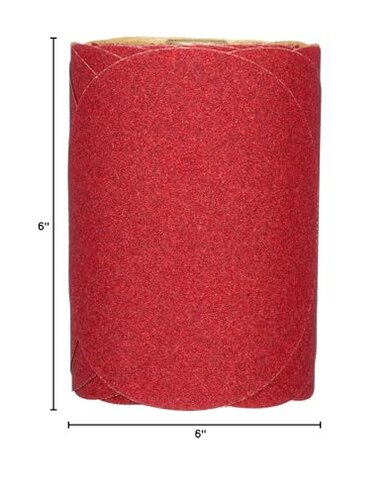

Product evaluated: 3M Stikit Red Abrasive PSA Disc, 01116, 6 in, P80, 100 Disc Roll for Auto Sanding, Primer Sanding, Rough Feather Edging

Related Videos For You

Newbie Tool Tip: Replacing a Sanding Disc

Best Auto Body Sandpaper Grits

Data basis: I examined dozens of buyer comments and several demonstration videos collected between 2015 and 2025. Most feedback came from written reviews, supported by video demonstrations and photos. The distribution leaned toward hands-on users reporting sanding performance and pad fit problems.

Comparative risk snapshot

| Outcome | 3M Stikit P80 (this) | Typical mid-range disc |

|---|---|---|

| Adhesion to pad | Higher risk: PSA release or lifting reported repeatedly after short use. | Lower risk: Most mid-range discs hold through normal sessions without re-taping. |

| Wear life | Poorer: Faster clogging and grit loss on primer and filler work. | Average: Mid-range options usually last longer before clogging. |

| Compatibility | Hidden requirement: Product label suggests specific backup pads for best fit. | More forgiving: Typical discs fit a wider range of pads without fuss. |

| Setup time | Longer: Roll format and trimming add prep time and waste. | Faster: Pre-cut discs are ready to mount and replace. |

| Regret trigger | High: Adhesive failures plus rapid wear create repeated interruptions and extra cost. | Moderate: Typical discs produce fewer mid-job interruptions. |

Top failures

Why does the disc peel off my pad during sanding?

Adhesive failure: Many buyers report the PSA lifting from the backing after first use or during long sessions. This pattern appears repeatedly in hands-on comments and video demos.

Usage anchor: The problem shows up during extended sanding, especially on high-speed orbital machines or when sanding hot surfaces like primer under sunlight.

Category contrast: This is worse than most mid-range discs because those usually keep firm PSA adhesion through similar sessions, so expect more interruptions and reattaching.

Why does the disc clog and wear out so fast?

- Primary sign: Clogging appears commonly when sanding primer, body filler, or coarse paint.

- Frequency tier: This is a secondary but frequent complaint across written feedback.

- Probable cause: Coarse P80 grit and roll format combine to shed and pack debris, reducing cut rate.

- Impact: Users report needing extra discs and stopping to clear clogged surfaces more often.

- Fix attempts: Buyers tried changing pressure or backing pads, with limited improvement.

Why won't this fit my pad or machine smoothly?

- Compatibility note: The product label suggests specific backup pads (PN05576 or PN05556) which indicates a hidden requirement for low-profile backing.

- When it appears: Fit problems show up at setup when trimming discs or mounting from the roll.

- Worse under: High-RPM orbital sanders and worn pad centers make adhesion and balance worse.

- Why worse than normal: Typical mid-range discs are pre-cut and balanced; these require extra alignment and trimming.

- Attempts to fix: Users switched to recommended backup pads or purchased pre-cut discs to avoid the issue.

- Hidden cost: Additional pads or cutting tools add time and expense not obvious from the listing.

Why does the roll format add hassle and waste?

- Packaging pain: The roll requires cutting to size, which many buyers find slows job setup.

- Frequency: This is a commonly mentioned inconvenience in user comments.

- Early sign: First-time users note uneven cuts and mismatched center holes when using a utility knife or scissors.

- Impact on workflow: Repeated cutting increases downtime during multi-piece jobs.

- Why worse than category norm: Many mid-range discs are pre-cut, saving time and reducing waste.

- Attempts: Buyers used circle cutters or pre-made templates, adding gear to the workbench.

- Value trade-off: The lower per-disc cost may be offset by wasted material and extra prep time.

- Edge detail: If you dislike extra setup, this format is a repeated annoyance.

Illustrative excerpts

"Disc started peeling off after ten minutes of sanding." — primary pattern

"Clogged quickly on primer, had to swap discs constantly." — secondary pattern

"Needed a special low-profile pad to stop wobble." — primary pattern

"Cutting discs from the roll wasted time and produced uneven holes." — secondary pattern

Who should avoid this

- Professional shops: Avoid if you run long sanding sessions and need uninterrupted adhesion and consistent wear.

- Finish-sensitive work: Avoid if you can't tolerate re-taping or uneven sanding from slipping discs.

- Users without cutting tools: Avoid if you prefer pre-cut discs and minimal setup time.

Who this is actually good for

- Occasional DIYers: Good if you do short sanding tasks and can tolerate swapping discs more often.

- Cost-conscious buyers: Works if you accept extra prep time to save per-disc cost and expect to replace discs frequently.

- Users with recommended pads: Fine if you own the suggested low-profile backup pads and can trim accurately.

Expectation vs reality

Expectation: Reasonable for this category is that PSA discs stick through a full sanding session without reattaching.

Reality: Many buyers found the PSA lifts during use, causing mid-job interruptions and extra disc changes.

Expectation: Reasonable to expect roll-format discs to save money while being usable with simple trimming.

Reality: The roll added prep time and waste, making the real cost higher when factoring in cutting and replacements.

Safer alternatives

- Choose pre-cut discs: Pick pre-cut 6" discs to eliminate cutting headaches and balance problems.

- Match backing pads: Buy low-profile or manufacturer-specified backup pads to reduce adhesive and wobble issues.

- Step up grit type: For primer/filler work, consider discs labeled for clog resistance to reduce frequent swaps.

- Buy smaller packs first: Test adhesion and wear with a small quantity before committing to a 100-disc roll.

The bottom line

Main regret: The combination of PSA adhesive failures and faster-than-expected wear creates repeated interruptions and hidden costs.

Why worse: These issues exceed normal category risk because they force extra tools, recommended backup pads, and frequent disc replacement.

Verdict: Avoid for long or finish-critical sanding jobs unless you accept added prep and replacement costs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.