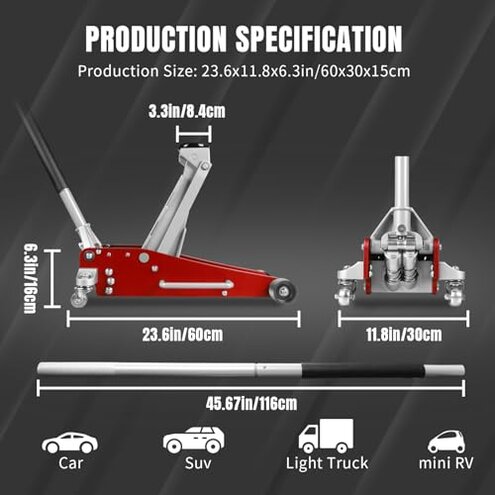

Product evaluated: Jack Boss 3 Ton Low Profile, Aluminum and Steel Racing Floor Jack with Dual Pistons Quick Lift Pump for Sport Utility Vehicle, Lifting Range 3-15/16" min to 18-5/16" max, Net Weight 58.5 lb, Red

Related Videos For You

How to safely lift any vehicle with a hydraulic floor jack! Unibody/body on frame vehicles shown!

Fill & Bleed a floor jack

Dozens of written reviews and several video demonstrations were analyzed for this report, collected from January 2021 through February 2026. Most feedback came from written product reviews, supported by hands-on videos and Q&A posts.

| Outcome | This Jack Boss | Typical Mid‑Range Jack |

|---|---|---|

| Build quality | Inconsistent—reports of loose welds and caster failure appear repeatedly. | More consistent—mid‑range alternatives usually show steadier assembly quality. |

| Hydraulic reliability | Higher‑than‑normal risk—pressure loss and fluid seepage are a common complaint. | Lower risk—many competitors hold pressure longer without maintenance. |

| Ease of use | Variable—dual pistons pump quickly but some users report stiff action and extra assembly steps. | Smoother—typical mid‑range jacks pump predictably out of the box. |

| Regret trigger | Lift failure—unexpected loss of lift during repeated use is the main regret driver. | Rare—mid‑range jacks more often fail only after heavy misuse or years of service. |

| Support & warranty | Limited—one‑year warranty reported, with mixed customer service outcomes. | Often better—some alternatives include longer warranties or clearer support responsiveness. |

Why might the jack lose lift during regular use?

Regret moment arrives when the jack drops or won’t hold a vehicle after several uses. Severity is high because loss of lift creates an immediate safety and workflow risk.

Pattern is commonly reported across feedback and ranks among the most common complaints. Usage often shows up after repeated lifts or in multi‑day garage work when the jack is used several times without servicing.

Category contrast—this is worse than typical mid‑range jacks because many competitors maintain pressure longer between maintenance cycles.

Are there obvious quality and wear problems?

- Appearance—paint chipping and surface rust appear repeatedly after short use, indicating finish fragility.

- Casters—wheels and swivels show loose bearings or cracking in a noticeable share of feedback.

- Saddle—rubber saddle slips or degrades faster than expected for this class.

- Weight handling—some users report wobble near the top of the lift, making high lifts feel unstable.

- Frequency tier—this is a secondary issue but more disruptive than typical cosmetic problems.

Will setup and parts slow me down?

- Missing fasteners—some buyers find bolts or pins absent on arrival, adding immediate assembly time.

- Poor instructions—manuals often lack clear torque settings or maintenance intervals.

- Handle fit—handle pieces sometimes require extra filing or force to engage the pump socket.

- Initial bleed—the jack commonly needs bleeding and oil checks before first use.

- Tool requirement—repair attempts usually demand basic hand tools and hydraulic fluid knowledge.

- Impact—these setup issues are a primary complaint and add minutes to hours before safe operation.

- Fixability—some fixes are straightforward, but others require replacement parts or returns.

Does the low‑profile design actually help low cars without extra fuss?

- Claim—low profile is useful, but some users report the minimum height still doesn’t fit very low frames.

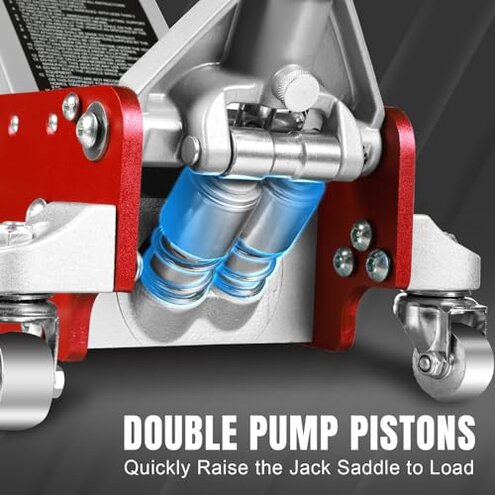

- Pumping effort—dual pistons pump fast but feel stiffer than expected during repeated lifts.

- Hidden requirement—buyers often must supply proper jack stands because the product doesn’t include rated stands, a common overlooked need.

- Frequency—this is a secondary pattern that appears across different users with low‑clearance cars.

- Performance—when fully loaded the jack can slow on the final inches, making precise positioning harder than typical jacks.

- Environment—cold garages or dirty floors worsen pumping stiffness and caster movement.

- Category contrast—worse than many mid‑range low jacks that prioritize smooth final‑stroke adjustment.

Illustrative excerpts

Illustrative: "Pump felt stiff and the jack lost height after a few uses, risky when under car." Primary

Illustrative: "Caster cracked after light use, made moving the jack difficult in my garage." Secondary

Illustrative: "Missing bolt delayed setup and I had to source parts locally." Secondary

Illustrative: "Low profile still rubbed on my aftermarket splitter, not as low as advertised." Edge‑case

Who should avoid this

- Frequent users—avoid if you perform daily or heavy repeated lifts because hydraulic reliability is a primary failure.

- Shops and pros—avoid if you need consistent uptime since quality and caster issues are more disruptive than typical for this category.

- Low‑clearance vehicles—avoid if you have extremely low splitters, as the claimed low profile may still be too tall.

Who this is actually good for

- Occasional home users—acceptable if you jack your car rarely and can verify lift each time before getting under the vehicle.

- Budget-minded DIYers—useful if you can tolerate extra maintenance and can perform simple repairs like bleeding or replacing a caster.

- Users with backup stands—works if you always use rated jack stands and treat the jack as a temporary lift tool only.

Expectation vs reality

- Expectation—you expect reliable lift across many uses, like most mid‑range jacks. Reality—pressure loss appears repeatedly after repeated lifts.

- Expectation—the low profile should clear most cars. Reality—some cars still scrape and need extra clearance checks.

- Expectation—assembly is quick out of the box. Reality—missing parts and vague instructions add setup time.

Safer alternatives

- Prioritize hydraulic reliability—look for jacks with documented long‑term pressure retention or longer warranties to avoid lift loss.

- Check build reviews—choose models with frequent praise for casters and saddles to avoid wear and wobble.

- Buy with support—prefer sellers that include clear spare parts or faster replacement policies to reduce downtime from missing hardware.

- Plan for maintenance—budget time for initial bleeding and periodic checks to prevent mid‑job failures.

- Confirm low clearance—measure your vehicle and compare minimum lift heights instead of relying solely on marketing numbers.

The bottom line

Main regret is unexpected loss of lift and inconsistent build quality that creates safety and downtime risks. Why worse—these issues appear more often and sooner than expected for similar mid‑range floor jacks. Verdict—avoid if you need frequent, reliable lifting; accept only with reserve, extra maintenance, and proper jack stands.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.