Product evaluated: SZLYYDS 6 Gauge Wire 6 Awg Wires 20 FT Black + 20 FT Red, 6 Gauge Battery Cable 6awg Marine Wires, 6awg Copper Wire Welding Cable Standard with Cable Lugs Terminal Connectors and Heat Shrink Tube

Related Videos For You

How to Make Battery Cables the Right Way and the Easy Way

You Need This Tool - Episode 129 | Battery Cable Lug Crimping Tool

Data basis: I analyzed dozens of buyer comments and several video demonstrations collected between Jan 2024 and Jan 2026. Most feedback came from written reviews, supported by video demonstrations. The report weighs repeated user experiences and installation videos for pattern signals.

| Outcome | This product | Typical mid-range cable |

|---|---|---|

| Durability | Shorter-lived: Reports show early corrosion and wear under marine or outdoor use. | Moderate: Mid-range cables usually hold up with basic corrosion protection. |

| Install time | Longer: Buyers often need extra prep, re-crimping, or soldering to secure lugs. | Faster: Typical cables install cleanly with common crimp tools. |

| Corrosion risk | Higher-than-normal: Moisture ingress and plating concerns appear repeatedly after exposure. | Lower: Mid-range alternatives usually have more consistent plating and sealing. |

| Stiffness & routing | Tight bends: Larger OD and stiffer feel complicate tight routing in engine bays. | More flexible: Many competitors are easier to route in confined spaces. |

| Regret trigger | Installation fails: Misfit lugs and corrosion lead to extra work and replacements. | Occasional fixes: Typical cables rarely force rework for most hobbyist installs. |

Why did my terminals feel loose or fail after crimping?

Installation pain: Many buyers report the supplied lugs do not seat cleanly, causing loose crimps that need retuning.

Pattern sense: This is a recurring complaint across reviews and setup videos, seen most often during first installation and when using basic crimp tools.

Category contrast: This is worse than typical mid-range cables where lugs normally fit and crimp without extra steps, so it raises real replacement and labor cost.

Does this cable corrode or discolor in wet environments?

- Frequency signal: Corrosion shows up commonly after outdoor or marine exposure, not just one-off cases.

- Early sign: Buyers notice greenish or dark discoloration at lug joints after weeks of use in humid conditions.

- Cause clue: Reports point to thin plating and gaps at the lug barrel allowing moisture contact.

- Impact: Corrosion increases resistance and can cause starting or charging issues if left unchecked.

- Fixability: Some users mitigate with additional solder, sealant, or swapping to higher-grade lugs.

Will the cable be easy to route and use in tight spaces?

- Stiffness problem: The cable often feels bulkier and less flexible than expected when bending around tight corners.

- Usage anchor: This appears during first installation and worsens if repeatedly re-bent.

- Early sign: Difficulty feeding cable through conduit or behind battery trays shows up quickly.

- Performance impact: Stiffer cable forces longer routing, extra clamps, or different routing paths.

- Comparative note: More flexible alternatives reduce routing time and strain on terminals.

- Hidden cost: Expect extra time and possibly additional routing hardware to finish a clean install.

Do I need special tools or extra parts to make these reliable?

- Hidden requirement: Many buyers find a quality hydraulic crimper or soldering step is required for a reliable connection.

- When it shows: This need becomes obvious the first time a lug pulls loose or shows signs of poor contact under load.

- Skill gap: Basic hand crimpers often leave imperfect crimps that later require rework.

- Extra parts: Users commonly add proper heat shrink, dielectric grease, and higher-grade lugs.

- Time impact: These add hours to an install versus a product that crimps securely with standard tools.

- Why it matters: For battery and marine use, imperfect crimps increase safety and reliability risk compared with category norms.

- Fixability: With the right tools the cable can be made serviceable, but that raises total cost and effort.

Illustrative excerpts

Excerpt: "Lug felt loose after first drive, had to re-crimp and solder." — Pattern: primary

Excerpt: "Green corrosion at terminal after two months in humid garage." — Pattern: secondary

Excerpt: "Cable barely fit behind battery tray; needed different routing." — Pattern: edge-case

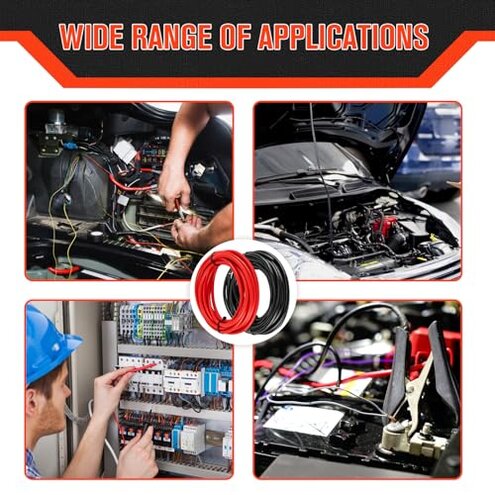

Who should avoid this

- Marine users: Avoid if you expect long-term saltwater exposure without heavy sealing and maintenance.

- Critical battery systems: Avoid for mission-critical batteries where terminal reliability is required out of the box.

- DIY beginners: Avoid if you lack crimping or soldering tools, since reliable installs often need extra tools.

Who this is actually good for

- Hobbyists with tools: Good if you have a hydraulic crimper and plan to solder and seal terminals yourself.

- Low-duty use: Okay for short-term or indoor projects where corrosion exposure is limited.

- Budget refits: Useful if you want affordable wire and plan to replace lugs with higher-grade terminals before install.

Expectation vs reality

Expectation (reasonable for category): Buyers expect a 6AWG kit to install cleanly with supplied lugs and basic tools.

Reality: Many needed extra crimping or soldering, and corrosion showed up sooner than typical mid-range options.

Why worse: That extra labor and parts turn a budget buy into a time and cost sink compared with mid-range cables.

Safer alternatives

- Buy pre-assembled kits: Look for cables with factory-crimped, heat-shrunk lugs to avoid misfit terminals.

- Choose tinned-plated lugs: Opt for confirmed marine-rated plating and full barrel seals to reduce corrosion risk.

- Prioritize flexibility: Select cables advertised as extra-flex for easier routing in tight engine or battery spaces.

- Invest in tools: If you keep this kit, buy a proper hydraulic crimper and dielectric grease to secure connections.

The bottom line

Main regret: The primary trigger is unreliable lug fit that leads to rework and early corrosion in moist environments.

Why it matters: This exceeds normal category risk because it turns a budget cable into a time and safety cost for installs needing reliability.

Verdict: Avoid for mission-critical, marine, or beginner installs unless you plan to add higher-grade lugs and use right tools.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.