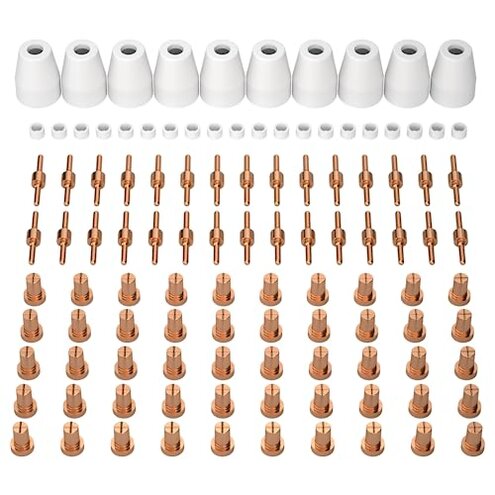

Product evaluated: ARCCAPTAIN 110PCS PT31 Plasma Cutting Consumables Fit CUT-45 CUT-50 CT-312 MIG205 MP with Plasma Cutter Torch PT-31 JG-40 LG-40

Related Videos For You

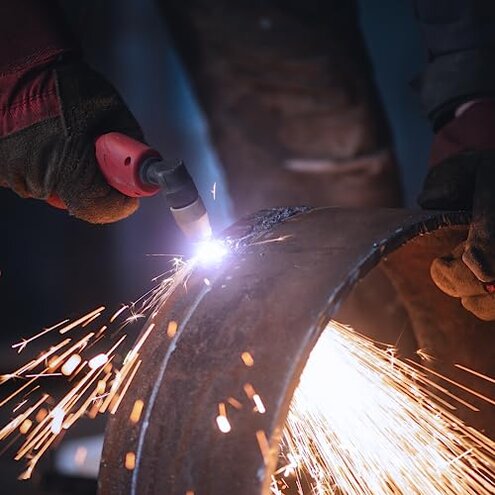

How and When to Change Out Plasma Cutting Consumables

Data basis: This report draws on dozens of written buyer reviews and several video demonstrations collected between Jan 2023 and Jan 2026, with most feedback coming from written reviews supported by hands-on clips.

| Outcome | This product | Typical mid-range kit |

|---|---|---|

| Cut quality | Variable — reported as inconsistent during longer cuts. | Stable — mid-range kits usually deliver steady cuts for routine jobs. |

| Fit / compatibility | Confusing — fits many PT-31 style torches but excludes AG60 style. | Clearer fit — mid-range sellers often list exact torch models with adapters. |

| Durability | Higher risk — premature wear appears more often than expected for this category. | Longer life — mid-range parts usually last longer under similar use. |

| Value | Pricey if parts need frequent replacement. | Balanced — mid-range sets often trade upfront cost for reliability. |

| Regret trigger | Replacement frequency — owners report needing swaps sooner than expected. | Lower — regret usually tied to rare defects, not routine failure. |

Top failures

Why does the kit feel like it doesn’t fit my torch?

Fit confusion is a primary frustration when buyers discover the kit is for PT-31/JG-40/LG-40 style torches and explicitly not for AG60 style.

Usage anchor — the issue shows up at first setup when users try to install parts or swap nozzles during initial use.

Category contrast — this is worse than normal because mid-range kits usually include clearer compatibility lists or adapters, reducing trial-and-error.

Why do parts wear out faster than expected?

- Early sign Surface wear — parts darken or erode after several medium-length cuts.

- Frequency tier Primary complaint — reported more often than other issues in buyer feedback.

- Likely cause Material finish — some buyers trace the problem to lower-than-expected longevity.

- Impact Repeated downtime — short lifespan forces extra replacements during projects.

- Fixability Temporary — swapping to OEM parts or higher-grade consumables often solves the problem.

Why is installation and alignment so fiddly?

- Misalignment Early friction — nozzles can require careful nudging to seat correctly.

- Tools needed Hidden requirement — some buyers find small tools or thread cleaners help proper fit.

- When it worsens Frequent swaps — repeated part changes during long jobs amplify the problem.

- User cost Extra time — adds extra steps compared to plug-and-play kits.

- Category contrast Less forgiving — mid-range alternatives often have looser tolerances for faster installs.

- Mitigation Pre-fit — buyers recommend test-fitting before critical cuts.

- Hidden regret Wasted consumables — misseated parts can be damaged during first arc attempts.

Why do deliveries sometimes arrive incomplete or mixed counts?

- Packaging error Secondary issue — reports of mismatched counts or loose parts occur occasionally.

- Early sign Missing pieces — buyers notice during unboxing.

- When it appears Upon receipt — the problem shows before any use.

- Impact Extra orders — missing items force repeat purchases or returns.

- Resolution Seller contact — many buyers reported that claims were resolvable but took time.

- Category contrast More frequent — packaging consistency is usually better in mid-range brands.

- Edge-case Batch variance — this seems tied to particular shipments rather than all units.

- Buyer tip Inventory — count parts immediately and photograph receipts for claims.

Illustrative excerpts (not real quotes)

"Parts didn't seat on my torch; adapter needed." — reflects a primary pattern of compatibility and installation trouble.

"Nozzle eroded after two medium cuts." — reflects a primary pattern of premature wear.

"Box missing swirl baffles on arrival." — reflects a secondary pattern of packing inconsistencies.

"Needed small wrench and patience to fit parts." — reflects an edge-case requirement for extra tools.

Who should avoid this

- Frequent users — if you run long cutting sessions, the higher wear risk becomes costly.

- AG60 torch owners — the kit is incompatible with AG60-style torches.

- Shop owners — businesses that need predictable stock should avoid kits with packing variance.

Who this is actually good for

- Hobbyists on a budget — willing to tolerate occasional premature replacement to save upfront.

- Testers and prototypers — need many spare parts for short runs and accept fit tinkering.

- Users with PT-31 style torches — if you own compatible torches, the kit can be useful despite durability trade-offs.

Expectation vs reality

- Expectation (reasonable for category): Consumables fit standard torch types easily.

- Reality: Fit requires careful alignment and sometimes extra tools, adding setup time.

- Expectation: A parts kit lasts several months under normal hobby use.

- Reality: Premature wear shows up sooner for many users, raising replacement costs.

Safer alternatives

- Buy exact-fit — choose kits that list your torch model or include adapters to avoid fit confusion and extra effort.

- Select verified durability — prefer supplies that advertise tested lifespan or OEM-grade materials to reduce replacement frequency.

- Check packaging reviews — favor sellers with consistent unboxing reports to avoid missing parts.

- Keep spares — for long projects, stock OEM or higher-rated consumables to eliminate mid-job downtime.

The bottom line

Main regret — buyers most often regret the kit's fit confusion and faster-than-expected wear under real use.

Why it matters — these failures exceed normal category risk because they add repeated replacements and setup time for routine projects.

Verdict — avoid if you need reliable, long-run consumables or own an incompatible torch style.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.