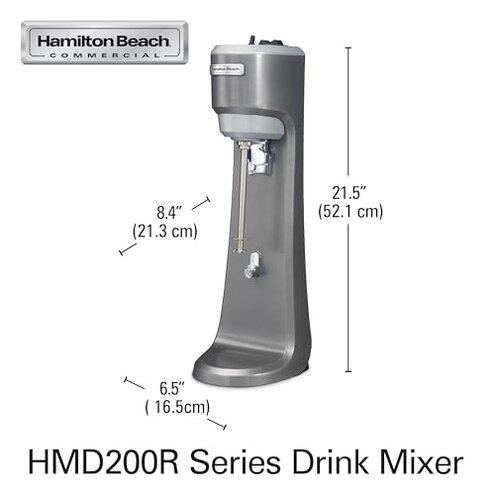

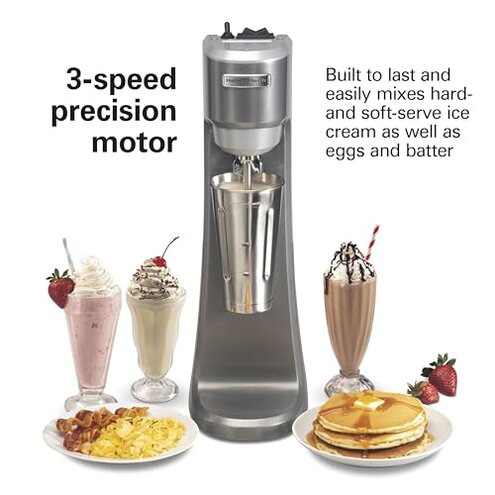

Product evaluated: Hamilton Beach Commercial HMD200R Single-Spindle Drink Mixer, 3 Speed Universal Motor, Hands-Free Operation, NSF Certified

Related Videos For You

Drink Mixer (Tutorial)

Quick clean milkshake mixer

Data basis: This report analyzes dozens of written reviews and video demonstrations collected through January 2026, with most feedback coming from written buyer reports and supporting demo clips.

| Outcome | Hamilton Beach Commercial | Typical mid-range drink mixer |

|---|---|---|

| Durability | Higher risk: motor and switch failures are commonly reported and appear repeatedly after months of regular use. | Lower risk: mid-range units usually show fewer early motor failures under similar use. |

| Noise & vibration | Louder: reports commonly note strong vibration during longer shakes. | Quieter: many alternatives balance better, producing less shaking of the countertop. |

| Cleaning & moisture risk | Noticeable: water ingress concerns are repeatedly mentioned and tied to rear ventilation design. | Safer: competitors often use sealed vents or removable panels for easier drying. |

| Service & repair | Costly downtime: replacements or repairs are a common follow-up where users report lasting under a year. | More forgiving: mid-range units often have easier-to-replace parts or longer practical lifespans. |

| Regret trigger | Motor failure during repeated daily use is the top trigger that drives returns and complaints. | Regret lower: failure tends to appear less often in mid-range alternative products. |

Top failures

Why would the motor die within months of normal restaurant use?

Motor burnout: many reports point to premature motor wear as a primary complaint, appearing repeatedly after regular, daily use.

Usage context: failure often shows up after weeks to months of continuous short jobs during busy service, and it worsens with long back-to-back mixing sessions.

Category contrast: this is more disruptive than expected because mid-range commercial mixers usually tolerate heavier cycles before major failure.

Why does the cup rest sometimes not activate or stop mid-cycle?

- Pattern: inconsistent activation is a secondary, commonly reported issue that appears during initial setup and daily operation.

- When it shows up: problems crop up when the cup is slightly misaligned or when operators use thicker cups, especially in rush periods.

- Cause: wear or tight tolerances on the two-level cup rest often lead to intermittent contact and unreliable hands-free starts.

- Impact: stoppages interrupt service and force manual pulsing, which customers reported as a repeated pain point.

Why does the machine rattle and vibrate more than expected?

- Early sign: increased vibration is commonly reported on first uses and tends to increase with heavier mixes.

