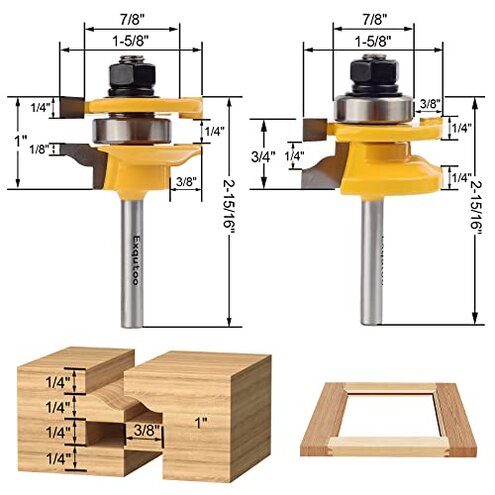

Product evaluated: Exqutoo 3PCS 1/4" Shank Router Bit Set, Raised Panel Cabinet Door Making Router Bits, Cemented Carbide Router Bits, Woodworking Tools Router Door & Window Bits (Tenon Joint Cutter Diameter: 1-5/8")

Related Videos For You

99% of Beginners Don't Know the Basics of Router Bits

Choosing and Using Raised-Panel Router Bits for Cabinet Doors

Data basis: I analyzed dozens of written buyer reviews plus several hands-on video demonstrations collected between October 2020 and January 2026. Most feedback came from written reviews, supported by video demos and recent-purchase reports.

| Outcome | This product | Typical mid-range alternative |

|---|---|---|

| Cut quality | Irregular finish on raised panels and door edges, commonly reported on first cuts. | Smoother finish with fewer early chips; more consistent across uses. |

| Fit & runout | Noticeable vibration and wobble, especially in weaker routers and with extended runs. | Lower runout in comparable mid-range bits; less vibration during long passes. |

| Durability | Chipping & dulling appears repeatedly after limited use for many buyers. | Better edge life under similar workloads in typical mid-range sets. |

| Setup ease | Hidden requirements for exact collet fit and router power that some buyers missed. | Clearer compatibility and fewer setup surprises for mid-range options. |

| Regret trigger | Cut quality + fit problems combine to cause rework and scrap risk. | Lower rework risk with typical mid-range alternatives. |

Why did my panel chip on the first cut?

Primary regret: Many buyers report chipping and fractured carbide during the first few uses when trimming raised panels. Pattern: this is commonly reported rather than universal, and it appears early, often on first use.

When it appears: the problem shows up during first-use or after light use, and worsens with harder hardwoods or aggressive depth passes. Category contrast: this is more disruptive than expected for mid-range router bits where initial edge life is usually acceptable.

Why am I getting a wobble or vibration?

- Frequency: appears repeatedly across reports as a secondary but visible issue during cutting.

- Usage anchor: shows up immediately on installation or during long, continuous cuts.

- Cause clue: inconsistent shank straightness or poor balance with 1/4" collets is commonly suspected.

- Impact: vibration causes rough edges and increases the chance of chipping on thin profiles.

- Fix attempts: buyers tried tighter collets and reduced speed with mixed success.

Do I need special router power or collets?

- Hidden requirement: several buyers found a need for a stiffer router and precise collet to avoid runout.

- Early sign: subtle wobble when hand-spinning the bit before power-on is a warning.

- Frequency tier: this is a primary setup complaint for less experienced users.

- Why it matters: inadequate router power or loose collets intensifies chipping and shortens bit life.

- Attempts: swapping to a higher-quality collet or a 1/2" shank adapter is often required.

- Fixability: workable if you have spare collets and a stronger router; not convenient otherwise.

- Category contrast: more prep and extra parts than most mid-range bit purchases demand.

Why are cuts inconsistent across uses?

- Recurring pattern: inconsistent profile depth and rough edges show up repeatedly for many buyers.

- When it happens: becomes obvious during multi-pass or long session work when heat and vibration build.

- Cause: small variations in cutter tolerance, balancing, or insert seating lead to varying results.

- Impact: requires extra sanding or re-reaming, adding time and scrap risk.

- Attempts: lowering feed rate and making shallower passes sometimes helps.

- Fixability: partial; often needs replacement bits sooner than expected.

- Hidden cost: adds extra time and abrasives, which raises real project cost versus category norms.

- Category contrast: less forgiving than typical hobby-level or mid-range bit sets.

Illustrative excerpts (not actual quotes)

"Bit chipped after two door panels; had to toss it." — reflects a primary pattern of early carbide failure.

"Noticeable wobble even in a fresh collet; finish ruined." — reflects a secondary pattern tied to fit/runout.

"Needed a 1/2" adapter and stiffer router to stop vibration." — reflects an edge-case pattern showing hidden requirements.

Who should avoid this

- Precision cabinet makers who need clean, repeatable raised-panel cuts without rework.

- Casual buyers who lack spare collets or a mid-to-high power router and expect plug-and-play parts.

- High-volume shops that need durable bits for long runs; reported chipping shortens usable life.

Who this is actually good for

- Hobbyists on a budget who will accept extra sanding and occasional replacement to save money.

- Users with upgrade parts who already own high-quality collets and a powerful router and can neutralize runout.

- Light-duty projects where a small risk of chipping won't ruin the work, like prototypes or practice pieces.

Expectation vs reality

Expectation (reasonable for this category): buyers expect mid-range router bits to provide several clean cuts before resurfacing is needed.

Reality: many reports show early chipping and fit problems producing rough edges after only a few uses.

Why worse: the need for stronger routers or precise collets increases time and cost beyond usual category expectations.

Safer alternatives

- Buy full 1/2" shank sets to reduce runout and fit issues if your router accepts them.

- Choose higher-rated carbide brands with clearer durability claims to avoid early chipping.

- Invest in a quality collet or measure runout before first use to catch hidden fit problems.

- Start with shallow passes and lower speeds to test bit behavior before full-depth cuts.

The bottom line

Main regret trigger: combined chipping and fit/runout issues increase rework and scrap risk for many buyers.

Why it exceeds category risk: the need for extra tools, collets, or a stronger router makes this set less plug-and-play than typical mid-range bits.

Verdict: avoid if you need reliable, repeatable raised-panel cuts out of the box; consider budget alternatives only if you accept extra setup and replacement costs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.