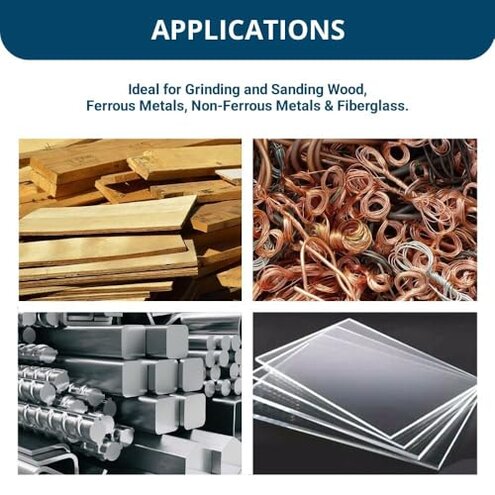

Product evaluated: Benchmark Abrasives 5 Inch Sanding Discs Ceramic Resin Fiber Grinding Disc for Grinding, Stripping on Wood, Fiberglass, Steel, Metal, 7/8" Arbor Angle Grinder Sanding Disc, 25 Pack - 24 Grit

Related Videos For You

Grinder Safety: How to Properly Use an Angle Grinder

How to Replace Sandpaper on a Disc Sander

Data basis: This report used dozens of written reviews plus video demonstrations and buyer Q&A collected between Jan 2019 and Jan 2026. Most feedback came from written reviews, supported by video clips and question threads for patterns and failure timing.

| Outcome | Benchmark Abrasives | Typical mid-range disc |

|---|---|---|

| Lifespan | Shorter life under heavy use; wears down faster than expected for a 24-grit product. | Moderate life that matches advertised duty for 24-grit discs. |

| Balance / Vibration | Noticeable wobble reported during medium-to-high RPM work sessions. | Low vibration for similar-priced competitors at the same RPM range. |

| Safety (fragmentation) | Higher risk of edge fraying and occasional shedding under heavy pressure. | Lower risk with more consistent cutting edges and containment. |

| Fit / Compatibility | Fit issues appear with some guards/backing pads; needs careful mounting. | Plug-and-play compatibility is more common with mid-range brands. |

| Regret trigger | Premature replacement and extra setup time make this product more disruptive than expected. | Predictable cost and less frequent replacements for typical alternatives. |

Why did my disc wear out so fast?

Regret moment: You notice the abrasive goes smooth or flakes within a short session. Severity often means you replace discs more than expected during one job.

Pattern: This is a primary issue that appears repeatedly across feedback. When it shows up: during first heavy passes and long grinding runs. Category contrast: More frequent replacement than most mid-range 24-grit discs causes real cost and downtime.

Is vibration or wobble a problem?

- Early sign: You feel wobble at moderate-to-high RPMs right after mounting.

- Frequency tier: This is a secondary issue seen commonly with repeated uses.

- Cause: Slight edge irregularities or inconsistent backing thickness cause imbalance.

- Impact: Vibration reduces control and raises fatigue during longer sessions.

- Attempted fixes: Buyers report trimming or re-centering, which adds extra setup time.

Will the disc shed or chip while grinding?

- Hidden risk: Edge fraying and small flakes appear under heavy pressure.

- Usage anchor: Mostly reported during aggressive stock removal and prolonged contact.

- Severity: This is a primary safety concern for high-speed grinders.

- Why worse: Unlike safer mid-range discs, shedding increases the chance of project marks or foreign chips.

- Impact to workflow: Stops work to change discs and inspect the tool guard more often.

- Fixability: Temporary by reducing pressure or RPM, but that slows work and reduces effectiveness.

- Hidden requirement: Using a stronger backing pad and stricter PPE is often needed.

Do these discs fit any grinder smoothly?

- Fit problem: Some users need extra washers or spacers to avoid rubbing against guards.

- When: Fit trouble appears at first setup and recurs with different grinder brands.

- Pattern: This is a secondary but persistent compatibility issue.

- Cause: Tolerance differences between disc center holes and machine arbors.

- Impact: Extra tools and parts are often required before safe use.

- Category contrast: More prep than typical mid-range discs that fit with standard arbors.

- Buyer workaround: Many mount on a backing pad first, adding time and cost.

- Trade-off: You keep the aggressive cutting but accept extra setup steps.

How consistent is the finish and grit quality?

Regret moment: Finish can be uneven, leaving deep scratch patterns in early passes. Trade-off: You may need follow-up sanding with finer discs.

Pattern: This is a secondary complaint that appears across varied tasks, from wood to metal. When: Noticeable on first use and under heavy stock removal, making the job take longer than expected.

Illustrative buyer phrasing (not actual quotes)

- "Wore out halfway through a 30-minute job" — reflects a primary rapid-wear pattern.

- "Disc wobble felt from the first cut" — reflects a secondary balance issue.

- "Needed extra spacer to stop guard rubbing" — reflects an edge-case fit problem.

- "Left chunks instead of a smooth finish" — reflects a secondary finish inconsistency.

Who should avoid this

- High-volume pros who need predictable lifespan and minimal changeover on long jobs.

- Safety-first operators who cannot accept any shedding risk at high RPMs.

- Buyers expecting plug-and-play who lack tools or time to add spacers or backing pads.

Who this is actually good for

- Budget hobbyists who accept shorter life for lower upfront cost and occasional replacements.

- Occasional users who work in short bursts and can stop to change discs as needed.

- Users who prefer aggressive cut and can tolerate extra finishing work afterward.

Expectation vs reality

- Expectation (reasonable): 24-grit discs remove material quickly for heavy jobs.

- Reality: The disc often wears down faster than similar 24-grit options, adding replacement cost.

- Expectation (reasonable): Discs fit standard 5" or 4.5" arbors without extra parts.

- Reality: You may need spacers or a backing pad to prevent rubbing, which adds time and expense.

Safer alternatives

- Choose balanced discs marketed for low-vibration use to neutralize the wobble problem.

- Pick reinforced-edge options or discs labeled for high-RPM safety to reduce shedding risk.

- Buy from brands listing explicit arbor compatibility to avoid extra spacers or prep time.

- Use a backing pad when you need safer containment and better fit, especially for aggressive grits.

The bottom line

Main regret: Premature wear and occasional shedding create extra replacements and safety checks.

Why it matters: These problems are more disruptive than typical mid-range discs because they add time, parts, and safety risk to common grinding jobs.

Verdict: Avoid if you need predictable lifespan, low vibration, or plug-and-play compatibility; consider only for low-volume, cost-sensitive tasks.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.