on steel.

- Frequency tier: This is a primary issue reported repeatedly by buyers doing consecutive tasks.

- Cause: Commonly linked to continuous high-pressure use and long sessions.

- Impact: Leads to extra downtime and more disc swaps in the middle of jobs.

- Attempts: Users tried lighter pressure and shorter passes, with mixed success.

- Fixability: Often only solved by swapping to a new disc, adding cost.

Is there a hidden requirement I missed before buying?

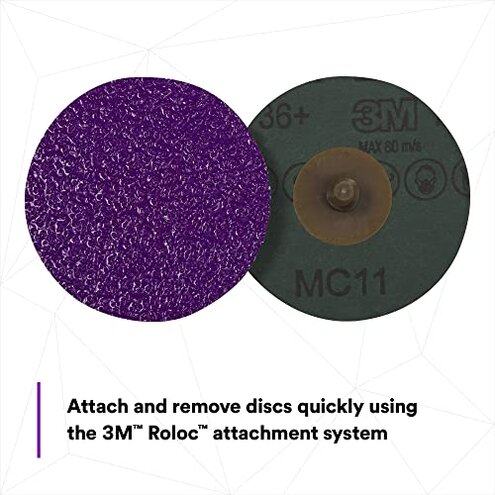

Hidden need: Several buyers found a tooling match requirement—proper backing and roloc setup matter more than expected.

Context: The problem appears during first setup when using different backers or cheap adapters.

Why worse: This is a secondary burden that raises setup time and can void expected speed gains versus category peers.

Will performance drop after the first few uses?

- First use: Strong cut performance initially, then noticeable decline in subsequent short sessions.

- Frequency tier: This is a secondary but persistent report across users who cycle discs.

- Symptoms: More heat buildup and less sharpness after repeated mounting.

- User workaround: Rotating discs more often increases cost and handling time.

- Hidden costs: Extra PPE, disposal, and time spent swapping are often under-counted.

- Long sessions: Performance worsens under long continuous use compared with standard discs.

Are safety or attachment issues a concern?

- Attachment fit: Some buyers found roloc loosening when using worn backers.

- Edge cases: This is an edge-case but can cause mid-job stops if not checked.

- When noticed: Shows up after repeated mount/dismount cycles or using incompatible backers.

- Impact: Can add inspection time and occasional rework to confirm secure fit.

- Preventive step: Using OEM backing or new adapters reduces this risk.

- Category contrast: More demanding than many mid-range discs, which tolerate mismatched backers better.

- Fixability: Replace backing or switch to compatible holders to avoid interruptions.

Illustrative excerpts

"Cut fast but needed replacement midway through a panel." — reflects a primary pattern.

"Worked great first pass, dull by second pass on the same job." — reflects a secondary pattern.

"The roloc loosened after several remounts; lost time checking fit." — reflects an edge-case pattern.

Who should avoid this

- High-volume pros: Avoid if you run long sessions and can't accept frequent swaps and higher recurring cost.

- Budget-conscious buyers: Avoid if you expect low replacement cost over many jobs.

- Users with mixed tooling: Avoid if you use varied or cheap adapters and can't meet the backing requirements.

Who this is actually good for

- Short, critical cuts: Good for buyers who need fast initial cut for brief jobs and accept replacements.

- Occasional use: Suitable for users who only do infrequent tasks and value initial speed over lifespan.

- Specialist finish work: Works when you need high bite for a narrow task and can swap discs between parts.

Expectation vs reality

Expectation (reasonable for this category): Buyers expect abrasive discs to lose some bite after heavy use.

Reality: For this product, buyers report a faster-than-expected decline, causing more swaps and downtime than typical mid-range discs.

Safer alternatives

- Choose durable brands: Pick discs marketed for extended life to reduce replacement frequency.

- Match backing: Use OEM roloc backing to avoid the attachment issues noted above.

- Test sample packs: Try a small pack under your exact workflow to confirm lifespan before bulk buying.

- Rotate tools: Alternate discs and lighten pressure to limit premature glazing.

The bottom line

Main regret: Rapid wear and frequent replacements are the clearest buyer pain point for this product.

Why it matters: That wear rate creates higher downtime and costs than most mid-range alternatives under repeated use.

Verdict: Avoid if you run long, continuous jobs or need predictable lifetime; consider it only for short, high-speed tasks.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.