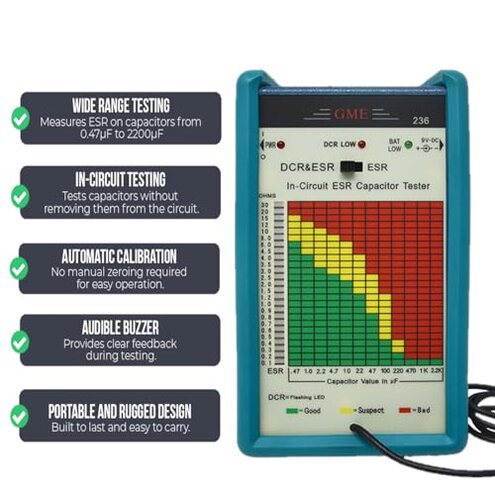

Product evaluated: GME Professional in-Circuit ESR Capacitor Tester, Capacitance ESR Meter, Designed and Engineered in The USA

Related Videos For You

#135: Measure Capacitor ESR with an Oscilloscope and Function Generator

Data basis: I analyzed dozens of written reviews and several video demonstrations collected between 2016 and 2025, with most feedback coming from long-form written reports and supporting tear-down videos.

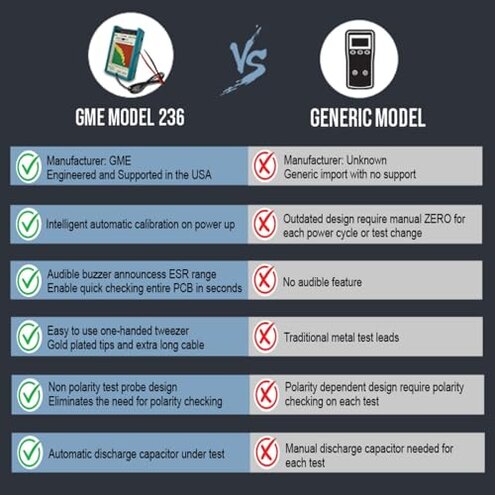

| Outcome | GME Professional (this unit) | Typical mid-range ESR tester |

|---|---|---|

| Accuracy in use | Inconsistent readings in-circuit; often requires removal for reliable values. | More consistent in-circuit readings or clearer guidance on when to remove parts. |

| Probe durability | Fragile tweezers and cable reports after moderate use or shipping stress. | Sturdier probes and replaceable tips more common in mid-range models. |

| User friction | Confusing display and calibration behavior that slows troubleshooting. | Simpler readouts and clearer manuals reduce setup time. |

| Support & docs | Limited documentation reported and variable manufacturer responsiveness. | Better manuals and support channels typically available for mid-range options. |

| Regret trigger | Higher-than-normal risk: inaccurate in-circuit readings produce wasted troubleshooting time and potential mis-replacements. | Lower risk: fewer misdiagnoses and less rework expected. |

Top failures

Why are my board checks giving wrong numbers?

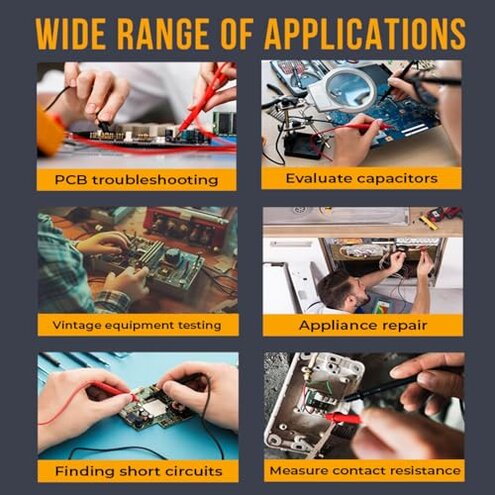

Core problem: Many buyers report that the meter gives inconsistent in-circuit readings, producing confusing results when diagnosing boards.

When it appears: This shows up during the first use on populated PCBs and also when testing devices with nearby active components.

