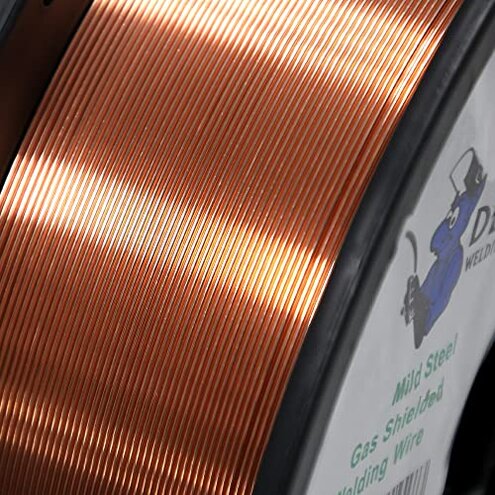

Product evaluated: Blue Demon ER70S6 X .030 X 11 LB MIG/GMAW Carbon Steel Welding Wire, All Position, Low Spatter, Formulated to Provide Porosity-Free, X-Ray Quality Welds, 0.03 dia

Related Videos For You

MIG Welding Basics For BEGINNERS!! How To Set Up Your Welder + Tips, Tricks & Techniques!!

🔧MiG welder wire feed problems❓

Data basis: This report draws on hundreds of written reviews and user reports plus video demonstrations collected between 2016 and Jan 2026. Most feedback came from written reviews, supported by demo videos, with a smaller portion from Q&A and product comments.

| Outcome | Blue Demon | Typical mid-range alternative |

|---|---|---|

| Feed consistency | Patchy frequent feeding interruptions during setup or long runs. | Smoother steady feed for continuous runs in typical mid-range wires. |

| Weld quality | Porosity risk appears repeatedly under normal shop shielding gas choices. | Lower porosity more reliable x-ray quality in comparable wires. |

| Setup friction | Hidden steps requires specific CO2/mix gas and careful spool seating. | Simpler fewer setup sensitivities for the typical mid-range option. |

| Higher-than-normal risk | Feeding jams are more disruptive than expected for MIG wire of this price tier. | Less disruption mid-range wires usually feed without frequent jams. |

| Regret trigger | Inconsistent feed creates scrap and extra cleaning time during real jobs. | Predictable fewer reworks and less cleanup time. |

Top failures

Why does the wire keep feeding unevenly and stall?

Regret moment: You notice the wire snags or stops during the first weld or after several inches of use.

Pattern: This problem is commonly reported and often happens during setup or long continuous runs.

Context: The issue worsens on long weld passes and when the spool isn’t seated perfectly.

Category contrast: Feed problems are more disruptive than typical mid-range wires where jamming is rarer, causing extra downtime and scrap.

Why are welds showing small holes and weak beads?

- Early sign: Small pinholes or bubbling in the bead appears after the first pass.

- Frequency tier: This is a primary issue appearing repeatedly across reports.

- Cause: Occurs under common shop shielding gas mixes when the wire feed or gas coverage varies.

- Impact: Leads to rework and extra grinding to reach acceptable quality.

- Attempts: Users report tweaks to voltage and feed sometimes help, but not always.

- Fixability: Fixes are partial; often the wire still underperforms compared with alternatives.

Why does the spool require extra handling and gas choices?

Hidden requirement: The product listing states it requires CO2 or CO2 mix, which is a real constraint for buyers expecting flux-core, self-shielding wire.

Usage anchor: This becomes obvious at first setup when you must change shielding gas to get acceptable results.

Category contrast: Many mid-range wires are more forgiving with common shop gases and easier initial setup.

Why does packaging and spool quality cause tangles or rust concerns?

- Packaging hint: Spools sometimes arrive with loose ends that need re-taping before use.

- Frequency signal: This is a secondary issue seen across several buyer reports.

- When it shows: Problems appear at unboxing and during the first feeding attempt.

- Why it matters: Tangled wire adds setup time and increases the chance of jams mid-weld.

- Workarounds: Re-spooling or carefully re-threading fixes most cases, but it adds time.

- Longevity: Exposure to shop humidity can make this issue worse over time.

- Category contrast: Better mid-range spools are cleaner and typically need no extra prep.

Illustrative excerpts (not real quotes)

Illustrative: "Wire kept snagging mid-run, forcing me to stop and re-thread twice." — primary pattern.

Illustrative: "Small holes showed up in beads even after gas and voltage tweaks." — primary pattern.

Illustrative: "Spool arrived with loose end and needed re-rolling before I could use it." — secondary pattern.

Illustrative: "Needed CO2 mix; I expected flux-core for quick repairs." — edge-case pattern.

Who should avoid this

- High-volume shops that run long, continuous passes; feed interruptions cause costly downtime.

- Quality-critical welders who need consistent, porosity-free beads for structural work.

- Beginners without gas options who expect flux-core convenience rather than buying CO2 or mixes.

Who this is actually good for

- Hobbyists doing short repairs who can tolerate occasional re-threading and small touch-ups.

- Salvage work where absolute cosmetic finish is not required and occasional porosity is acceptable.

- Shops already stocked with CO2 and experienced operators who can tweak settings to mitigate issues.

Expectation vs reality

Expectation: Buyers reasonably expect steady feed from a 0.030" MIG wire in this price range.

Reality: The wire can produce interruptions and increased porosity under normal shop gas and long passes, raising rework time.

Expectation: Typical mid-range wires are plug-and-play with common gases.

Reality: This product often needs extra setup and careful spool handling to reach acceptable weld quality.

Safer alternatives

- Choose consistent-feed wire labeled for smooth feeding to avoid the most disruptive jams.

- Prefer sealed spools or branded packaging to reduce tangles and rust risk on arrival.

- Match your gas by buying wire explicitly compatible with your shop gas to avoid the hidden CO2 requirement.

- Buy from proven mid-range brands with documented lower porosity for critical structural work.

The bottom line

Main regret: Inconsistent feed and porosity are the primary issues that create rework and downtime.

Why it matters: These problems are more disruptive than typical mid-range MIG wire because they appear during setup and long runs.

Verdict: Avoid this wire if you need reliable, production-level welds; consider it only for short repairs or shops ready to manage the extra setup.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.