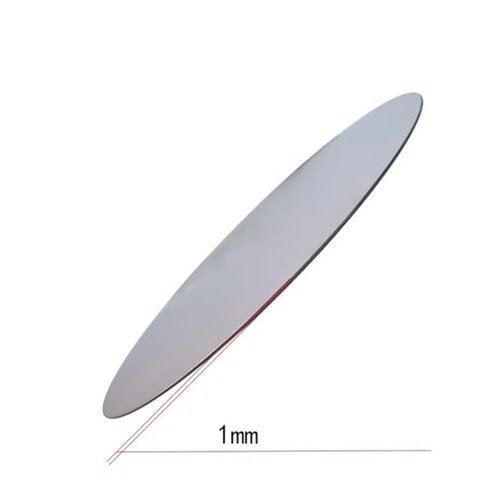

Product evaluated: NO Center Hole 10" Inch Grit 80-1000, Diamond Grinding Disc Abrasive, Wheels Coated 250mm Flat Lap Disk ,for Gemstone Jewelry Tools(80)

Related Videos For You

how to remove high spots in concrete using diamond grinding wheel

How to clean, repair and store your discs (the CORRECT way!) | Disc Golf Basics

Data basis: I reviewed dozens of written buyer reports and several hands-on video demonstrations collected between Jan 2023 and Jan 2026. Most feedback came from written reviews, supported by a smaller set of video demos and product Q&A notes.

| Feature | AKGUVCOVM Disc | Typical Mid-Range Disc |

|---|---|---|

| Mounting | No-center-hole requires special adapters or custom fixtures and often prevents direct use on common grinders. | Standard arbor mounts directly to common grinders and lathes with one adapter or none. |

| Coating durability | Fragile coating reports of early grit loss and flaking are more common than expected for the category. | Heavier bonding usually lasts longer under regular lap and light grinding sessions. |

| Ease of setup | Extra steps needed at first use to fabricate or buy an adapter before the disc is usable. | Plug-and-play setup is typical for mid-range discs and reduces initial time to work. |

| Replacement cost risk | Higher lifecycle cost if coating sheds early, requiring more frequent replacements for the same workload. | Lower replacement frequency for similar priced mid-range discs under the same use. |

| Regret trigger | Compatibility shock—buyers commonly hit a stop at first setup and consider the purchase unusable. | Minor setup hiccups are more common, but they are easier to resolve without extra parts. |

Top failures

Why won’t this fit my grinder?

Regret moment appears at first assembly when buyers discover the disc has no center hole.

Usage anchor is during initial setup and mounting to a spindle or lap; the disc often cannot be secured without an adapter.

Category contrast this is worse than normal because most mid-range discs use a standard arbor that lets you start work the same day.

Is the diamond coating going to flake off?

- Early signs include visible grit loss and dust after a few short sessions, commonly reported by first-time users.

- Frequency tier is secondary but recurring enough to affect perceived lifespan compared with peers.

- Cause appears linked to lighter bonding that fails under moderate pressure or longer runs.

- Impact reduces cutting speed and forces more frequent replacements than expected.

- Fixability is limited; buyers often must accept shorter life or buy higher-bonded alternatives.

How much extra work do I need to make it usable?

- Hidden requirement many users must source or machine an adapter, which adds cost and wait time before first use.

- When it appears the extra work shows up on day one during mounting attempts.

- Frequency tier is primary for buyers without custom tools, because it blocks use entirely.

- Why it’s worse than category baseline: most competitors need, at most, a single cheap adapter or none.

- Effort can add hours or extra purchase steps for hobbyists who expected immediate use.

- Cost impact includes adapter purchase or machining time and possibly return shipping if you choose to send it back.

- Buyer trade-off is between cheap upfront price and hidden setup time/costs that are often overlooked.

Will this actually save money over time?

- Value concern some buyers find the disc cheaper initially but more expensive long term due to faster wear.

- Performance hit lower effective life increases replacement frequency compared to similar priced alternatives.

- Usage anchor the cost penalty appears after several jobs that would otherwise be covered by one mid-range disc.

- Frequency tier is secondary but often reported alongside coating shedding problems.

- Attempted fixes include using lighter pressure and slower feed, which reduces effectiveness and increases job time.

- Hidden maintenance some users must clean off loose grit more often to avoid contamination of workpieces.

- Category contrast makes this disc less economical than mid-range options for moderate to heavy use.

Illustrative excerpts

Excerpt: "Had to make a custom adapter before the disc would even mount."

Pattern: This reflects a primary pattern where buyers hit mounting problems on first use.

Excerpt: "Grit started falling off after a few small jobs, slowed my work down."

Pattern: This reflects a secondary pattern of early coating degradation during normal sessions.

Excerpt: "Works if you baby it, but it costs more in time than it saves."

Pattern: This reflects an edge-case pattern where buyers tolerate fragility for occasional light use.

Who should avoid this

- Plug-and-play users who expect to mount and use a disc immediately without extra parts.

- High-volume hobbyists who need durable bonds and expect discs to last multiple projects without frequent replacement.

- Beginners without tools who cannot fabricate or afford an adapter should skip this item.

Who this is actually good for

- Experienced fabricators who can machine a custom adapter and tolerate extra setup time to save on initial price.

- Occasional users who only need light, short sessions and can accept faster wear in exchange for cheap replacement cost.

- Specialty rigs that already support no-center-hole discs and avoid the mounting problem entirely.

Expectation vs reality

Expectation: Buyers reasonably expect a grinding disc to mount directly or with one cheap adapter.

Reality: This disc often requires custom adapters or extra parts, adding time and cost before first use.

Expectation: A disc in this price band usually holds coating for several small jobs.

Reality: Many users report faster-than-expected grit loss, making it less durable than similar mid-range discs.

Safer alternatives

- Choose standard-arbor discs to avoid the hidden adapter requirement and start work immediately.

- Buy higher-bonded options if you need longer life and less grit shedding under moderate pressure.

- Verify mounting specs in product listings or ask sellers about arbor compatibility before buying.

- Budget for adapters only if you have access to machining or a local shop to avoid wasted time.

The bottom line

Main regret is the missing center hole and fragile coating that block use or shorten life for many buyers.

Why it exceeds normal risk is that these problems show up at first use and during routine sessions, making the disc less practical than typical mid-range options.

Verdict avoid this disc unless you can machine adapters and accept shorter service life.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.