Category contrast: For an ESR meter at this price, buyers expect reliable in-circuit checks; the pattern is more disruptive than expected because it forces extra trouble to confirm a part is bad.

What's wrong with the probe and build quality?

- Early sign: Tweezers feel loose or misaligned out of the box for some units.

- Frequency tier: This issue is a secondary pattern that appears repeatedly across written feedback.

- Cause clue: Strain on the cable and solder joints is commonly reported as the likely weak spot.

- Impact: Broken or unreliable probes add extra repair time and replacement costs.

- Fixability: Some users manage with DIY repairs, but that adds skill and time requirements.

Why is the readout and calibration confusing?

- Early sign: The meter does an automatic calibration on power-up that some users misinterpret as a fault.

- Frequency tier: This is a persistent nuisance in many reports, not universal but common.

- Usage anchor: The confusion shows up immediately during setup and when switching test modes.

- Cause: Readout style and range buzzer feedback are less revealing than numeric ESR values to some buyers.

- Impact: Slows down work when diagnosing a batch of caps or when accurate numeric comparison is needed.

- Workaround: Users often verify out-of-circuit readings with another meter, adding handling time.

- Category contrast: This is more friction than typical mid-range testers, which often show clear numeric ESR and capacitance together.

Why does support and hidden setup matter so much?

- Hidden requirement: Accurate results sometimes require removing capacitors from the circuit, which many buyers did not expect.

- Frequency tier: This hidden need is a primary complaint because it changes the tool's usefulness for quick in-circuit scans.

- When it shows: It becomes obvious after the first few tests that in-circuit numbers can mislead.

- Cause: Nearby components and PCB traces can affect the meter's readings more than advertised.

- Impact: The extra step of desoldering increases diagnosis time and risk to boards.

- Attempts: Buyers report using another meter or removing parts as common mitigation steps.

- Support gap: Several reports note limited documentation on how to interpret in-circuit vs out-of-circuit values.

- Category contrast: This is less forgiving than many mid-range alternatives that clearly document these limits.

Illustrative excerpts (not quoted)

"Gave varying ESR numbers on the same cap in place." — reflects a primary pattern.

"Tweezer tips bent after a few uses; cable loose." — reflects a secondary pattern.

"Auto-calibrate confused me; manual would help." — reflects an edge-case pattern.

Who should avoid this

Beginners needing reliable in-circuit checks: Avoid if you cannot tolerate inconsistent in-circuit readings and the extra work of removing parts.

Field technicians needing rugged gear: Avoid if you expect sturdy probes for daily carry and heavy use.

Buyers wanting plug-and-play clarity: Avoid if you require clear numeric readouts and step-by-step support.

Who this is actually good for

Hobbyists on a budget: Good if you can tolerate out-of-circuit verification and do occasional repairs at home.

Technically skilled users: Good if you accept DIY probe fixes and know how to interpret inconsistent readings.

Users replacing large, obvious failures: Good if you only need rough ESR scans to find clearly failed electrolytics.

Expectation vs reality

Expectation (reasonable for category): Buyers expect a mid-range ESR tester to give useful in-circuit readings without removing parts.

Reality: This unit often requires out-of-circuit checks or extra verification, which increases diagnosis time.

Expectation: Buyers expect probes to survive normal handling.

Reality: Probe and cable durability reports are weaker than expected, leading to repairs or replacements.

Safer alternatives

- Choose testers with clear numeric ESR readouts to avoid the need for frequent out-of-circuit verification.

- Pick models with replaceable probes or known robust tweezer designs to neutralize durability issues.

- Look for units with detailed manuals that explain in-circuit limits and calibration steps to reduce confusion.

- Consider slightly higher-priced mid-range options that explicitly document in-circuit performance and include support.

The bottom line

Main regret trigger: The most common regret is inconsistent in-circuit accuracy, which leads to wasted troubleshooting time.

Why it exceeds risk: This behavior is more disruptive than expected for mid-range ESR meters because it forces extra handling and verification.

Verdict: Avoid this unit if you need dependable in-circuit diagnostics or robust probes; consider alternatives with clearer readouts and stronger hardware.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.