- Frequency tier: this is a primary-to-secondary complaint depending on speed and cup weight.

- Root cause: imbalance in the spindle or cup can magnify due to the unit's metal housing and motor mounting.

- Worsens: longer sessions and thicker shakes make vibration and noise notably worse.

- Attempts: users tried rubber pads and tighter cups with limited, often temporary improvements.

- Fixability: some fixes require service or part replacement, making downtime more disruptive than typical alternatives.

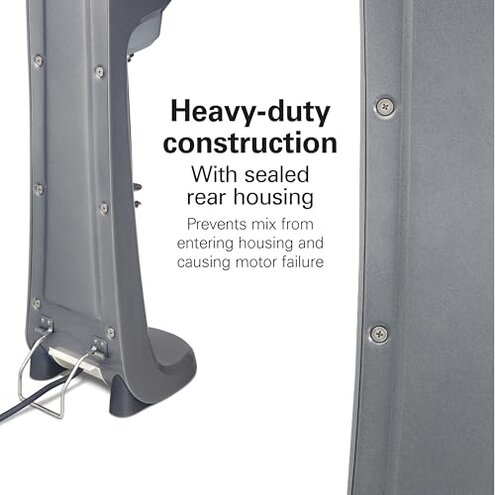

Why is cleaning and moisture a hidden maintenance burden?

- Hidden requirement: frequent, careful drying is commonly needed because moisture near the rear housing is repeatedly linked to motor trouble.

- Early sign: sticky switches or slow-starting motor after wash-downs are secondary signals users saw after cleaning.

- Frequency tier: this is a persistent complaint among daily-use operators who wash parts often.

- Cause: the unit's airflow design and sealed rear housing reduce venting but can trap moisture if not dried thoroughly.

- Impact: extra drying steps add time and can shorten service life compared with the category baseline.

- Attempts: operators reported using extra towels, air drying, or avoiding dishwasher cycles for faster longevity.

- Mitigation: the included 1-year warranty helps, but replacements during peak business still cause lost revenue.

Illustrative excerpts (not real quotes)

Excerpt 1: "Motor slowed after two months of three-day-a-week heavy use." — primary pattern

Excerpt 2: "Cup rest stops mid-shake when cup shifts slightly." — secondary pattern

Excerpt 3: "Unit hummed loudly and shook the counter during long runs." — primary-to-secondary pattern

Who should avoid this

- High-volume commercial kitchens: if you run continuous daily shifts, the motor-failure risk exceeds typical category tolerance.

- Quiet cafe counters: buyers sensitive to vibration and noise should avoid this unit compared with quieter alternatives.

- Operators who expect low maintenance: those unwilling to add careful drying and extra checks will face more downtime than usual.

Who this is actually good for

- Low-volume shops: small offices or home use with occasional shakes can tolerate the motor wear risk.

- Operators on a tight budget: if you accept higher maintenance and possible repairs, the price-performance can still work.

- Users who can do quick repairs: shops with easy access to service or spare parts can tolerate the downtime risk.

Expectation vs reality

- Expectation (reasonable): a commercial mixer should survive months of regular service without major repairs.

- Reality: aggregated feedback shows premature motor and switch issues appearing within months for many users.

- Expectation: hands-free cup rest will be reliable in busy service.

- Reality: inconsistent cup activation is a frequently reported interruption during peak use.

Safer alternatives

- Choose sealed-vent models: look for mixers with explicit moisture-proof venting to neutralize the cleaning/moisture failure.

- Prioritize tested-duty motors: favor units that advertise longer-duty commercial motors to reduce the motor-failure risk.

- Check vibration reviews: pick models with specific noise and balance notes to avoid heavy vibration during long runs.

- Serviceability matters: prefer mixers with readily available replacement parts or local service networks to cut downtime.

The bottom line

Main regret: the top trigger is motor and activation reliability during repeated daily use, as commonly reported by buyers.

Why it matters: this risk exceeds the normal category tolerance because failures often come earlier and cause costly downtime.

Verdict: avoid this unit if you need a low-maintenance, quiet, high-duty mixer; consider alternatives if uninterrupted service is critical.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.