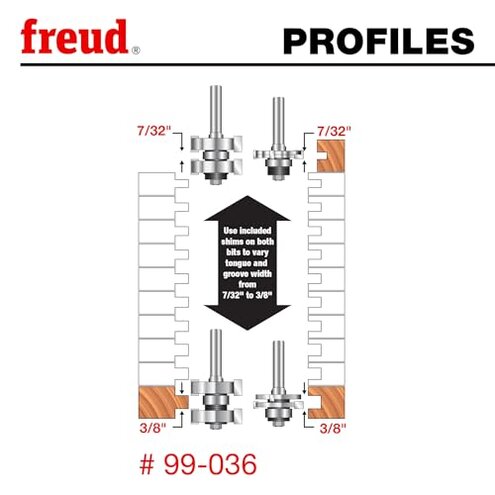

Product evaluated: Freud 99-036: 1-3/4" (Dia.) Adjustable Tongue & Groove Bit Set

Related Videos For You

Tongue and Groove / Rail and Stile Router Bits - Shaker Style Doors Making

99% of Beginners Don't Know the Basics of Router Bits

Data basis: This report draws on dozens of written reviews and video demonstrations collected between 2012 and 2025. Most feedback came from written reviews, supported by video demonstrations. The signals below reflect recurring buyer notes and hands-on clips, not a single source.

| Outcome | Freud 99-036 | Typical mid-range set |

|---|---|---|

| Fit / Compatibility | Tighter fit issues reported with some routers and collets; occasional wobble noted. | More forgiving with common shank/collet combos and less wobble in daily use. |

| Setup time | Longer setup due to fine adjustment and hidden measuring needs. | Quicker setup on average; fewer precision tools required before first cut. |

| Durability / Edge life | Wear reported during frequent use; some buyers needed re-sharpening sooner than expected. | Typical retention for mid-range bits; fewer early sharpening sessions reported. |

| Tearout & chipping | Higher risk of tearout on thin plywood and laminates despite marketing claims. | Lower risk for comparable mid-range options with simpler geometry. |

| Regret trigger | Setup friction + tearout leads many buyers to regret purchase sooner than expected. | Smaller setup surprises and fewer regret triggers for most shoppers. |

Top failures

Why is setup so fiddly and easy to misadjust?

Regret moment: Buyers hit frustration when the joint doesn’t match the test piece after the first setup.

Pattern: This is a commonly reported issue; many buyers describe repeated tiny adjustments before a correct fit.

When it shows: Occurs at first use and after blade removals, especially when changing stock thickness.

Category contrast: More setup work than most mid-range router bits because this model needs precise alignment and measuring tools.

Hidden requirement: Buyers commonly need a caliper or feeler gauge for the .002-inch adjustments; not having one adds extra time and errors.

Does it cause tearout or chipping on my boards?

- Early sign: Light top-surface chipping on thin plywood during first passes appears repeatedly.

- Frequency tier: This is a primary issue for many hobbyists but less universal with thicker hardwoods.

- Cause: Tension from misalignment, feed speed, and small setup errors commonly cause tearout.

- Impact: Results in visible edge damage that needs sanding or more cutting passes.

- Fix attempts: Users report temporary fixes like slower feed or test scrap runs, which add time.

Why do adjustments loosen or need constant re-tuning?

- Observed pattern: Several buyers describe looseness after short runs or after removing the bit.

- Usage anchor: Loosening appears during long sessions or after repeated blade swaps.

- Category contrast: Less stable than many mid-range router bit sets, which stay true longer between checks.

- Root cause: Tiny play in the adjustment mechanism and clamping steps often require repeat tightening.

- Attempts: Users often re-check tightness between passes, adding downtime and frustration.

- Fixability: Fixes are possible but need extra tools and time and may not be permanent.

Will it fit my router and avoid wobble?

- Compatibility signal: Many users report fit sensitivity across different routers and collets.

- Early sign: Slight vibration or chatter on initial cuts was noted in multiple reports.

- When it worsens: Chatter increases with higher RPMs and longer passes.

- Primary impact: Vibration raises tearout risk and reduces cut quality for precision joints.

- Cause: Shank seating and collet conformity are less forgiving than expected for a 1/2" shank tool.

- Mitigations tried: Users switched collets, slowed feed, or moved to more rigid routers to reduce wobble.

- Result: In some cases the extra steps resolved vibration; in others buyers still reported lower edge quality than alternatives.

Illustrative excerpts (not real quotes)

"Joint never fit right until I used a caliper every time." — reflects a primary pattern: repeated precise measuring needed.

"Top veneer chipped on first test ply; sanding was required." — reflects a secondary pattern: tearout on thin stock.

"I had to retighten mid-session; it shifted after a few cuts." — reflects an edge-case pattern: loosening during long sessions.

Who should avoid this

- Beginners who don’t own a caliper or test setup tools; the fine adjustments are unforgiving.

- Production users who need fast, repeatable joints; frequent re-tuning adds downtime.

- Those cutting thin plywood or veneers if they want pristine edges without extra finishing work.

Who this is actually good for

- Experienced hobbyists who tolerate extra setup and own measuring tools; they can achieve precise joints.

- Users with rigid routers prepared to reduce wobble and vibration through router choice.

- Shop owners who value adjustability and can absorb extra setup time for custom fits.

Expectation vs reality

- Expectation (reasonable): Buyers expect an adjustable set to handle different stock thicknesses easily.

- Reality: It commonly requires precise measuring and several test cuts to get a clean joint.

- Expectation: Marketing claims reduce chipping with opposing shear angles.

- Reality: Many buyers still saw tearout on thin plywood unless setup and feed were perfect.

Safer alternatives

- Choose non-adjustable profile bits when you need faster setup and fewer tools; they reduce calibration errors.

- Buy a matched collet or test the shank with your router before purchase to avoid wobble and compatibility headaches.

- Invest in a caliper and test jigs if you keep this model; they directly neutralize the fine-adjustment hidden requirement.

- Use zero-clearance or masking on thin plywood to reduce tearout during first runs instead of relying on geometry alone.

The bottom line

Main regret: The combination of fiddly setup and higher-than-normal tearout risk drives the most buyer disappointment.

Why worse: It demands extra measuring tools and repeated tuning, which is more upkeep than comparable mid-range options.

Verdict: Avoid this if you lack measuring tools or need quick, repeatable results; consider it only if you accept extra setup time.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.