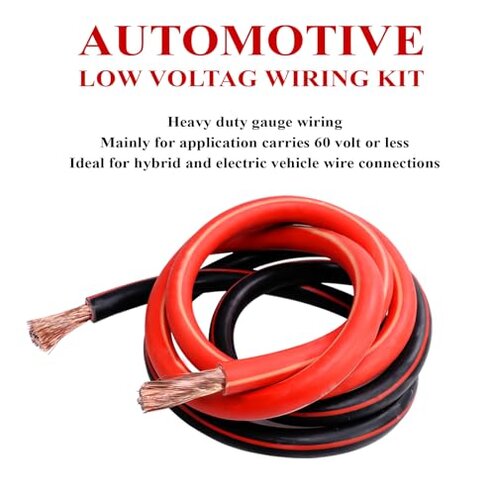

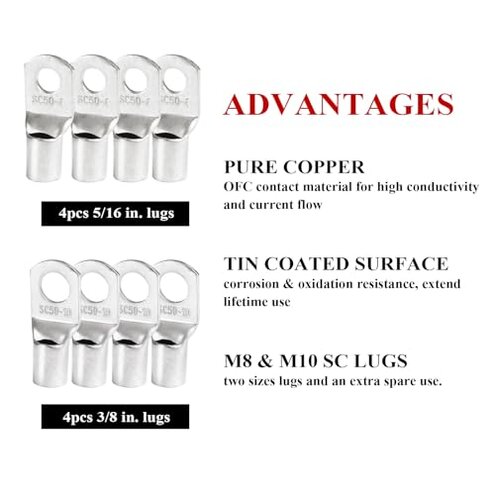

Product evaluated: SUNNAREPOON 2 Gauge Battery Cable (12 Feet Black, 12 Feet Red) - 2 AWG Copper Clad Power Welding Wire with M8 & M10 SC Connector Lugs for Car, Camper, RV, Solar Low Voltage Inverter Wiring

Related Videos For You

How to: Battery Terminal Install. Better than Factory.

BIG 3 Upgrade with 2 Gauge Welding Wire + TESTING!

Data basis: This report draws on dozens of written reviews, several customer Q&A notes, and a handful of teardown or demo videos collected between Dec 2023 and Jan 2026. Most feedback came from written reviews, supported by video demonstrations that highlight installation problems and heat signs.

| Outcome | SUNNAREPOON 2 AWG kit | Typical mid-range alternative |

|---|---|---|

| Conductivity under load | Higher risk — CCA core reports commonly indicate more voltage drop and warmth under heavy draw. | Lower risk — Pure copper equivalents usually show steadier voltage and less heating. |

| Connector reliability | Mixed — Several buyers report loose crimps and poor metal-to-metal contact. | More consistent — Mid-range kits often include pre-terminated, thicker lugs or better plating. |

| Durability & insulation | Stiff or thin — PVC insulation can be harder to route and may nick during installation. | More forgiving — Alternatives usually have softer, thicker insulation for repeated routing. |

| Installation effort | Extra steps — Buyers commonly needed better crimp tools and shrink tubing to finish reliably. | Lighter setup — Many mid-range options need less rework out of the box. |

| Regret trigger | Material trade-off — The weight/cost saving from CCA increases risk of overheating and loose connections. | Lower regret — Copper alternatives usually cost more but reduce heat and fit issues. |

Does the cable get hot or show voltage problems under heavy use?

Regret moment: Users report the cable feeling warm during higher-draw activities like winching, inverter runs, or long cranking.

Pattern: This is a primary issue that appears repeatedly in feedback and is most noticeable during the first weeks of heavy use.

Category contrast: CCA cores are less conductive than pure copper, so this feels worse than expected for mid-range automotive cable and can mean measurable voltage drop under load.

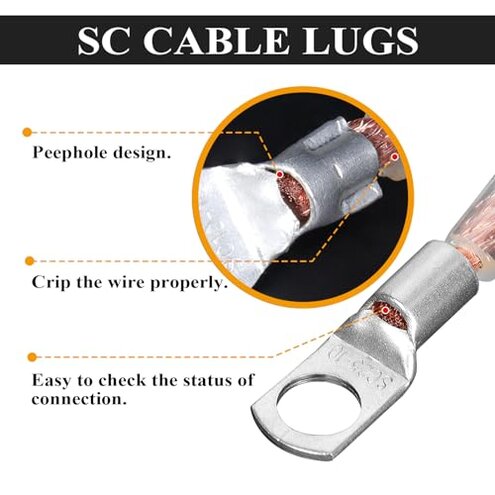

Are the lugs and crimps reliable or do they fail to seat tightly?

