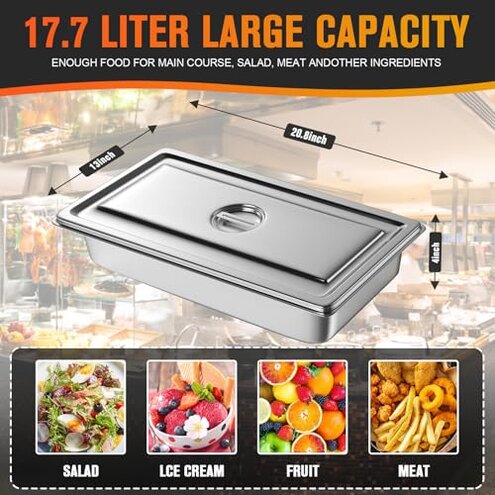

Product evaluated: Hotel Pan, Full Size Steam Table Pan 4" Deep Stainless Steam Table Pan with Lid Full Size Food Pan 20.8" L x 13" W Anti Jam Stainless Steel Buffet Pan Commercial Stainless Steel Pan (4 Pack)

Related Videos For You

Steam Pan Usage

Most common size restaurant Hotel pans.

Data basis: I analyzed dozens of buyer comments, short Q&A posts, and video demonstrations collected between 2022 and 2026, with most feedback coming from written reviews supported by demo clips and comment threads.

| Outcome | This product | Typical mid-range pan |

|---|---|---|

| Durability | Higher dent/warp risk appears repeatedly under heavy use or heat and is more disruptive than expected for the category. | Better resistance to warping and dents in everyday catering use. |

| Lid fit | Frequent fit problems reported that cause poor stacking and spilling during transport. | Secure lids and predictable stacking for most mid-range options. |

| Finish & handling | Polished finish often arrives scratched or with sharp edges that need cleanup. | Smoother edges and fewer finish defects out of the box. |

| Storage/stacking | Stacking issues reported when lids or pans distort after heat cycles. | Consistent nesting with less need for reshaping or padding. |

| Regret trigger | Warping under repeated heat is the main regret and is a higher-than-normal category risk. | Lower regret for warping with typical mid-range pans on daily use. |

Why did my pan warp or bend after a few uses?

Regret moment: Buyers commonly report warping during first weeks of regular use, especially after oven or steam-table cycles.

Pattern: This is a primary, recurring complaint across written reviews and demo videos and is more disruptive than expected for this class of pans.

Context: Warping usually appears after heat exposure and heavy scooping, and it worsens with repeated use or high-temperature service.

Category contrast: Unlike most mid-range hotel pans, this product's warping leads to stacking trouble and lid gaps that cause real service delays.

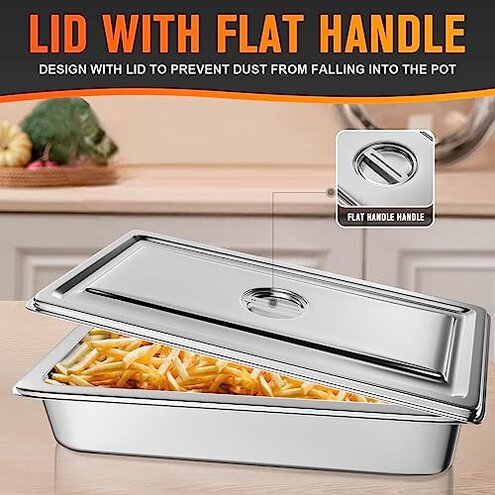

Why won’t the lids sit flush or stay in place?

- Fit problem: Lids are commonly reported as loose or misaligned, which causes spills during transport.

- When it shows: Issue appears at first setup and after pans bend from heat or knocks.

- Frequency tier: Secondary complaint that appears repeatedly enough to impact catering setups.

- Impact: Loose lids add time to packing and increase chance of cross-contamination or leakage.

- Fix attempts: Buyers often re-seat or tape lids as a workaround, adding steps to service routines.

