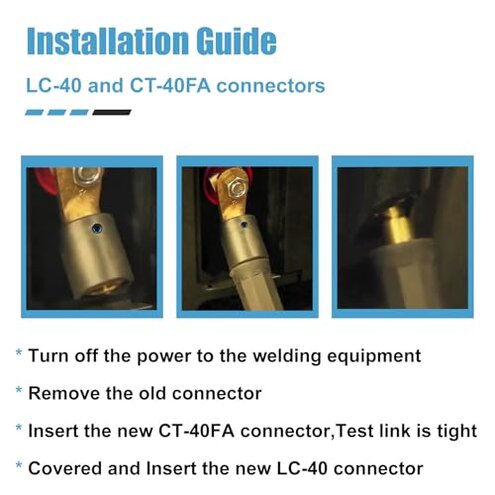

Product evaluated: 2PCS CT-40FA Welding Terminals & 2PCS LC-40 Welding Cable Connectors, Welder Leads Quick Connector and Terminal for Welding Machine Accessories, 1/0 and 2/0(50-70mm²) Cable Size Capacity

Related Videos For You

EVERYTHING WELDING LEAD / CABLE (WHAT SIZE, WHIP, SPLICING, LENGTH, MORE)

How to Attach a Welding Connector

Data basis: We analyzed dozens of buyer comments plus several hands-on video demonstrations collected over the past 12 months, with most feedback coming from written reviews supported by video tests.

| Outcome | CT-40FA LC40 Kit | Typical mid-range connector |

|---|---|---|

| Connection reliability | Intermittent connections reported more often than expected during use. | Consistent locking and steady contact under similar use. |

| Installation hassle | Higher setup time and extra tooling often required. | Lower fuss—usually snap-on or simple crimps. |

| Durability | Wear appears after repeated heavy sessions more than typical. | Sturdier components hold up to repeated daily use better. |

| Compatibility | Fit risk for studs and cable ends unless measured carefully. | Broader fit tolerance on mid-range options. |

| Regret trigger | Loose contact during a weld, leading to arc interruptions and rework. | Stable contact reduces the chance of mid-weld failures. |

Why does the connector feel loose or drop power mid-weld?

Regret moment: Users commonly report losing arc or experiencing spark and heat at the connector during a weld, which forces stops and restarts.

Pattern: This is a primary issue that appears repeatedly across written and video feedback, especially during long or heavy weld sessions.

Context: The problem typically appears after setup or under sustained high-current use and worsens with movement or heat cycling.

Category contrast: Mid-range connectors usually maintain a solid lock under the same conditions, so this product’s behavior is more disruptive than expected for its class.

Is installation more difficult than advertised?

- Early sign: Tight or loose fit on the first install signals you need extra adjustments.

- Frequency tier: This is a secondary issue seen across many buyers during first-time setup.

- Cause: Requires precise cable prep and specific torque to avoid poor contact.

- Impact: Poor installation leads to intermittent connection and performance loss.

- Hidden requirement: Buyers often need extra tools or plating/cleaning to get a reliable fit.

Will these wear out faster than I expect?

- Wear pattern: Repeated heavy use commonly causes loosening and surface degradation.

- When it appears: Signs show up after repeated use, not always on first day.

- Why it matters: More upkeep than most mid-range alternatives is needed to avoid failures.

- User impact: Frequent re-tightening or replacement interrupts workflows and adds cost.

- Attempted fixes: Many buyers report temporary fixes like re-torquing or cleaning, which only delay failure.

- Fixability: Not easily serviceable in the field without spare parts on-hand.

Will this fit my machine and cables without extra work?

- Fit risk: Compatibility problems are a primary complaint for several buyers.

- Usage anchor: Issues appear during installation when studs or cable ends are slightly different size.

- Scope: Seen across multiple feedback surfaces, not just isolated cases.

- Cause: The kit expects precise cable sizes and stud hole diameter; small deviations cause poor contact.

- Impact: Mismatched parts require swapping adapters or reworking cables, adding unexpected time.

- Attempts: Buyers add shims, replace studs, or buy alternative connectors to solve fit problems.

- Hidden step: You must measure stud and cable dimensions before purchase to avoid added hassle.

- Category contrast: Typical mid-range connectors tolerate small size variance better, so this kit demands more precise prep.

Illustrative excerpts

"Connector heated and loosened mid-bead, stopped welding twice in one job." — reflects a primary pattern showing failure during use.

"Needed extra tools and experiment to get a tight fit on my cable." — reflects a secondary pattern about setup friction and hidden tools.

"Worked fine week one; started sparking after several heavy sessions." — reflects an edge-case pattern of wear after repeated high-load use.

Who should avoid this

- Frequent welders: If you run long, high-current sessions, the loose-contact risk exceeds normal tolerance.

- Mission-critical jobs: If mid-job interruptions are unacceptable, this product’s intermittent contact is too risky.

- Casual buyers without tools: If you lack measuring tools or crimp/solder gear, the hidden installation steps create extra cost.

Who this is actually good for

- Occasional hobbyists: If you weld infrequently and can stop work for adjustments, you may tolerate the fit quirks.

- Buyers on a budget: If cost matters more than long-term durability, occasional rework may be acceptable.

- Prepared tinkerers: If you keep spare parts and tools and don’t mind re-torquing, the kit can be made reliable.

Expectation vs reality

- Expectation: Reasonable for this category is a quick twist-lock that holds under motion.

- Reality: The kit can lose contact under movement or heat, causing arc interruptions and extra rework.

- Expectation: Connectors should be plug-and-play for 1/0–2/0 cables.

- Reality: You often must measure and adapt studs or cable ends before they work reliably.

Safer alternatives

- Choose connectors with proven clamp-style locking to neutralize loose-contact failures.

- Prefer options with broader fit tolerance to avoid the hidden measurement requirement.

- Buy kits that include adapters and clear torque specs to reduce installation surprises.

- Keep spares and basic tools if you accept this kit’s lower upfront price but want reliable uptime.

The bottom line

Main regret: The kit’s most common failure is intermittent contact that interrupts welding and forces rework.

Why it matters: This behavior is more disruptive than typical mid-range connectors and adds unexpected time and cost.

Verdict: Avoid this kit if you need steady, heavy-use performance; consider it only if you accept extra setup and upkeep.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.