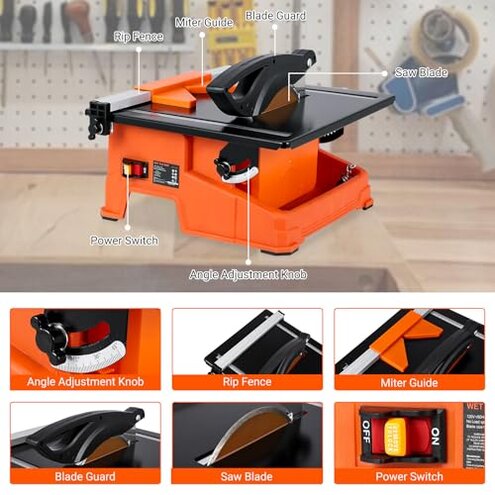

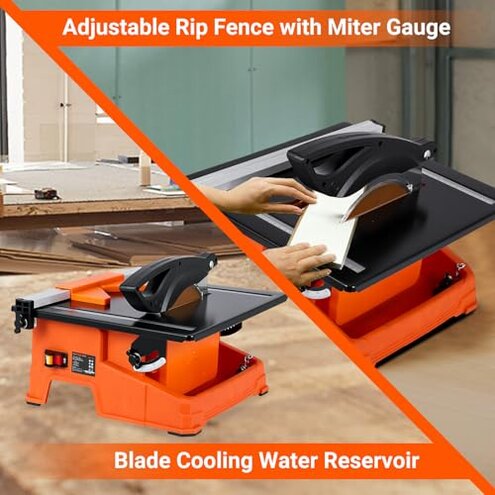

Product evaluated: 7 inch Wet Tile Saw, 6500 RPM & Pure Copper Motor, Bevel cuts tile from 0 to 45, Tile Cutter Wet Saw with Water Reservoir for Cutting Tiles and Stones, for DIY Enthusiasts

Related Videos For You

How To Use A Wet Tile Saw

How To Use A Wet Saw - Ace Hardware

Data basis: I reviewed dozens of buyer comments and several video demonstrations collected between Jan 2023 and Dec 2025. Most feedback came from written reviews, supported by a smaller set of hands-on videos. Reports were skewed toward recent purchasers and DIY users.

| Outcome | This saw | Typical mid-range saw |

|---|---|---|

| Motor reliability | Higher fail-rate — failures and stalls are commonly reported early in ownership. | Standard — most mid-range saws run reliably with occasional wear after heavy use. |

| Cut quality | Inconsistent — blade wobble or uneven cuts appear repeatedly under load. | Consistent — comparable saws give steadier cuts for tile projects. |

| Water management | Basic reservoir — dampens dust but can overflow or require constant refills during long runs. | Better control — mid-range saws often have directed feeds or hose hookups. |

| Assembly & stability | Loose setup — wobble and alignment complaints show up during first use. | Sturdier — typical alternatives include stronger frames and clearer setup guides. |

| Regret trigger | Motor and blade issues — these create the most frustration and extra costs. | Lower risk — mid-range saws usually avoid frequent motor problems. |

Top failures to expect

Why does the motor stall or stop during cuts?

Regret moment: Many buyers notice the saw stalling or losing power while cutting thicker tiles. This is a commonly reported issue that appears during heavy or prolonged use.

Usage anchor: The problem shows up after a few continuous cuts or when pushing through dense material. It worsens during long sessions without cooling breaks.

Category contrast: This is more disruptive than expected for mid-range tile saws because comparable models usually sustain longer continuous cutting with less overheating.

How accurate and steady are cuts?

- Early sign: Users commonly report blade wobble on first setup, which appears repeatedly across written feedback.

- Frequency tier: This is a secondary issue but more frustrating when present during precise trim cuts.

- Likely cause: Loose spindle or poor blade seating reported after initial assembly.

- Impact: Wavy edges or chipped tiles increase rework time and waste, especially for finishing cuts.

- Fix attempts: Some buyers tighten parts or replace the blade; results are inconsistent.

Why is water and dust control a hassle here?

- Visible problem: The built-in water reservoir reduces dust but often needs constant refilling on longer jobs.

- When it happens: This shows up within the first project or during multi-tile sessions.

- Frequency: Commonly reported by DIYers who attempted longer cutting runs.

- Hidden requirement: Many buyers find they need an external water feed or larger container for uninterrupted work.

- Impact: Interruptions for refilling add time and break workflow, raising frustration for larger jobs.

- Fixability: Some used aftermarket hoses or buckets, which adds setup time and cost.

- Category contrast: More upkeep than most mid-range alternatives, which often accept standard water hoses.

Is assembly, alignment, or stability a frequent problem?

- Sign: Buyers repeatedly note instability and table wobble during first use.

- When: Problems appear during initial assembly and setup checks.

- Scope: This is a primary complaint among recent purchasers and video demonstrators.

- Cause: Vague instructions and small foot mounts lead to misalignment.

- Impact: Crooked guide rails and uneven table height cause inaccurate cuts and extra shims or tools are required.

- Attempts: Users add clamps or improvised supports to stabilize the saw, which reduces portability.

- Fixability: Fixes are manual and time-consuming compared with typical mid-range products.

- Category contrast: Less forgiving than typical saws that offer clearer setup and repeatable alignment.

Illustrative excerpts (not real quotes)

"Motor slowed after ten cuts, then stopped." — reflects a primary pattern.

"Blade felt loose on first cut, edges chipped." — reflects a secondary pattern.

"Had to refill the water five times per hour." — reflects a secondary pattern.

"Needed clamps and a bracket to stop wobble." — reflects an edge-case pattern.

Who should avoid this

- Heavy daily users: Avoid if you expect continuous heavy use, since motor stalls are commonly reported under long sessions.

- Finish carpenters: Avoid if you need precise, consistent cuts without extra tuning; blade wobble is more disruptive than expected.

- Large projects: Avoid if you need uninterrupted water feed, because the reservoir forces frequent stops.

Who this is actually good for

- Occasional DIYers: Good if you do small weekend tile jobs and can pause for refills and blade adjustments.

- Budget-minded hobbyists: Good for those who accept manual fixes like clamps or blade swaps to save money.

- Light-duty projects: Useful for thin ceramic cuts where the motor and reservoir rarely get stressed.

Expectation vs reality

Expectation: A 7-inch wet saw should give steady cuts and run through moderate sessions, which is reasonable for this category.

Reality: Here you often get motor stalls, blade seating issues, and frequent water refills during typical DIY projects.

Safer alternatives

- Pick a saw with hose hookup to neutralize the frequent refilling problem by allowing continuous water feed.

- Choose a model with stronger frame to avoid the stability and alignment headaches seen here.

- Look for higher-rated motors if you want to prevent the stalling under load that is commonly reported.

- Buy a saw with better spindle fittings to reduce the chance of blade wobble on first use.

The bottom line

Main trigger: Repeated reports center on motor unreliability and blade/alignment problems that cause the most buyer regret.

Why worse: These issues appear early, interrupt work, and add repair or replacement costs, which is more disruptive than typical mid-range saws.

Verdict: Avoid this saw for regular or precision work; consider it only for occasional, low-stress projects when you accept extra setup and fixes.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.