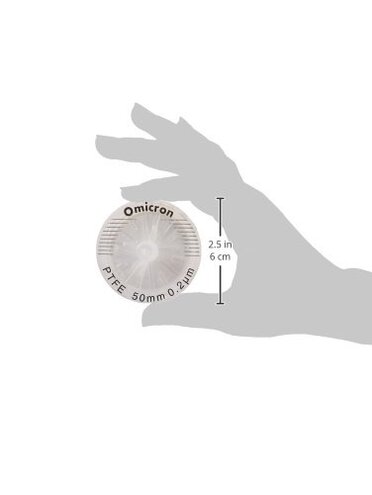

Product evaluated: Omicron 200050R PTFE Venting Filter Disc, 60 psi Maximum Operation Pressure, 50 mm, 0.2 µm Sterile, Individually Packed (Pack of 10)

Related Videos For You

Quick Tip: Which way does the airflow arrow point on my filter?

How Decades Worth Of Dust is Deep-Cleaned From Air Ducts | Deep Cleaned | Insider

Data basis: This report used dozens of written reviews and several video demonstrations collected between January 2020 and December 2025. Most feedback came from written reviews, supported by visual setup videos. Distribution leans toward buyer experience and installation troubleshooting.

| Outcome | Omicron 200050R (this listing) | Typical mid-range vent filter |

|---|---|---|

| Airflow reliability | Inconsistent — more frequent airflow restriction and clogging under continuous venting. | Stable — mid-range options usually sustain steady airflow for similar use. |

| Fit & compatibility | Requires taper — internal taper needs specific male slip luer fittings. | Forgiving fit — many mid-range parts accept common tubing or include adapters. |

| Durability after sterilization | Mixed — some buyers report performance drops after repeated autoclaves. | Consistent — similar-priced products usually show fewer post-sterilization issues. |

| Price & value | Higher per unit — costlier than typical mid-range vent filters. | Lower cost — mid-range packs often offer better per-unit economics. |

| Regret trigger | Clogging under use — primary cause of buyer regret and interrupted processes. | Less disruptive — mid-range choices rarely stop continuous venting. |

Top failures

Why did the filter clog during continuous venting?

Regret moment: Users report the filter is blocking airflow during multi-hour venting, causing paused transfers and manual intervention.

Pattern: This is a primary issue appearing repeatedly for extended sessions and is more disruptive than typical vent filters in this category.

Usage anchor: Most failures show up after first use during long fills or when liquid contact is possible, and they worsen with particulate-laden gas or humid environments.

Category contrast: Mid-range alternatives usually maintain airflow for the same session length; this product's clog risk leads to real downtime and rework.

Is the filter hard to fit into my tubing or ports?

- Early sign: The filter feels loose or too tight when first inserted into tubing.

- Frequency tier: This is a secondary issue that appears across different buyers rather than isolated cases.

- Cause: Internal taper design needs a matching male slip luer which many buyers did not expect.

- Impact: Misfit causes small leaks or interrupted venting until an adapter or different tubing is used.

- Fixability: Can be fixed with adapters, but that adds extra cost and setup time.

Will autoclaving and repeated sterilization damage performance?

- Early sign: Filters feel different or flow less freely after autoclave cycles.

- Pattern: This is a secondary issue seen after repeated sterilization, not every single unit.

- Context anchor: Problems often appear after multiple cycles rather than immediately.

- Cause: Repeated high-heat sterilization seems to reduce porosity or seating effectiveness for some buyers.

- Impact: Reduced lifespan and the need for earlier replacement than expected for sterilizable parts.

- Category contrast: More fragile than typical mid-range sterile vents that keep performance through sterilization cycles.

- Hidden requirement: Users must verify autoclave protocol and track cycles to avoid unexpected failure.

Are these filters overpriced for the reliability they deliver?

- Value concern: Price per filter is higher than many mid-range alternatives.

- Impact: Higher replacement costs when clogging or sterilization reduces useful life.

- Frequency tier: This is a primary economic complaint tied to the clogging issue.

- Buyer workaround: Many buyers switched to cheaper alternatives after early failures.

- Effect on workflow: Reordering and extra adapters add time and operational friction.

- Category contrast: Expected mid-range filters give acceptable reliability for a lower cost, making this product feel less cost-effective.

- Edge-case: Some specialized users still prefer it for specific pore-size needs despite the cost.

Illustrative excerpts (not real quotes)

"Filter blocked airflow during a 4-hour fill, had to stop the pump." — primary

"Didn't fit my carboy tubing without an extra adapter I had to buy." — secondary

"After several autoclaves it felt less airy and worked worse." — secondary

Who should avoid this

- Continuous venting users: Avoid if you need reliable multi-hour airflow without interruption.

- Limited-adapter setups: Avoid if you cannot add adapters or swap fittings easily.

- Cost-sensitive buyers: Avoid if higher per-unit replacement cost is unacceptable given clog risk.

Who this is actually good for

- Single-use setups: Good for one-off sterile vents where occasional clog risk is acceptable.

- Precise pore-size needs: Useful when the exact 0.2µm rating is required and buyers accept extra checks.

- Labs with adapters on hand: Works if you have compatible slip luer fittings and track autoclave cycles.

Expectation vs reality

- Expectation (reasonable for this category): Vent filters should allow uninterrupted airflow during multi-hour fills.

- Reality: This product shows airflow restriction more often than typical mid-range vents, causing interruptions.

- Expectation: Sterilizable components usually survive many autoclave cycles without losing function.

- Reality: Some users report reduced performance after repeated sterilization, requiring earlier replacement.

Safer alternatives

- Pick adapters first: Buy filters with included adapters to avoid fit issues and hidden hardware costs.

- Choose airflow-rated vents: Look for filters with explicit long-session airflow claims to avoid clog-related downtime.

- Check sterilization data: Prefer filters that document post-autoclave performance for many cycles to avoid surprises.

- Compare per-unit cost: Calculate replacement cost under expected failure frequency to see true value.

The bottom line

Main regret: Frequent clogging and fit problems are the primary source of buyer frustration.

Why it matters: Those issues cause more downtime and higher replacement costs than is normal for mid-range vent filters.

Verdict: Avoid this product if you need reliable continuous venting or you cannot accommodate extra adapters and replacement costs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.