- Early sign: Hand-feel loose lug after crimping is commonly reported during initial installation.

- Frequency tier: This is a secondary issue seen across multiple buyers rather than an isolated complaint.

- Probable cause: Buyers note thin plating and uneven barrel inner finish that can prevent firm metal contact.

- Impact: Loose lugs increase resistance, heat, and the chance of connector failure under vibration.

- Fix attempts: Many buyers had to re-crimp using heavier tools or replace lugs with higher-quality copper versions.

Will the insulation and flexibility cause installation headaches?

- Early sign: Stiff PVC felt when pulling wire through loom or tight channels.

- Frequency tier: This complaint appears repeatedly for installations that require tight bends or long runs.

- Hidden cost: Extra time and protective sleeves are commonly needed to avoid nicking the jacket.

- Worsens when: Routing near sharp edges, through bulkheads, or around tight bends makes the problem worse.

- Category contrast: This is more frustrating than typical mid-range kits, which usually offer softer, oil-resistant jackets.

- Attempted fixes: Buyers often used additional loom, conduit, or tape to protect the cable during pulls.

Do you need special tools or rework to make this safe long-term?

- Hidden requirement: Proper heavy-duty crimpers and torque specs are often required to secure the included lugs.

- Edge-case pattern: While not universal, several buyers reported returns when they lacked a quality crimper.

- Extra steps: Buyers commonly added heat-shrink, dielectric grease, and re-crimping for safety and longevity.

- Warranty friction: Some buyers note a short warranty and extra shipping time when seeking replacements.

- Impact: The extra tools and time push total cost and effort above what buyers expect for a plug-and-play kit.

- Fixability: Re-termination with copper lugs or professional crimping typically resolves reliability concerns.

- When it shows: The need for rework is clearest at first install and when the system sees sustained current.

Illustrative excerpts

Excerpt 1: "Wire warmed under inverter load and voltage sagged noticeably." — primary

Excerpt 2: "Lug felt loose after crimping; had to replace it." — secondary

Excerpt 3: "PVC jacket nicked while pulling through the frame hole." — secondary

Excerpt 4: "Needed a pro crimper and heat shrink to finish properly." — edge-case

Who should avoid this

- High-draw users: Those running inverters, winches, or frequent heavy cranking should avoid due to heat and voltage risk.

- Non-technical buyers: People without crimp tools or experience should avoid because of the rework requirement.

- Long-run installers: Installations needing many tight bends or long routing should avoid due to stiff insulation.

Who this is actually good for

- Budget DIYers: Buyers willing to accept CCA trade-offs and who have crimp tools can save money and tolerate extra rework.

- Short-run uses: Projects with short cable runs and light loads may tolerate the conductivity limits.

- Temporary setups: Use for short-term or emergency wiring where long-term durability is not required.

Expectation vs reality

- Expectation (reasonable): Buyers expect a ready-to-install kit with reliable lugs like similar mid-range sets.

- Reality: Many needed to re-crimp or replace lugs, adding time and cost and making the experience worse than expected.

- Expectation: Wires remain cool under normal automotive loads for this category.

- Reality: CCA construction made some installations noticeably warmer during sustained draws, which is more disruptive than typical alternatives.

Safer alternatives

- Buy copper-core: Choosing pure copper cable neutralizes the core conductivity failure and reduces overheating risk.

- Pre-terminated lugs: Look for kits with factory-crimped lugs to avoid inconsistent crimps and loose connections.

- Softer jacketed wire: Pick cables with thicker, softer jackets to reduce nick and routing problems through tight spaces.

- Include proper tools: If buying this kit, plan to purchase a heavy-duty crimper and heat-shrink to mitigate lug and seal issues.

- Check returns: Buy from sellers with easy returns and longer warranty for faster replacements if you see early problems.

The bottom line

Main regret: The product’s CCA construction and inconsistent lugs create the most common failure trigger: heat and connector looseness.

Why worse: These failures are more disruptive than typical mid-range cable because they demand extra tools, replacements, or pro rework.

Verdict: Avoid this kit if you need a drop-in, long-term automotive wiring solution; consider copper or pre-terminated alternatives instead.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.