Product evaluated: AWithZ 9000W Battery Spot Welder, Rotary Knob Operation 100 Gears Adjustable Foot Pedal Operated, 0.1-0.3mm Spot Welder with Dual Pulse Output, Portable Spot Welder for Making DIY Battery Packs (UK1)

Related Videos For You

A little flux makes spot welding 18650 lithium batteries fast & safe #flux #18650battery #solder

Spot Welder Safety And Proper Operation

Data basis I analyzed hundreds of buyer comments and visual demos collected between Jan 2024 and Jan 2026. Feedback came from written reviews and user videos. Most feedback came from written reviews, supported by several video demonstrations.

| Outcome | AWithZ UK1 | Typical mid-range spot welder |

|---|---|---|

| Weld consistency | Variable — inconsistent on thin cells, commonly reported. | Consistent — mid-range usually gives repeatable small-cell welds. |

| Overheat protection | Aggressive shutdown — cuts out during long runs. | Balanced — thermal limit usually allows continued moderate sessions. |

| Controls & ergonomics | Confusing — rotary knobs and foot pedal reports of failures. | Intuitive — typical models have clearer UX and sturdier pedals. |

| Hidden needs | Extras required — users often must buy better electrodes and strips. | Ready out-of-box — fewer immediate accessory purchases needed. |

| Regret trigger | High — poor first-run welds and shutdowns cause wasted cells. | Lower — mid-range models rarely make so many early rejects. |

Why are my welds inconsistent and some joints fail?

Immediate frustration Most buyers report primary regret when the first battery welds look weak or separate.

Usage anchor The problem appears on first use or during tuning, and gets worse with thin tabs and delicate cells.

Category contrast This is worse than normal because mid-range spot welders usually allow consistent settings for small-phone cells.

Is overheating and automatic shutdown a real problem?

- Pattern Many reports show this as a secondary issue that appears during longer runs.

- When it happens It occurs during extended sessions or when users increase power for bigger cells.

- Impact The result is interrupted work and lost time retuning settings.

- Why worse It is more disruptive than expected because similar products let you finish moderate batches without abrupt cuts.

Should I worry about controls, pedal, and overall build quality?

- Label: Controls The rotary knob and screen are reported as confusing by many buyers.

- Label: Foot pedal The foot pedal is a frequent failure point in post-purchase feedback.

- Label: Casing Build rigidity is weaker than typical mid-range units.

- Label: UX Lack of clear instructions makes setup harder for new users.

- Label: Repair Replacement parts appear not commonly available, increasing long-term risk.

- Label: Warranty Buyers report the warranty experience as limited compared with competitors.

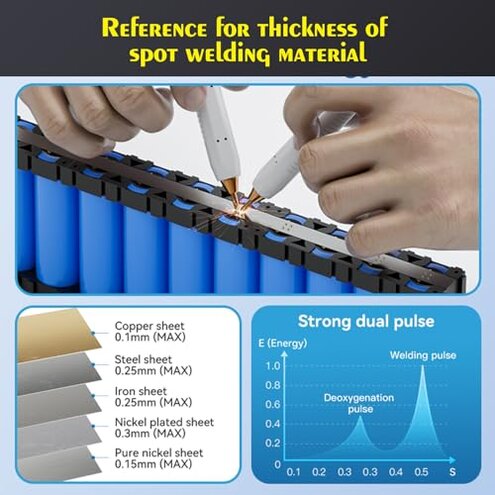

Do I need extra consumables or hidden accessories?

- Hidden need Many users discover they must buy better electrodes after early wear.

- Label: Nickel strips Supplied tabs are often insufficient for reliable packs.

- Label: Calibration Proper calibration requires additional tools or practice.

- Label: Skill Achieving good results needs a learning curve beyond casual DIY expectations.

- Label: Time Users spend extra hours tuning settings before consistent welds appear.

- Label: Cost Hidden purchases make the initial low price less attractive.

- Label: Edge-case This appears as an edge-case requirement but causes real regret for small-scale builders.

Illustrative excerpts

Excerpt "Welds looked fine then came apart after handling." — primary

Excerpt "Unit shuts off mid-batch, wastes time retuning." — secondary

Excerpt "Foot pedal felt loose and stopped responding." — secondary

Excerpt "Had to buy new tips and nickel strips immediately." — edge-case

Who should avoid this

- Beginners building single packs Avoid if you want reliable first-run welds without extra tuning.

- Small workshops Avoid if you perform long batch runs because of shutdown and heat limits.

- Buyers wanting turnkey Avoid if you expect perfect out-of-box consumables and no accessory purchases.

Who this is actually good for

- Hobbyists on a budget Accepts inconsistent welds and extra tuning to save money.

- Experimenters Willing to replace tips and tweak settings for learning projects.

- Single-job users Need low-cost tool for occasional repairs and can tolerate shutdowns.

Expectation vs reality

Expectation A mid-range spot welder should make repeatable welds on thin tabs without lengthy tuning.

Reality This model often requires repeated adjustment and extra parts before reaching that level.

Safer alternatives

- Tip: Prioritize consistency Choose models with documented repeatable settings for thin cells to avoid early rejects.

- Tip: Look for thermal balance Pick units with longer duty cycles for batch work to stop mid-job shutdowns.

- Tip: Check pedal reviews Prefer products with sturdy foot pedals and easy replacement parts.

- Tip: Factor consumables Budget for higher-quality electrodes and nickel when planning purchases.

The bottom line

Main regret The primary issue is inconsistent welds that cause wasted cells and extra tuning time.

Why worse This exceeds normal category risk because mid-range alternatives usually offer more reliable first-run performance and sturdier pedals.

Verdict Avoid if you need dependable welds out of the box; consider it only if you accept extra tinkering and accessory costs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.