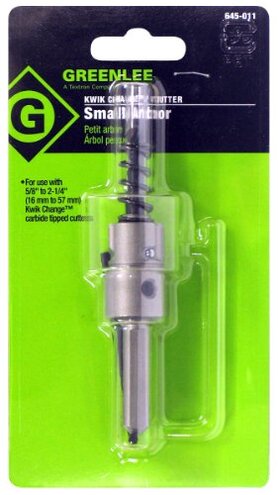

Product evaluated: Greenlee 645-011 Small Arbor for 5/8" - 2-1/4" Kwik Change Carbide-Tipped Hole Cutter

Related Videos For You

How To Assemble & Use Quick-Hitch Arbor To Hole Saw

How to Use a Hole Saw | Ask This Old House

Data basis: This report is built from dozens of buyer reports and a handful of video demonstrations collected through June 2024, with most feedback coming from written reviews supported by short visual demos.

| Outcome | Greenlee 645-011 | Typical mid-range arbor |

|---|---|---|

| Build quality | Mixed reports of early wear and loose threads under heavy use. | More consistent fit and finish with predictable lifespan for hobby-to-pro use. |

| Compatibility | Fit issues appear repeatedly when used with non-Greenlee cutters or older mandrels. | Broader fit across brands with fewer adapter needs. |

| Stability during cut | Higher risk of wobble or loosening mid-cut, especially in long runs. | Lower risk—most mid-range arbors stay tight for repeated cuts. |

| Replacement frequency | Earlier replacement reported after frequent metal cutting sessions. | Typical lifespan that meets expectations for mid-range tools. |

| Regret trigger | Loosening during use that interrupts work and risks damaged holes. | Fewer interruptions—mid-range alternates usually avoid this problem. |

Why does the arbor loosen during cuts?

Regret moment: The most disruptive complaint is the arbor loosening while cutting, which stops the job and can ruin the hole.

Pattern signal: This appears repeatedly across reports and is a primary issue rather than an edge case.

Usage anchor: It shows up on first few uses and gets worse during long cutting sessions or when cutting harder material.

Category contrast: Most mid-range arbors stay tight longer, so this feels more disruptive than typical for hobby or jobsite tooling.

Why is fitment and compatibility frustrating?

- Early sign: Tolerance mismatch shows immediately when the cutter won’t seat squarely.

- Frequency tier: Often reported as a secondary issue that accompanies stability problems.

- Cause: Varied shank sizes and older cutter designs increase the chance of poor fit.

- Impact: Wasted setup time and extra adapters or tools needed before cutting.

- Fixability: Some buyers solved it with shims or brand-specific pilots, but that adds cost.

How quickly does the arbor wear or fail?

- Visible wear: Scoring and thread damage appears after repeated metal cuts.

- Frequency tier: This is a secondary issue that becomes primary with frequent professional use.

- Impact on use: Worn parts lead to louder vibration and less accurate holes.

- When it worsens: Heavy daily use and cutting abrasive material accelerate wear.

- Attempts to fix: Re-tightening helps briefly but does not stop progressive loosening.

- Category contrast: More upkeep than most mid-range alternatives, raising total ownership cost.

Are there hidden tools or parts you need?

- Hidden requirement: Some buyers needed extra pilot bits or specific spanners not included with the arbor.

- Early sign: You notice missing accessories at setup when the pilot doesn’t match.

- Cause: The arbor assumes compatible cutters and pilots, which is not universal.

- Impact: Extra purchases and downtime before the tool becomes usable.

- Fixability: Aftermarket pilots and wrenches work but add unexpected cost.

- Frequency tier: Less frequent than loosening, but persistent for buyers mixing brands.

- Category contrast: Less forgiving than typical options that include adapters or clearer specs.

Illustrative excerpts

Excerpt: "Arbor started to wobble after two cuts, ruined the hole and slowed me down."

Pattern: This reflects a primary pattern tied to stability during use.

Excerpt: "Needed a special pilot that wasn’t in the box, cost extra time and money."

Pattern: This reflects a secondary pattern about hidden requirements.

Excerpt: "Threads showed wear after a week of frequent metal work, not what I expected."

Pattern: This reflects a secondary pattern tied to durability under heavy use.

Who should avoid this

- Professionals who run long cutting sessions; the loosening risk is worse than normal for daily use.

- Multi-brand shops that switch cutters often; hidden fit needs add downtime and extra parts.

- Precision users who require clean, accurate holes; mid-cut wobble increases scrap risk.

Who this is actually good for

- Casual DIYers who cut occasionally and can accept extra setup time or re-tightening between cuts.

- Single-brand users who already own compatible Greenlee cutters and pilots and avoid fit issues.

- Budget-minded hobbyists willing to buy small adapters cheaply rather than a premium arbor.

Expectation vs reality

Expectation: Reasonable for this category is a snug fit and steady cut for several uses without adjustment.

Reality: Many buyers report having to re-tighten or add adapters after the first few cuts.

Expectation: Most mid-range arbors tolerate daily jobsite use without rapid wear.

Reality: This arbor shows faster thread and shank wear under repeated heavy cutting sessions.

Safer alternatives

- Choose arbors with documented multi-brand compatibility to avoid hidden pilot or adapter needs.

- Prefer options that include spanners or pilots in the box to reduce surprise purchases.

- Look for reviews that highlight mid-cut stability to neutralize the loosening risk.

- Consider hardened shanks or premium mid-range brands if you do daily metal cutting to avoid premature wear.

The bottom line

Main regret: The primary problem is mid-cut loosening that interrupts work and risks ruined holes.

Why worse: This product shows higher-than-normal stability and fit issues compared with typical mid-range arbors.

Verdict: Avoid this arbor if you need reliable, daily performance, but it can work for occasional DIY or brand-matched setups.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.