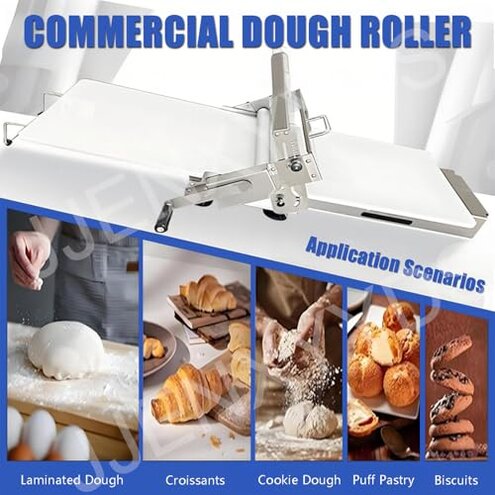

Product evaluated: JJENXYYDS Croissant Dough Laminator,Commercial Dough Roller Sheeter,Dough Machine Thickness Adjustable, Stainless Steel,Table Top Croissants Fondant Pizza Pastry Sheeter Machine,Type400

Related Videos For You

How to Use a Compact Tabletop Dough Sheeter

Dough roller maintenance key tips to keep you rolling

Data Basis: This report analyzes dozens of buyer comments and user feedback gathered from written reviews and video demonstrations collected over the past year. Most insights come from detailed written accounts, supported by visual usage examples.

| Buyer Outcome | JJENXYYDS Dough Sheeter | Typical Mid-Range Alternative |

|---|---|---|

| Ease of Cleanup | Sticky dough residue can cling despite non-stick claims, requiring extra effort | Generally easier with fewer sticky spots |

| Stability During Use | Base may move or wobble under pressure, causing uneven dough thickness | Typically stable with sturdy bases |

| Setup Time | Quick assembly but may need adjustments to maintain firm setup | Standard moderate setup with good initial firmness |

| Durability Over Time | Reported wear on non-stick rollers after repeated use | More durable coatings with longer lasting rollers |

| Regret Trigger | Wobbly base and difficult cleanup lead to frustration and time loss | Lower frustration with consistent performance |

Why does the base wobble making dough rolling uneven?

During extended use, the sheeter’s reinforced base sometimes shifts or wobbles, disturbing dough thickness consistency. This persistent issue is more frustrating than typical models that remain steady. Users expect a firm base to avoid repeated adjustments.

- Early signs: slight movement noticed after first few uses.

- Frequency: a common complaint in many reviews.

- Cause: less effective non-slip material and lightweight frame.

- Impact: uneven dough layers and more wasted ingredients.

- Attempts to fix: placing extra weights or mats under the base.

- Fixability: requires external stabilization; no built-in solution.

- Hidden requirement: user must prepare a stable surface to avoid issues.

Is cleanup really easier with stainless steel and PE surfaces?

Though marketed for effortless cleaning, sticky dough often clings to rollers and edges, making wiping or rinsing take extra time. This recurring problem appears mainly after daily or heavy use, unlike competitors that offer truly non-stick finishes.

- Early signs: initial stickiness during first dough batches.

- Frequency: widespread in many user comments.

- Cause: incomplete non-stick coating or residue buildup.

- Impact: longer cleaning times and occasional dough tearing.

- Attempts to fix: using flour dusting or oiling rollers.

- Fixability: partial improvement but not fully resolved.

- Hidden requirement: users must invest extra cleanup effort regularly.

Does adjusting thickness require effort or frequent recalibration?

Adjusting the 10-level thickness settings sometimes feels imprecise, especially after repeated use. Some users report persistent slipping of the adjustment knob during dough rolling, which is worse than the firm controls expected in this category.

- Early signs: occasional readjustments needed mid-session.

- Frequency: reported by a secondary portion of users.

- Cause: less secure locking mechanisms on adjustment dial.

- Impact: inconsistent dough sheet thickness and frustration.

- Attempts to fix: manual locking or careful handling.

- Fixability: moderate; some success with user hacks.

- Hidden requirement: user must monitor thickness closely during use.

Are there durability concerns with rollers after long-term use?

