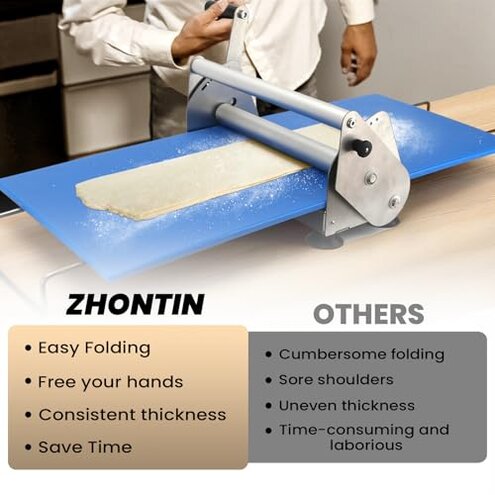

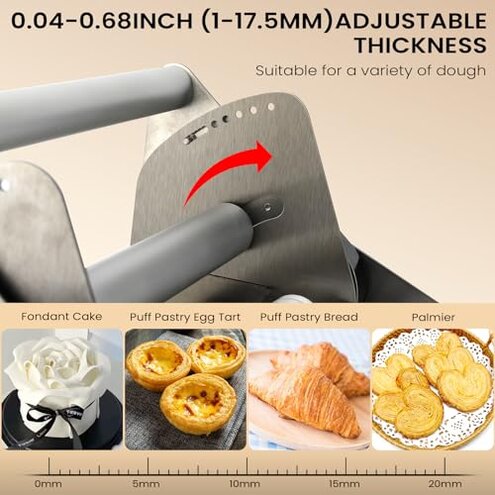

Product evaluated: Compact Dough Sheeter (12") with 2 Sheeter Board. Manual Dough Sheeter Machine with Adjustable Thickness Settings for Making Fudge Crust, Pizza Dough, Puff Pastry Dough

Related Videos For You

Manual Dough Sheeter RS201; How to use

How to Clean the Somerset Industries CDR-500 Dough Sheeter

Data basis: analysis of dozens of user reviews and demonstration videos collected between June 2024 and January 2026, with most feedback from written reviews and supported by video demonstrations and Q&A notes.

| Outcome | Product | Typical Mid‑Range |

|---|---|---|

| Thickness accuracy | Inconsistent under load; settings often slip during longer rolling. | More stable settings under similar use in mid‑range alternatives. |

| Durability | Fragile parts reported after repeated use or heavy dough. | Rugged metal or reinforced designs last longer in category. |

| Cleanup | Extra steps needed when parts jam or retain dough. | Cleaner surfaces and simpler disassembly are common in rivals. |

| Cost/value | High price for performance, raising buyer regret risk. | Better balance of price and reliability in mid‑range picks. |

| Regret trigger | Settings slip during long sessions, making long dough runs frustrating. | Less likely to force rework or repairs in typical mid‑range tools. |

Top failures

Why does the thickness setting drift during use?

Regret moment occurs when a long sheet of dough suddenly changes thickness mid‑roll, forcing rework.

Pattern statement: this is a primary issue seen repeatedly in user feedback.

Usage context anchor: drift shows up during long sessions or when rolling stiffer doughs.

Category contrast line: this feels worse than normal because most mid‑range sheeters hold settings across multi‑pass jobs.

Is the machine fragile or likely to fail after a few uses?

- Early sign loose handle connection noticed after repeated tightening attempts.

- Frequency signal commonly reported as a secondary issue across reviews.

- Cause appears linked to thin fasteners and light structural parts under stress.

- Impact leads to wobble and uneven rolling, increasing wasted dough.

- Fix attempts often require added hardware or glue, adding time and cost.

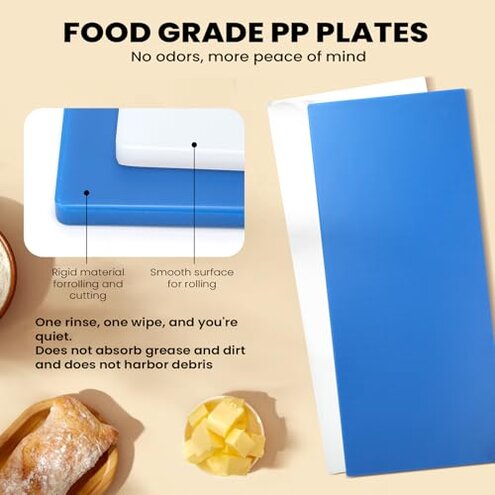

Will cleaning and assembly add unexpected work?

- Early sign stubborn dough pockets around rollers after typical use.

- Frequency reported as a primary complaint by many users.

- Cause small crevices and multi‑part assembly trap residue.

- Impact means longer cleanup than advertised and occasional hand scraping.

- Attempts to dishwasher parts are mixed; some users still hand wash.

- Hidden requirement you may need extra tools to fully disassemble for deep clean.

Does this product demand extra time, money, or skills to keep working?

- Hidden cost some owners add reinforcements or replace hardware after months.

- Skill need basic tools and small repairs are commonly needed to restore performance.

- Long term wear on thin parts becomes more evident after repeated heavy use.

- Scope this is a secondary pattern but more disruptive than expected.

- Impact added maintenance raises total ownership cost above similar models.

- Workaround users mention rigid bench mounting to reduce wobble and slippage.

- Expectation it’s sold as ready‑to‑use, but practical setups often need reinforcement.

Illustrative excerpts

Illustrative: "Thickness changed mid‑roll, had to start again from scratch." — primary pattern.

Illustrative: "Handle wobbled after a month of home use." — secondary pattern.

Illustrative: "Needed extra screws and a clamp to steady it." — edge‑case pattern.

Who should avoid this

- High‑volume bakers who run long dough sessions and need stable thickness settings.

- Buyers wanting low maintenance because cleaning and minor repairs are commonly required.

- Shoppers on a strict budget due to the product's high price and potential extra costs for fixes.

Who this is actually good for

- Occasional home bakers who make dough infrequently and can accept occasional adjustment.

- DIY tinkerers who are comfortable adding hardware or reinforcing mounts.

- Space‑limited cooks who value the compact footprint and can tolerate extra upkeep.

Expectation vs reality

- Expectation: "Adjustable settings stay fixed during use," which is reasonable for this category.

- Reality: settings often drift during extended rolling, causing rework and wasted time.

- Expectation: "Easy dishwasher cleaning" promised in marketing.

- Reality: actual cleanup frequently requires disassembly and hand tools to remove trapped dough.

Safer alternatives

- Choose reinforced models with confirmed stable thickness controls to avoid mid‑roll drift.

- Pick heavy‑duty frames or stainless designs if you plan repeated heavy use.

- Look for simple disassembly and flat, smooth roller housings to reduce cleanup time.

- Compare total ownership cost not just purchase price; factor likely repairs and added hardware.

The bottom line

Main regret is thickness settings slipping during real dough runs, which forces rework and waste.

Why it matters this exceeds normal category risk because it combines stability problems with higher‑than‑expected maintenance and cost.

Verdict avoid this model unless you accept extra upkeep, reinforcement, and possible repairs to reach reliable performance.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.