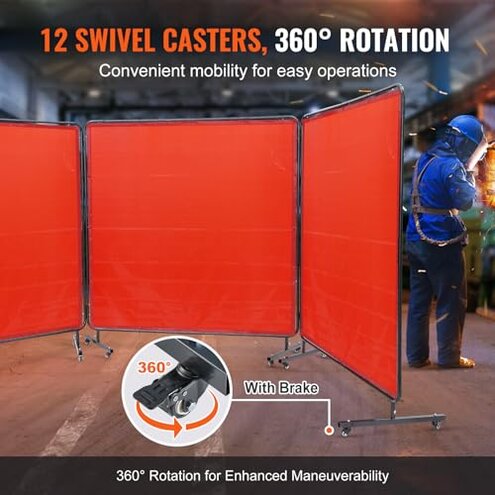

Product evaluated: VEVOR Welding Screen with Frame, 6' x 6' 3 Panel Welding Curtain Screens, Flame-Resistant Vinyl Welding Protection Screen on 12 Swivel Wheels (6 Lockable), Moveable & Professional for Workshop, Red

Related Videos For You

QuickFrame™ Welding Screen and Frame by Black Stallion® Set up Instructions

Welding Curtain #welder #fabricators #furnished #welding

Data basis: This report uses analysis of dozens of user reviews, short video demonstrations, and product Q&A collected between Nov 2023 and Jan 2026. Most feedback came from written reviews, supported by several teardown videos and troubleshooting posts.

Comparative risk snapshot

| Outcome | VEVOR 3-panel 6'x6' | Typical mid-range alternative |

|---|---|---|

| Stability while welding | Higher wobble risk reported during routine welding and when panels are moved. | Moderate stability with fewer reports of tipping under normal use. |

| Mobility and wheels | Wheel wear and locking issues on mobile use, brakes may need frequent attention. | Reliable casters designed for workshop floors in most mid-range models. |

| Material durability | Heat and tear concerns appear with heavy-duty, long sessions. | More durable fabric options often used in comparable models. |

| Setup and hidden needs | Higher assembly time and possible extra anchoring or tools required. | Quicker setup and fewer hidden hardware needs. |

| Regret trigger | Frame tipping or wheel failure during welding sessions causes immediate safety regret. | Minor annoyances tolerable for most hobby shops. |

Top failures

Will the screen tip or wobble during welding?

Regret moment: Buyers report the screen feels unstable when used near active welds or bumped while moving.

Severity: This is a primary pattern and appears repeatedly in feedback after first setup and during regular repositioning.

Category contrast: More disruptive than typical mid-range screens because instability directly creates a safety hazard and forces extra anchoring steps.

Are the wheels reliable for moving the screen?

- Early sign: Wheels may not roll smoothly on uneven shop floors during first moves.

- Frequency tier: This is a secondary complaint seen across multiple user reports.

- Likely cause: Casters and locks appear sensitive to debris and require cleaning or lubrication.

- Impact: Mobility becomes inconvenient and can increase setup time between jobs.

- Fixability: Users often need to swap wheels or add heavier-duty casters to restore reliability.

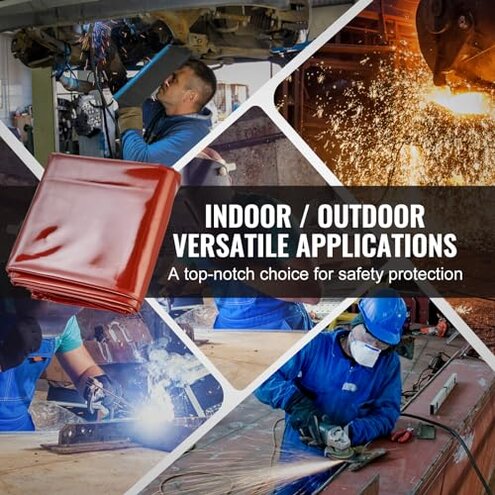

Will the curtain resist heat, sparks, and tears?

- Early sign: Small scorches or weak spots appear after prolonged, close welds.

- Pattern: Recurring but not universal; more common with heavy industrial use.

- When it shows up: Problems emerge after repeated long welding sessions or near high-temperature arcs.

- Why it feels worse: Expected-category protection seems shorter-lived, causing earlier replacement than typical screens.

- User impact: Visual shielding and UV protection degrade, increasing eye and skin exposure risk.

- Attempts to mitigate: Customers report sewing patches, adding shields, or replacing sheets sooner than planned.

- Hidden requirement: Heavy-duty shops may need to buy upgraded curtain panels separately to match workload.

How hard is setup and what extra tools are needed?

- Hidden issue: Assembly can demand extra wrenches and time beyond the included hardware.

- Early sign: Alignment struggles during first assembly, with panels awkward to square up.

- Frequency tier: Secondary but persistent among buyers assembling solo or in tight spaces.

- Cause: Frame fit tolerances require careful adjustment and occasional force to seat parts.

- Impact: Setup adds extra time and may need a second person to avoid cross-threading or misalignment.

- Fixability: Workarounds include pre-sorting parts, using thread locker, or adding extra anchors to walls/floor.

- Cost implication: Small shops should expect added time and possible small purchases to finish setup correctly.

- Category contrast: This model is less forgiving than typical mid-range options where assembly is usually straightforward.

Illustrative excerpts (not real quotes)

"Screen rocked when bumped, had to anchor it to avoid tipping." — reflects a primary pattern about stability.

"Caster kept locking; wheels felt gritty on my shop floor." — reflects a secondary pattern about mobility.

"Small burn marks after a few heavy-duty welds close by." — reflects a secondary pattern about material durability.

"Needed extra tools and a second person to line up the frame." — reflects a secondary pattern about setup difficulty.

Who should avoid this

- High-volume weld shops that run long, high-heat sessions and cannot tolerate earlier panel wear.

- Users needing instant mobility who expect smooth, maintenance-free caster performance.

- Solo buyers who cannot spend extra time or get help for assembly and alignment.

Who this is actually good for

- Occasional hobby welders who do light welding and accept some upkeep in exchange for lower cost.

- Workshops with anchoring plans that can add floor or wall anchors to remove tipping risk.

- Shops on a budget willing to upgrade casters or curtain panels rather than buy a higher-priced unit.

Expectation vs reality

Expectation: Reasonable for this category is a stable, mobile screen you can reposition without tools.

Reality: You may need extra anchoring, time, or replacement parts to reach that level of stability.

- Expectation: Wheels should roll smoothly on shop floors.

- Reality: Wheels can bind or require replacement, adding cost and downtime.

Safer alternatives

- Buy reinforced casters to directly neutralize wheel and mobility failures.

- Add floor anchors or brackets to eliminate tipping risk during active welding.

- Purchase heavier-duty curtain panels if you run long high-heat sessions to avoid early wear.

- Assemble with a second person or set aside extra time to avoid misalignment and hardware damage.

- Compare mid-range models that advertise hardened frames and industrial-grade casters before deciding.

The bottom line

Main regret: The most common trigger is frame instability or wheel problems that create safety and usability issues.

Why worse than normal: These failures are more disruptive than typical for mid-range welding screens because they affect safety and require extra fixes.

Verdict: Avoid this unit if you need reliable, maintenance-free stability for heavy or frequent welding work.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.