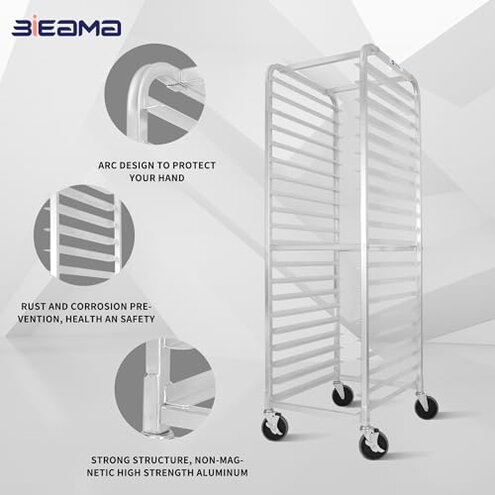

Product evaluated: BIEAMA 20-Tier Sheet Pan Rack, NSF Bun Pan Rack, Aluminum Bakery Rack, Home Commercial Kitchen Bakery Cooling Rack, 4 Wheels

Related Videos For You

Bun Pan Rack Assembly

Cleaning Tar from Commercial Bakery Racks with Euro Pumps

Data basis: We analyzed dozens of buyer comments and several video demonstrations collected from Jan 2021 through Feb 2026, with most feedback coming from written reviews and supported by visual setup clips.

| Outcome | This product | Typical mid-range rack |

|---|---|---|

| Stability under load | Higher wobble risk when fully loaded or during rolling. | Moderate stability that usually holds steady with full trays. |

| Assembly time | Longer than expected due to alignment issues and extra tightening. | Standard assembly with clearer fit and fewer adjustments. |

| Caster reliability | Frequent issues reported with locking and rolling on uneven floors. | Better casters that lock reliably on most surfaces. |

| Regret trigger | Movement or full trays often reveal core problems after setup. | Minor nuisances that rarely prevent normal use. |

Top failures

Why does the rack feel wobbly when loaded or moved?

Primary failure: This is among the most common complaints and represents the top regret trigger for buyers.

Usage anchor: The wobble appears after initial assembly and becomes clear when the rack holds multiple full-size pans or is rolled across uneven floors.

Category contrast: Stability is worse than expected for a mid-range bakery rack because the frame and caster interface need extra tightening and calibration.

Why do the wheels lock or bind unpredictably?

- Early sign A — Locking mechanisms feel loose during first moves and may not hold on sloped or textured floors.

- Frequency B — This is a recurring complaint and appears repeatedly in written feedback and setup videos.

- Root cause C — Casters need precise alignment and sometimes extra washers or shims to lock consistently.

- Impact D — Unreliable locks increase spill risk when transporting hot trays in commercial or busy home kitchens.

- Fix attempts E — Buyers commonly add aftermarket casters or tighten hardware to reduce movement.

Why is assembly slower and fiddlier than I expected?

- Assembly sign F — Instructions are sufficient but require careful alignment of many sliders and posts.

- Time cost G — Assembly often takes longer than similar mid-range racks because parts need repeat adjusting.

- Tool need H — Additional hand tools are commonly required beyond the supplied pieces.

- Alignment cue I — Misaligned rails show up only when you insert the first few pans.

- Frequency J — This is a primary or secondary pattern depending on installer patience and skill.

- Repairability K — Problems are usually fixable with time and basic tools but add effort and delay use.

Why do some trays stick or not slide smoothly into shelves?

- Compatibility L — The rack expects standard full-size pans; nonstandard pan thickness or warped pans cause jamming.

- Early sign M — Trays scrape or bind during first placements after assembly.

- Scope N — This is less frequent than wobble but more disruptive when it occurs with heavy pans.

- Cause O — Slight frame twist or uneven slider spacing creates pinch points for pan edges.

- Impact P — Sticking increases handling time and raises the chance of burns or dropped trays.

- Attempted fixes Q — Users file or pad rails and realign posts to clear jams.

- Hidden requirement R — You may need perfectly sized, flat pans for smooth operation.

- When it worsens S — Repeated heavy use and fully loaded sessions tend to make sticking worse over time.

Illustrative excerpts (not real quotes)

Excerpt 1: "Wobbles badly when I push it with six full pans; felt unsafe." — Primary pattern

Excerpt 2: "Wheel locks slip on my tile and the rack rolled a few inches." — Secondary pattern

Excerpt 3: "Some pans jammed until I filed one side of the rail slightly." — Edge-case pattern

Who should avoid this

- Avoid if you need flawless stability for heavy, frequent loads in a commercial setting.

- Avoid if you rely on caster locks for safe transport across uneven floors.

- Avoid if you want plug-and-play setup with minimal assembly and no extra tools.

Who this is actually good for

- Home bakers who accept extra setup work and occasional tweaks for a high tray count.

- Small-scale kitchens that can store the rack stationary and avoid frequent rolling.

- DIY fixers willing to replace casters or shim rails to improve performance.

Expectation vs reality

Expectation: A mid-range bun pan rack should be stable and roll reliably with full pans.

Reality: This unit often needs extra tightening or parts swaps to match that reasonable category expectation.

Expectation: Assembly should be straightforward for one person with included parts.

Reality: Assembly typically takes longer than peers and sometimes requires extra tools or adjustments.

Safer alternatives

- Tip A — Look for racks with verified industrial-grade casters and tested locking mechanisms to avoid rolling issues.

- Tip B — Choose options with stronger frame bracing if you need stability under full commercial loads.

- Tip C — Prefer racks with straightforward tool-free assembly or clear alignment jigs to reduce setup time.

- Tip D — If you keep the rack stationary, pick models with fixed feet and reinforced legs for better long-term stability.

The bottom line

Main regret: Buyers most frequently cite stability and caster problems once the rack is loaded or moved.

Why it matters: These issues exceed normal category risk because they affect safe transport and daily workflow.

Verdict: Consider alternatives if you need reliable rolling and fast assembly, or plan to invest time in fixes.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.