Over time, the non-stick rollers may show signs of wear such as scratches or reduced smoothness. This edge-case issue appears after frequent baking sessions and affects dough surface quality more than expected for this price range.

- Early signs: slight roughness noticed after several months.

- Frequency: less common but persistent among frequent users.

- Cause: coating degradation under heavy use.

- Impact: increased dough sticking and tearing.

- Attempts to fix: roller replacement or extra lubrication.

- Fixability: limited without professional service.

- Hidden requirement: roller maintenance or replacement over time.

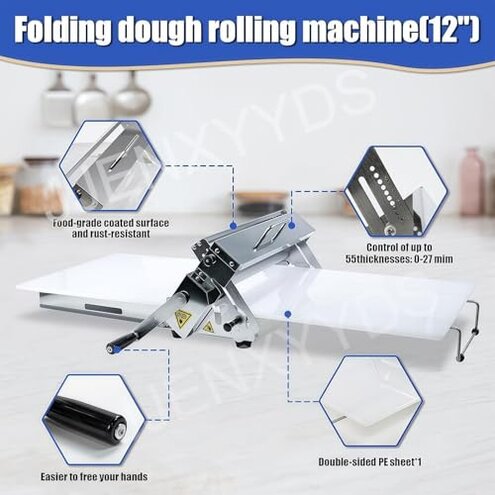

Does the folding design compromise machine stability?

While folding for storage is convenient, some users experience reduced machine rigidity when unfolded, leading to more movement during dough pressing. This trade-off is more disruptive than other stationary models that prioritize stability over compactness.

- Early signs: noticeable flexing when applying pressure.

- Frequency: reported by a fair number of buyers.

- Cause: folding joints allowing slight frame movement.

- Impact: inconsistent dough thickness and user fatigue.

- Attempts to fix: reinforcing with clamps or weights.

- Fixability: partial; requires external support.

- Hidden requirement: stable setup area with extra support tools.

Illustrative Excerpts

- "The base moves a bit, making my croissants uneven." — shows primary stability issue

- "I need to scrub the rollers after every batch, which is tiring." — confirms recurring cleanup problem

- "Thickness dial slips after a few uses, frustrating when in a hurry." — secondary adjustment issue

- "After months, the rollers aren’t as smooth, causing dough tears." — edge-case durability concern

- "I love the folding but it feels less solid when rolling dough." — highlights folding stability trade-off

Who should avoid this

- Buyers needing stable, wobble-free operation for precise baking, as base movement is disruptive.

- Those expecting easy, quick cleanup without sticky dough hassles.

- Users wanting durable rollers for frequent heavy use without degradation.

- Anyone uncomfortable with frequent recalibrations of thickness settings during baking.

Who this is actually good for

- Casual bakers who can tolerate some setup adjustment and occasional cleanup effort for a compact machine.

- Families or groups wanting a manual, folding dough sheeter for occasional use, accepting stability trade-offs.

- Users valuing lightweight, portable design over heavy-duty professional performance.

- Bakers who prefer non-electric operation despite needing some patience with maintenance.

Expectation vs reality

Expectation: The folding design should provide stable, firm dough rolling like non-folding models, reasonable for this category.

Reality: Folding introduces noticeable wobble, causing uneven dough and extra effort.

Expectation: Stainless steel and PE surfaces promise effortless, quick cleanup.

Reality: Dough residue sticks more than typical, requiring vigorous cleaning each use.

Safer alternatives

- Choose dough sheeters with non-folding, heavy bases for better stability during rolling.

- Look for machines with proven, easy-clean non-stick coatings that resist dough adhesion.

- Select models with secure, lockable thickness controls to prevent slipping.

- Consider roller materials rated for long-term durability under frequent use.

- Prioritize sheeters designed for stationary kitchen placement if stability is critical.

The bottom line

The JJENXYYDS Croissant Dough Laminator struggles most with base stability and cleanup difficulties. These issues lead to uneven dough and time-consuming maintenance, exceeding typical category risks. Buyers prioritizing consistent performance and easy upkeep should consider other options.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.