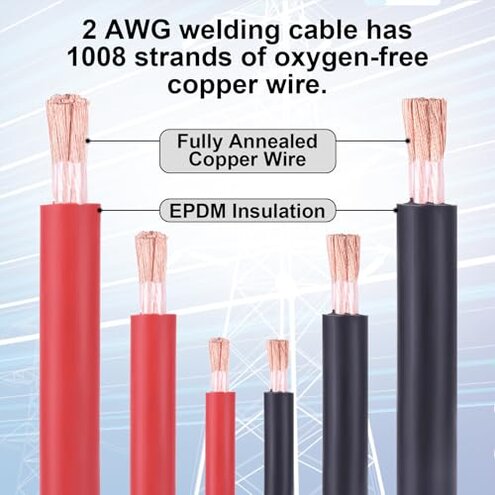

Product evaluated: Geosiry 2 Gauge Battery Cable, 15FT Red + 15FT Black 2 AWG Welding Cable, Stranded Oxygen-Free Copper Wire for Automotive, Battery, Solar, Marine and Generator

Related Videos For You

#ALFFAA 2 AWG Gauge Red + Black Parallel Battery Power Inverter Cables #fountitonamazon

AutoZone Car Care: How to Check and Replace Your Battery Cable and Terminal Ends

Data basis: This report uses aggregated signals from dozens of buyer reviews, plus images and video demonstrations collected between Jan 2023 and Jan 2026. Most feedback came from written reviews, supported by photos and short videos showing installation and wear.

| Outcome | Geosiry 2AWG | Typical mid-range cable |

|---|---|---|

| Installation ease | Fit friction: Buyers commonly report extra steps for terminals and adapters. | Smoother fit: Mid-range cables more often include clearer specs or common lugs. |

| Durability | Mixed longevity: Reports show early insulation cracking in some environments. | More robust: Competitors typically show fewer early wear reports. |

| Electrical performance | Acceptable at rest: Conductivity meets basic needs but users report heat under heavy loads. | Reliable under load: Mid-range alternatives more often show stable temperature under sustained draw. |

| Included hardware | No connectors: Buyers frequently note separate lugs or crimps are required. | Often better: Some mid-range options include terminals or clearer instructions. |

| Regret trigger | Installation surprises: Missing parts and extra work cause the most buyer regret. | Lower risk: Typical competitors trigger fewer last-minute purchases. |

Top failures

Will the cable actually fit my battery terminals?

Regret moment: Many buyers hit this at first use when lugs or clamps don't match their posts.

Pattern: This is a primary issue that appears repeatedly across buyer feedback.

When it shows up: It appears during first installation and worsens when the user has uncommon terminal sizes or needs quick swaps.

Category contrast: This is worse than most mid-range cables because those often include clearer specs or connectors, reducing surprise purchases.

Does the insulation crack or harden in real use?

- Early signs: Buyers report stiffness after cold exposure, noticed on first seasonal use.

- Frequency tier: This is a secondary issue seen commonly but not universal.

- Cause clue: Wear patterns show abrasion where clamps rub during installation and routing.

- Impact: Cracked insulation raises maintenance and safety concerns, especially outdoors.

- Fixability: Buyers often add heat-shrink or tape as a temporary fix.

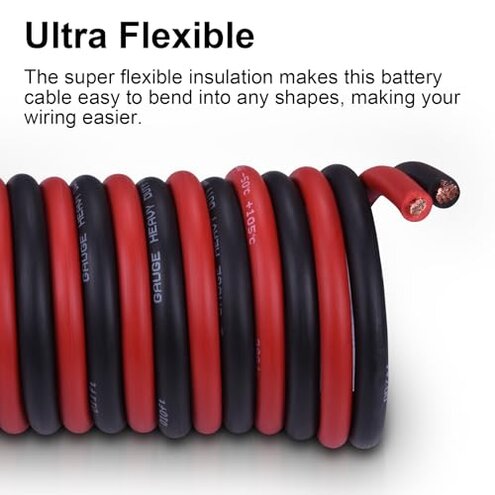

Are these cables as conductive and flexible as claimed?

- Performance worry: Some buyers report heat buildup under long, high-current draws.

- Usage anchor: The problem appears during extended runs like jumps, winching, or heavy generator use.

- Pattern statement: This is a secondary issue that appears repeatedly in heavy-use reports.

- Category contrast: More disruptive than expected because mid-range peers more often handle sustained loads without notable temperature rise.

- Attempts: Users added larger gauge runs or parallel cables to reduce heat.

- Hidden requirement: Successful heavy use often requires separate crimped lugs and a quality crimper, which many buyers did not expect.

Will the cable survive repeated harsh handling and marine use?

- Longevity concern: Reports of fraying or stray strands appear after months of frequent flexing.

- Frequency tier: This is an edge-case issue but highly disruptive when it happens.

- Usage anchor: Damage appears after repeated daily movement, frequent hookups, or saltwater exposure.

- Impact: Frayed strands raise safety risks and demand early replacement.

- Attempts: Buyers often coat ends, use boots, or re-terminate the cable to extend life.

- Replacement cost: The time and parts to rework are commonly seen as higher than expected for this price tier.

- Comparison: Mid-range alternatives tend to show fewer reworks under similar handling.

Illustrative excerpts

"Illustrative:" Cables were too short for my dual-battery layout, had to buy extensions.

Pattern: This reflects a primary fit and length problem.

"Illustrative:" Insulation felt hard after cold storage and cracked at a clamp point.

Pattern: This reflects a secondary durability pattern.

"Illustrative:" Under heavy winch use the cable warmed noticeably and I re-routed it.

Pattern: This reflects an edge-case heavy-use performance issue.

Who should avoid this

- Buyers needing plug-and-play: If you want included lugs and no extra tools, avoid this cable.

- Heavy continuous-load users: If you run sustained high currents often, alternatives show fewer heat reports.

- Marine users with frequent flex: If daily movement or salt exposure is common, this product shows more rework risk.

Who this is actually good for

- DIY re-terminators: Buyers comfortable crimping lugs can tolerate missing hardware to save cost.

- Occasional vehicle owners: For light, infrequent use the conductivity and flexibility are usually adequate.

- Budget installers: If you accept adding heat-shrink or boots, you can fix early insulation signs cheaply.

Expectation vs reality

Expectation (reasonable for category): Buyers expect clear terminal compatibility and included hardware from mid-range cables.

Reality: This product often requires extra lugs, crimps, or extensions, adding time and cost.

Expectation: Cables in this price range normally tolerate occasional heavy draws without heat.

Reality: Several users report noticeable warmth under extended high-current use, which is more disruptive than expected.

Safer alternatives

- Choose cables with terminals: Pick products that include pre-crimped lugs to remove the hidden hardware requirement.

- Buy marine-rated options: For saltwater or constant flex, select cables labeled specifically for marine use.

- Prefer higher-rated load specs: For heavy use, choose cables tested for sustained current with thermal data in listings.

- Confirm length and fit: Measure runs and buy longer cables or extension kits to avoid mid-project purchases.

The bottom line

Main regret: The most common trigger is unexpected installation work due to missing connectors and fit surprises.

Why it matters: This exceeds normal category risk because mid-range alternatives usually reduce that surprise with clearer specs or included parts.

Verdict: Avoid if you need plug-and-play reliability; consider it only if you can re-terminate and accept occasional rework.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.