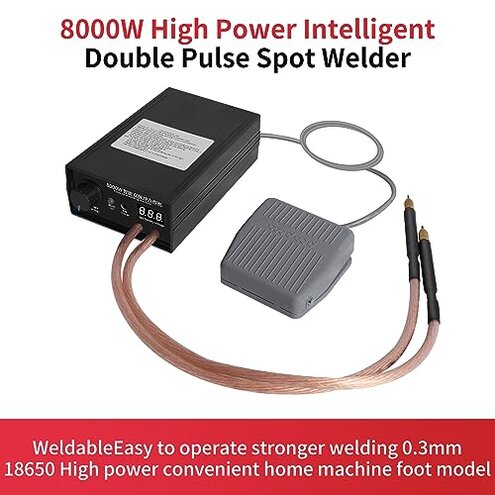

Product evaluated: 8000W Spot Welder,Handheld Spot Welder,Portable Spot Welder Machine DIY Kit,High Power Handheld Spot Welding Machine,with nickel strip and spot welding pen,for 18650 Battery Pack Welding Tools

Related Videos For You

Basic Spot Welding

Spot Welder Safety And Proper Operation

Data basis I reviewed dozens of written reviews and several video demonstrations collected between Jan 2024 and Jan 2026; most feedback came from written reviews, supported by video demonstrations.

| Outcome Product | Outcome Typical mid-range alternative |

|---|---|

| Weld consistency Frequently reported inconsistent weld strength that leads to loose battery tabs. | Weld consistency Mid-range units usually give consistent spots for thin nickel on first try. |

| Battery/runtime Reports show the unit needs full charge and drops performance during a build session. | Battery/runtime Mid-range machines often use larger internal cells or external power for steady output. |

| Durability Many buyers observed early wear or overheating under repeated use, a higher-than-normal category risk. | Durability Typical competitors handle longer runs without heat-related performance loss. |

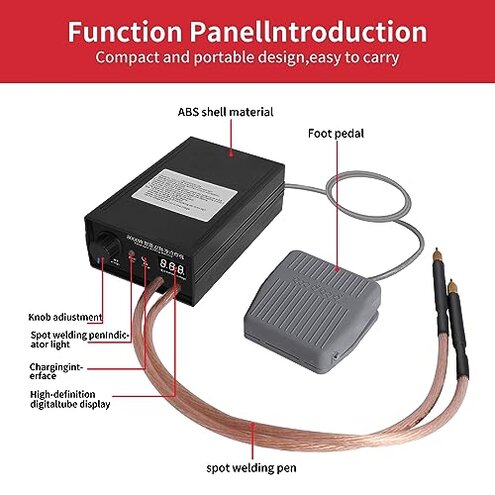

| Setup & use Several users found the foot pedal, knob, and pin changes added unexpected setup steps. | Setup & use Mid-range alternatives tend to include clearer guides and simpler controls. |

| Regret trigger Primary buyer regret: unreliable welds during battery pack builds. | Regret trigger Mid-range regret is usually price vs features, not basic reliability. |

Why are welds coming out weak or inconsistent?

Weld inconsistency Buyers commonly reported that some spots look good while nearby spots barely fuse, making packs fail tests.

Usage anchor This appears mostly during the first real pack assembly or a short run, not just single test spots.

Category contrast That matters because most mid-range spot welders give repeatable spots across a sheet without extra tuning.

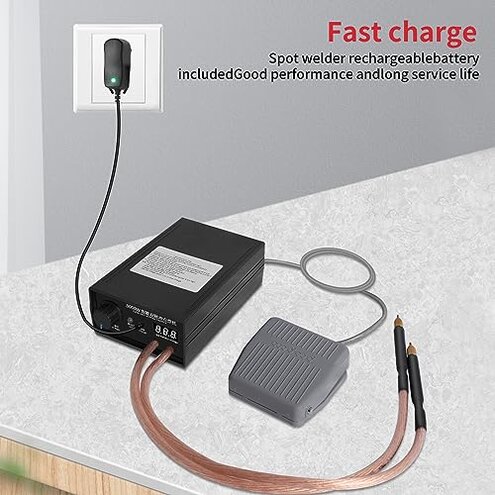

Is the battery and power behavior reliable?