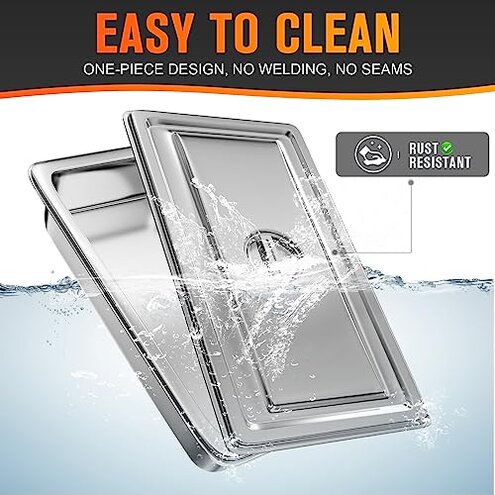

Are there finish defects, sharp edges, or dents out of the box?

- Surface defects: Scratches and minor dents are commonly reported on arrival by recent buyers.

- Early signs: Noticeable finish flaws are present on first inspection in many reports.

- Cause: Shipping and thin construction are commonly cited as contributors to out-of-box damage.

- Handling risk: Sharp curled edges can require extra cleanup or filing before safe use.

- Cleaning impact: Scratched finishes show wear faster and may trap food more than expected.

- Repairability: Minor dents are sometimes hammered flat, but that adds time and effort.

- Category contrast: More finish issues than typical mid-range pans, which raises maintenance needs.

Will shipping or stacking cause permanent damage over time?

- Shipping dents: Buyers often see dents after delivery, especially when packed with minimal padding.

- Stack stress: Stacking during storage can accelerate deformation after heat cycles.

- Long-term trend: Damage accumulates over months of daily catering use, not just on first use.

- Hidden requirement: Some users add protective trays or foam between pans to avoid future damage.

- Cost of workaround: Extra protective measures increase prep time and storage space needs.

- Fix attempts: Replacing distorted pans is a common but costly response for frequent caterers.

- Scope signal: Reports come from both single buyers and small catering operations, showing cross-use impact.

- Category contrast: More frequent and costly than typical mid-range pans that survive routine shipping and stacking.

Illustrative excerpts (not real quotes)

Excerpt: "Lid kept slipping during transport, food leaked into carrier tray." — Primary pattern

Excerpt: "Pan bent after first oven cycle and wouldn't sit flat in steam table." — Primary pattern

Excerpt: "Small dents and scratches on arrival required filing the edge." — Secondary pattern

Excerpt: "Had to add foam between pans to stop warping after repeated use." — Secondary pattern

Who should avoid this

Commercial caterers who run daily hot-service shifts and require reliable, warp-free pans should avoid this due to recurring deformation under heat.

Event transporters who move full pans frequently should avoid this because loose lids and early dents increase spill risk.

Buyers needing perfect out-of-box finish should avoid this if cosmetic appearance and smooth edges matter for front-of-house service.

Who this is actually good for

Low-frequency home hosts who use pans occasionally and can tolerate light dents should consider this if price and basic capacity matter more than heavy-duty longevity.

One-off caterers who need extra pans for occasional events and can inspect and recondition items before use may accept the trade-offs.

DIY modifiers who plan to reinforce edges or add padding can tolerate the hidden requirement because they can customize fit and stacking.

Expectation vs reality

Expectation: Buyers reasonably expect a full-size steam table pan to resist warping during normal oven or steam-table use.

Reality: This product commonly warps after repeated heat cycles, which is worse than a typical mid-range pan and causes extra work and replacements.

Expectation: Lids should sit flush and allow safe stacking and transport.

Reality: Loose lids are a frequent follow-on problem, forcing taping or additional packing steps to prevent leaks.

Safer alternatives

- Choose thicker-gauge pans to neutralize the warping under heat and reduce long-term replacement cost.

- Prioritize secure-fitting lids or models with locking lids to avoid the common spill and stacking issues described above.

- Inspect packaging and prefer sellers who offer protective shipping or accept easy returns to reduce out-of-box dents.

- Budget for padding if you keep these pans—foam or cardboard between pans prevents stacking stress and slows deformation.

- Buy from tested brands with documented heavy-use feedback if you need daily commercial performance.

The bottom line

Main regret: The primary issue is warping and lid-fit failures that appear during heat cycles and frequent handling.

Why worse: These failures exceed normal category risk because they disrupt stacking, transport, and service workflows.

Verdict: Avoid this product if you need durable, daily-use catering pans; consider it only for occasional home use or if you plan protective workarounds.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.