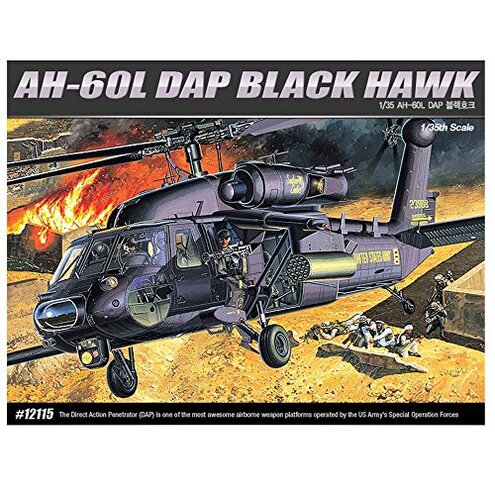

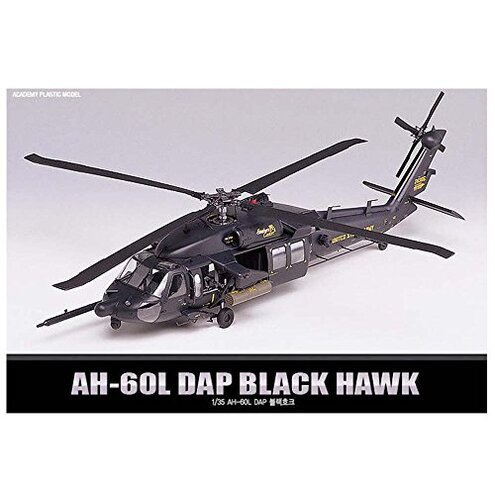

Product evaluated: Academy 12115 AH-60L DAP BLACK HAWK Helicopter Plastic Model Kit

Related Videos For You

BUILDING ICM CH 54 TARHE SCALE HELICOPTER MODEL KIT - WITH FULL BUILD PHASES

19 Tips and Tricks for Scale Modelers

Data basis I reviewed dozens of buyer reports and demonstration videos collected between 2018 and 2025, with most feedback coming from written reviews supported by video demonstrations. Source mix shows a qualitative skew: written reviews were primary, with video walkthroughs confirming assembly and fit problems.

| Outcome | Academy AH-60L | Typical mid-range kit |

|---|---|---|

| Assembly difficulty | High — parts often need trimming or sanding to fit during build. | Moderate — some cleanup typical, fewer fit surprises for this category. |

| Missing or warped parts | Above-normal risk — missing/warped pieces appear repeatedly and break the build. | Low — mid-range kits rarely have systemic missing-piece patterns. |

| Instructions clarity | Poor — steps can be vague and assume advanced skills. | Clearer — comparable kits use clearer diagrams and part numbering. |

| Final fit & finish | Inconsistent — seams and gaps often need putty and sanding to hide. | More consistent — typical kits produce better alignment with basic skills. |

| Regret trigger | High — build time and extra supplies needed often exceed buyer expectations. | Lower — fewer unexpected tools or time required for a comparable result. |

Top failures

Why do parts not fit together cleanly?

Regret moment is when you try to join major fuselage pieces and see large gaps or misaligned panels during first dry-fit. Pattern is commonly reported and often appears on initial assembly steps.

Usage anchor the issue shows up on first use when following the instructions and worsens if you rush gluing without test-fits. Category contrast this is worse than typical mid-range kits that usually need only light sanding.

Are small, fragile pieces frequently damaged or missing?

- Early sign small antennae or launch tubes are bent or off sprue cleanly, commonly reported in written feedback.

- Frequency tier this is a secondary issue but appears repeatedly enough to affect display quality.

- Cause delicate sprue attachment and thin parts increase breakage during removal.

- Impact broken parts force improvisation or aftermarket replacements, adding time and cost.

- Attempted fixes modellers report gluing, reshaping, or cannibalizing other kits where possible.

Will the instructions and part mapping slow me down?

- Pattern many builders find the manual vague and rely on photographic video demos for clarification.

- When confusion appears during mid-build subassemblies, it commonly causes rework and wasted glue time.

- Why worse than expected because comparable kits include clearer exploded views and part codes.

- Hidden requirement you will often need intermediate modelling skills or reference photos to interpret steps.

- Fixability community-sourced guides and extra reference photos help but add prep time.

- Scope mostly affects first-time builders and those used to clearer instruction sets.

- Outcome plan for extra dry-fit time and a possible re-do of subassemblies.

Does the kit demand more tools and finishing work than advertised?

- Core problem achieving a clean final model commonly requires putty, sanding, and aftermarket decals for a neat finish.

- Early sign visible mold lines and ejector marks show up as soon as you remove parts from sprues.

- Frequency this is among the most common complaints across feedback types and persists through build completion.

- Impact adds extra cost and time: expect more prep than most mid-range kits demand.

- Attempts some buyers purchased filler and fine-grit sandpaper mid-build to salvage panels.

- Hidden cost you may need paints, putty, and better tools to reach satisfactory display quality.

- Fixability results improve only if you have intermediate skills or willingness to spend on extras.

Illustrative excerpts (not real quotes)

Illustrative: "Doors didn’t line up; needed sanding and putty before glue." — Primary pattern.

Illustrative: "Tiny antenna snapped during sprue removal, ruined the look." — Secondary pattern.

Illustrative: "Manual skipped a step; watched a video to finish correctly." — Primary pattern.

Who should avoid this

- Beginners who expect plug-and-play builds without extra tools or skills.

- Time-limited buyers who cannot add sanding, filling, or rework time into the project.

- Buyers on a tight budget unwilling to purchase putty, fine sandpaper, or replacement small parts.

- Display-first collectors who expect near-perfect out-of-box alignment at this price point.

Who this is actually good for

- Experienced modelers willing to tolerate extra cleanup and who enjoy customizing and finishing work.

- Hobbyists with tools who already own putty, sanding sticks, and aftermarket decals to fix fit and finish.

- Budget modders who want a detailed shape and can accept extra time to reach a good result.

- Reference builders who use videos and photos and don’t rely solely on the instruction sheet.

Expectation vs reality

Expectation (reasonable) mid-range military kits usually need light trimming and basic painting to look good. Reality this kit often requires extensive sanding, putty, and extra parts work, exceeding that reasonable baseline.

Expectation assembly instructions will guide subassemblies clearly. Reality the manual is sometimes vague and forces builders to search video demos or community advice.

Safer alternatives

- Choose kits with clearer manuals — prefer brands known for step-by-step exploded views to avoid instruction confusion.

- Pick kits with stronger part engineering — look for reviews highlighting good snap-fit alignment to prevent gaps.

- Buy from sellers offering replacements — ensure vendor support for missing or warped parts before purchase.

- Stock basic finishing tools — get putty, fine sandpaper, and precision cutters to neutralize fit and finish problems.

The bottom line

Main trigger the most common regret is poor part fit and extra finishing needs that inflate time and cost. Severity these problems are worse than typical mid-range kits because they are persistent and visible in early assembly steps. Verdict avoid this kit if you’re inexperienced, short on time, or unwilling to buy extra tools.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.