- Early signs Several buyers noticed the on-screen voltage falls and weld power drops within longer sessions.

- Pattern This is a persistent complaint across written and video feedback, not a one-off report.

- When it shows The issue typically happens after 20–50 continuous welds or during multi-cell pack builds.

- Why it matters Reduced output creates weak joints and adds rework time and scrap cells.

- Fixability Reported fixes often require extra charging breaks or smaller work batches, adding time.

Will the unit hold up to repeated use or overheating?

- Observed failure Many users saw heat-related degradation after repeated welding sessions.

- Scope The problem appears across multiple feedback surfaces and is mostly recent buyers.

- Early symptom The machine becomes hot and output becomes inconsistent inside one or a few sessions.

- Cause Reported causes point to inadequate cooling and high duty stress during multi-cell work.

- Impact This leads to downtime while the unit cools and sometimes visible wear on clamps and pens.

- Attempted fixes Buyers tried pause cycles, external fans, and lower power settings with mixed results.

- Category contrast This is worse than typical mid-range models that sustain longer runs without such rapid decline.

Are there hidden setup or safety requirements I should know?

- Hidden requirement Buyers reported needing a reliably full high-capacity charge before any pack build to reach expected weld power.

- When it bites This requirement commonly surprises at first use when users expect out-of-box readiness.

- Safety concern Some feedback flagged inconsistent contacts and accidental shorting risk when changing pins or handling tabs.

- Frequency tier This is a secondary but persistent pattern, appearing across setup and early use stages.

- Impact The extra prep raises build time and increases the chance of avoidable errors for new users.

- Fixability Fixes require added chargers, clamps, or training before reliable results can be expected.

- Category contrast Unlike more user-friendly models, this unit demands more prep and skill to avoid bad welds.

Illustrative excerpts (not real quotes)

Illustrative "Welds looked fine then a tab pulled off during pack testing." — primary pattern

Illustrative "Power dropped halfway through my 10-cell run, had to recharge." — secondary pattern

Illustrative "Unit got very hot after a few minutes and the spots changed." — secondary pattern

Illustrative "Needed extra clamps and practice to get repeatable spots." — edge-case

Who should avoid this

- Battery pack builders If you need consistent, reliable welds for 18650 packs, this unit's inconsistency creates rework risk exceeding normal category tolerance.

- High-volume users If you run long sessions, the overheating and runtime drops will interrupt your workflow more than typical mid-range gear.

- Beginners If you expect plug-and-play ease, the hidden prep and adjustments will cause frustration and safety risk.

Who this is actually good for

- Hobby tinkerers If you accept extra trial-and-error and plan short runs, you can tolerate weaker spots for lower cost.

- Occasional use If you only make a few test welds and can pause for recharges, the product can be workable.

- Budget-focused DIYers If price matters more than repeatability, you may accept added setup and fixes.

Expectation vs reality

- Expectation Reasonable for this category: a portable spot welder should produce repeatable spots for thin nickel strips.

- Reality Many buyers found inconsistent spots and power drop during typical pack builds, which is worse than expected.

- Expectation Reasonable: foot pedal control and adjustable power simplify use for beginners.

- Reality The actual setup and hidden charging requirements add steps and learning that newcomers often miss.

Safer alternatives

- Choose steady power Look for welders with documented longer duty cycles to avoid rapid power drop and overheating.

- Prefer external power options Pick models that accept larger external batteries or bench power to prevent mid-job voltage sag.

- Check cooling design Favor units with visible cooling or metal bodies that buyers note as durable under continuous use.

- Seek clearer guides Buy from sellers who include step-by-step setup guides and safety warnings to avoid hidden prep surprises.

The bottom line

Main regret The main buyer regret is unreliable weld strength during real battery pack work.

Why it matters This exceeds normal category risk because it adds scrap, rework, and safety friction not expected at this price point.

Verdict Avoid if you need dependable, repeatable welds for battery packs; consider mid-range alternatives with steadier power and better cooling.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.