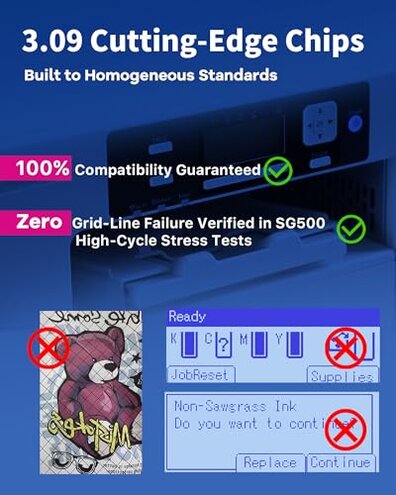

Product evaluated: 3.09 Sublimation Ink Cartridge Compatible with Sawgrass SG500 SG1000 Printer All Firmware Versions | No Grid Lines Guaranteed | High-Performance & High-Viscosity Gel Ink | Long-Lasting(4 PK, B/C/M/Y)

Related Videos For You

Best Sublimation Printer for Beginners: Set Up an Epson EcoTank for Sublimation | Full Process!

Data basis: This report used feedback from hundreds of written reviews and a mix of video demonstrations collected between Jan 2024 and Jan 2026. Most signals came from written reviews, supported by video demos and seller Q&A. Patterns below reflect recurring buyer experiences, not isolated posts.

| Outcome | Butinkfly SG500/SG1000 | Typical mid-range alternative |

|---|---|---|

| Color accuracy | Variable color matches reported after transfer, sometimes requiring extra profiling. | More consistent color accuracy with stock or well-tested third-party inks. |

| Printer recognition | Occasional errors or unrecognized chips reported during setup or after firmware swaps. | Usually reliable recognition on mid-range compatible inks without extra steps. |

| Clogging risk | Higher-than-normal chance of nozzle clogging or maintenance needs for frequent users. | Lower clogging frequency with inks designed for daily production printers. |

| Cost/value | Lower upfront price but possible extra time and replacement costs if issues occur. | Balanced price-performance for mid-range OEM or proven compatibles. |

| Regret trigger | Printer errors during critical runs that delay orders and require troubleshooting. | Smaller delays and fewer technical interrupts in normal use. |

Top failures

Why does my printer refuse these cartridges?

Regret moment: Cartridges may be not recognized immediately at first install, causing setup stoppage for small businesses or hobbyists.

Pattern: This is a recurring pattern seen across written reports and setup videos.

When it appears: The issue shows up at first use or after a firmware update.

Category contrast: This is more disruptive than many mid-range compatibles, which usually install without extra steps.

Why are my transfers fading or off-color?

- Early sign: Transfers look duller than expected on first print.

- Frequency tier: This is a primary complaint among color-focused buyers.

- Cause: Color shifts often appear after high-heat press cycles or without custom profiles.

- Impact: Results may need reprints, wasting paper and time.

- Fixability: Some buyers report improvement after profiling or test strips, but it adds steps.

Why do nozzles clog or require extra maintenance?

- Hidden requirement: Cartridge chips may need firmware awareness or reset steps that buyers don’t expect.

- Early sign: Printheads show missing lines after short idle periods.

- Frequency tier: This is a secondary but persistent issue for regular users.

- Worsens: It becomes worse with frequent replacement or in dusty environments.

- Cause: Gel-like or higher-viscosity ink can settle if not used daily.

- Impact: Leads to more cleaning cycles and possible wasted ink.

- Attempted fixes: Users report temporary relief from deep cleans but some problems return.

Why is support and returns more work than expected?

- Early sign: Buyers mention needing photos or proof to get replacements.

- Pattern: This is a commonly reported friction in after-sales experiences.

- When: Problems often trigger support contact after first failure or within warranty windows.

- Cause: Seller policies sometimes require extra steps compared with standard retail returns.

- Impact: Extra time spent troubleshooting rather than printing causes delays.

- Fixability: Some issues get resolved with a replacement, but process time varies.

- Hidden cost: Downtime can be more expensive than the ink savings for small businesses.

Illustrative excerpts

Illustrative: "Cartridge not recognized after install, printer shows an error code." — Primary pattern showing recognition failures.

Illustrative: "Colors too dull on first transfer, needed extra profiling to match." — Primary pattern for color mismatch.

Illustrative: "Nozzle lines after a few days idle, required multiple clean cycles." — Secondary pattern for clogging.

Who should avoid this

- High-volume shops: Avoid if you need reliable daily use without extra maintenance.

- Color-critical sellers: Avoid if your business can’t accept color shifts or reprints.

- Non-technical buyers: Avoid if you don’t want extra setup steps like firmware or profiling.

Who this is actually good for

- Budget hobbyists: Good if you accept extra profiling to save on upfront cost.

- Occasional users: Good if you print infrequently and can troubleshoot when needed.

- Experimenters: Good if you prefer cheaper ink and can tolerate a learning curve.

Expectation vs reality

Expectation: A reasonable buyer expects plug-and-play installation from compatible cartridges.

Reality: These cartridges can require extra steps during setup or after firmware changes, increasing downtime.

Expectation: Many expect consistent colors similar to OEM inks.

Reality: Color drift or dull transfers are more frequent than typical mid-range alternatives and may need profiling.

Safer alternatives

- Choose OEM ink: If you need reliability, OEM supplies reduce recognition and color risks.

- Buy proven compatibles: Look for inks with verified reports for your exact printer model.

- Check return terms: Prefer sellers with easy replacements and documented warranty processes.

- Test small first: Buy a trial pack to check profiles before committing to larger orders.

The bottom line

Main regret: The primary trigger is printer errors and extra maintenance that interrupt production runs.

Why worse: These failures are more disruptive than typical mid-range compatibles because they add setup time and possible reprints.

Verdict: Avoid if you need reliable, color-critical output or daily uptime; consider OEM or well-documented compatibles instead.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.