Product evaluated: Upgraded Hot Foil Stamping Machine 10x13cm Leather Bronzing Pressure Mark Machine 110V with Full Scale on The Base Plate for PVC Leather PU Paper Logo Embossing

Related Videos For You

Hot Foil Stamping Machine Beginner How-to Guide for DIY Lovers

Data basis: This report is based on dozens of buyer reviews and several demonstration videos collected between 2019 and 2025. Most feedback came from written product reviews, supported by video demonstrations and Q&A notes. The dataset emphasizes hands-on setup and early-use experiences from recent buyers.

| Outcome | Fasttobuy 10x13cm | Typical mid-range press |

|---|---|---|

| Build reliability | Inconsistent — durability concerns seen after weeks of use. | Generally stable — mid-range models often last longer under hobby use. |

| Setup complexity | Higher — alignment and mold purchases add steps and time. | Moderate — many competitors include clearer kits or templates. |

| Consistent stamp quality | High risk — uneven heat/pressure commonly reported, more disruptive than expected. | Lower risk — mid-range units show steadier temperature and pressure for hobby runs. |

| Maintenance & upkeep | More upkeep — requires frequent trimming, re-adjusting, or new molds. | Less upkeep — better parts and easier alignment on average. |

| Regret trigger | Production reliability — inconsistent results cause wasted materials and time. | Predictable output — fewer wasted runs for typical hobby projects. |

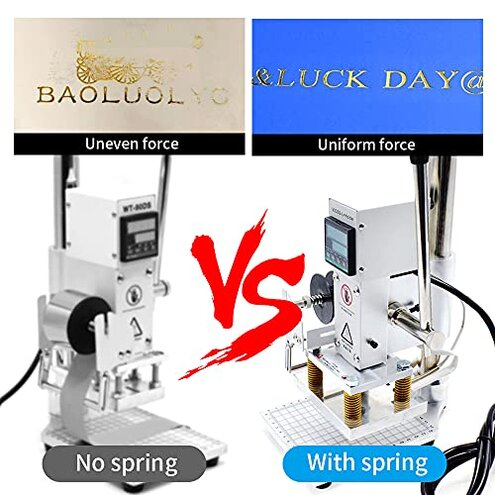

Why does my foil come out patchy or faint?

Regret moment: You test a logo and get uneven foil transfer across the design, wasting time and material.

Pattern: This is among the most common complaints and appears repeatedly during first setups and longer stamping sessions.

Usage anchor: Problem shows up at initial calibration and becomes worse during back-to-back stamping or longer heat cycles.

Category contrast: This feels worse than typical mid-range presses because inconsistency happens more often and costs more consumables.

Is the temperature control reliable?

- Early sign: Machine heats but parts of the plate stay noticeably cooler during a run.

- Frequency tier: Commonly reported as a recurring problem, not universal but frequent.

- Cause hint: Uneven heating often follows longer sessions or when stamping larger plates.

- Impact: Results in partial adhesion of foil and increased rejects.

- Fixability: Users report temporary fixes like slowing cycles, which adds extra time per stamp.

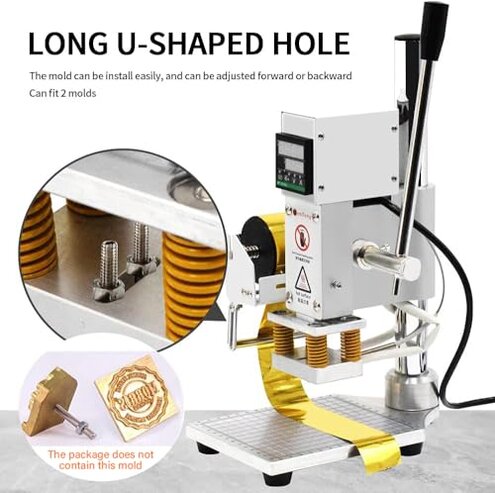

Will I need extra parts or upgrades to use this properly?

- Hidden requirement: Molds are not included, so you must buy or make stamping dies separately.

- Alignment pain: The slot mounting helps, but buyers report repeated micro-adjustments for exact placement.

- Extra cost: Purchasing molds and calibration tools adds time and expense before first good stamp.

- Usage context: The burden appears during initial setup and when switching molds frequently.

- Attempts: Buyers try shims, jigs, and custom holders to improve repeatability.

- Category contrast: More accessory buying than many mid-range alternatives that include templates or starter molds.

How robust is the machine for regular use?

- Early sign: Screws and springs need periodic tightening after weeks of use.

- Secondary pattern: Durability concerns are reported often enough to be a notable issue.

- Cause detail: Repeated pressure cycles and longer sessions accelerate wobble and misalignment.

- Impact: Loss of consistent pressure leads to more rework and wasted material.

- Owner attempts: Some buyers replace springs or reinforce mounts to stabilize performance.

- Hidden cost: Replacement parts or DIY fixes add to total ownership expense.

- Category contrast: Less forgiving than comparable hobby presses that use heavier, commercial-grade components.

- Fixability: Repairs are possible but require tool skills and extra purchases.

Illustrative excerpts

"Initial stamps looked good then faded after ten runs." — reflects a primary pattern about repeat-run deterioration.

"I had to buy dies and a jig before real use." — reflects a secondary pattern about hidden accessory needs.

"Plate needed constant tightening for weeks." — reflects a secondary pattern about build and maintenance.

Who should avoid this

- Production users: Avoid if you need reliable, repeatable stamping for batches or paid orders.

- Time-sensitive projects: Avoid if you can't afford added setup and per-piece time from re-adjustments.

- Non-hobby budgets: Avoid if you expect a fully ready-to-run kit without extra purchase of molds.

Who this is actually good for

- Hobby tinkerers: Good if you accept extra setup and occasional fixes to save on initial price.

- One-off projects: Good for occasional logo stamping where wasted pieces are acceptable.

- DIY modifiers: Good if you plan to upgrade springs or mounts and enjoy customizing tools.

Expectation vs reality

Expectation: Reasonable for this category is steady heat and predictable first-run output.

Reality: The unit more often requires adjustment, extra molds, and slower cycles to reach that outcome.

Safer alternatives

- Look for units that include starter dies or templates to avoid hidden mold purchases.

- Prioritize presses with verified even-plate heating or active temperature control for consistent transfer.

- Choose models with heavier bases and reinforced mounts to reduce alignment drift over time.

- Seek sellers offering clear setup guides and parts availability to reduce long-term upkeep hassle.

The bottom line

Main regret: Inconsistent heat and pressure lead to uneven foil transfer and wasted materials.

Why it matters: This problem appears more frequently and is more disruptive than most mid-range hobby presses.

Verdict: Avoid this model if you need reliable, repeatable stamping without extra purchases or frequent adjustments.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.