Product evaluated: Freud 4 Piece Undersized Plywood Bit Set - Ideal for Routing Accurate Grooves in Undersized Panels - 1/2" Shank, Fits 1/4"-3/4" Thickness - 89-650

Related Videos For You

99% of Beginners Don't Know the Basics of Router Bits

Router Bits for Beginners | Rockler Skill Builders

Data basis: Dozens of buyer reports and video demonstrations were reviewed between 2018 and 2025. Most feedback came from written reviews, supported by demonstration videos. The synthesis focuses on recurring, user-visible problems rather than rare praise.

| Outcome | Freud 89-650 | Typical mid-range router bit set |

|---|---|---|

| Fit accuracy | Inconsistent cuts reported; fits can be loose on undersized plywood. | Generally steady for plywood panels with fewer adjustments needed. |

| Durability | Premature dulling appears repeatedly after normal use, higher-than-normal wear. | Better retention across the category; fewer mid-term sharpening needs. |

| Setup friction | Needs calibration (depth/alignment) to get snug joints. | Lower setup burden for typical mid-range sets. |

| Storage & protection | Wooden case protects lightly but may not prevent nicks during transport. | Foam or plastic cases on alternatives provide firmer protection. |

| Regret trigger | Loose joints & quick dulling cause wasted panels and extra work. | Fewer reworks for typical mid-range choices. |

Why are my routed plywood grooves not snug?

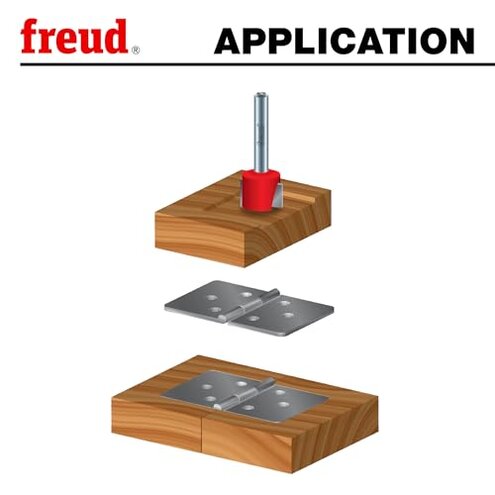

Regret moment: You cut a panel and the joint is loose, so glue gaps appear and trim work is needed.

Pattern: This is a primary issue that appears repeatedly in user reports, especially after the first setup cuts.

Usage anchor: Problem shows up during initial installation and when switching plywood thicknesses; small depth changes magnify the gap.

Category contrast: This feels worse than normal because most mid-range sets require less fine-tuning for snug plywood joints.

Do the bits dull faster than expected?

- Early sign: Users notice rougher cuts after only a few panels.

- Frequency tier: This is a secondary issue reported frequently enough to affect project timelines.

- Cause: Reports point to edge wear during routine routing of veneered plywood.

- Impact: Faster sharpening or replacement adds extra cost and downtime compared with category norms.

Why is there vibration or wobble when routing?

- Observation: Some buyers report shank runout and noticeable vibration.

- When it happens: Appears during longer routing passes or at higher RPMs.

- Scope signal: This is a persistent but not universal complaint across reviews and demonstrations.

- Cause hint: Poor collet seating or slight bit out-of-roundness magnifies wobble.

- Effect: Vibration worsens cut quality and can increase wear on both bit and router.

- Fixability: Requires collet checks, precise tightening, and sometimes replacement to cure.

Do I need extra setup, shims, or calibration to get a snug joint?

- Hidden requirement: Many buyers discover a need for fine calibration beyond “plug-and-play.”

- Early sign: Initial trial cuts show visible gaps that require depth tweaks.

- Frequency tier: This is a primary issue for users seeking tight cabinetry tolerances.

- Why it matters: Unlike some mid-range kits, this set often needs shimming or micro-adjustments to match plywood thickness exactly.

- Attempts: Buyers report extra steps like multiple test strips and adjusting router fences.

- Impact: Adds project time and material waste when precision is required.

- When worse: Problems increase when switching between veneered and composite panels.

Illustrative excerpts (not real quotes)

"Cuts felt loose, needed three test pieces to dial depth." — reflects a primary pattern.

"Edge seemed dull after routing five cabinet doors." — reflects a secondary pattern.

"Router vibrated until I rechecked the collet and retightened." — reflects an edge-case pattern.

Who should avoid this

- Precision cabinetmakers who require snug joints without extra setup.

- High-volume shops where premature dulling causes extra downtime and cost.

- Mobile tradespeople who rely on rugged, fully protective cases for transport.

Who this is actually good for

- Hobby woodworkers who accept extra test cuts and light sharpening to save upfront cost.

- Occasional DIYers making one-off cabinets who can tolerate extra setup time.

- Users comfortable with tuning (collet checks and depth trimming) to achieve snug fits.

Expectation vs reality

Expectation (reasonable): Router bit sets should produce consistent grooves for undersized plywood with minimal setup.

Reality: This set often needs multiple test passes and sharpening sooner than category peers.

Expectation (reasonable): A wooden case should protect bits during transport.

Reality: The case provides basic protection but may not prevent nicks if jostled.

Safer alternatives

- Choose bits with stronger edge retention to reduce the premature dulling problem.

- Pick sets with precision-matched shanks or buy a test collet to reduce wobble.

- Use foam or molded cases to neutralize the light protection of the included wooden box.

- Plan for calibration time in project schedules to handle the hidden setup requirement.

The bottom line

Main regret: Users mainly report inconsistent fit and faster dulling, which leads to rework and extra sharpening.

Why it matters: These issues exceed normal category risk for buyers needing fast, repeatable results.

Verdict: Avoid this set if you need plug-and-play precision; consider it only if you accept extra setup and maintenance.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.