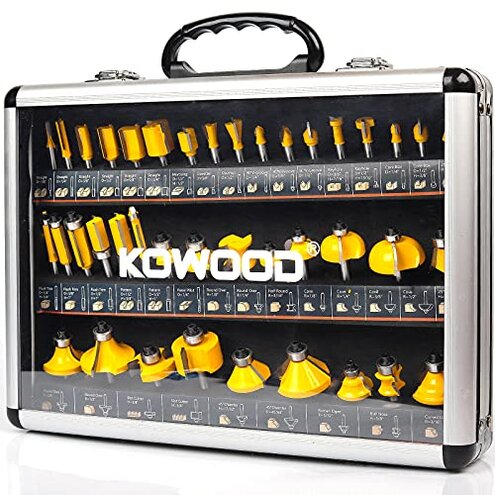

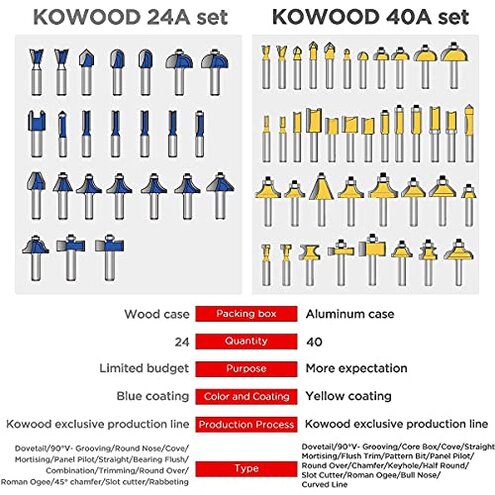

Product evaluated: KOWOOD Router Bits Set of 40 Pieces, 1/4 Inch Shank, 40A Expert Router Bit Kit.

Related Videos For You

99% of Beginners Don't Know the Basics of Router Bits

Clean and Sharpen Your Router Bits

Data basis: I analyzed dozens of buyer reviews and several video demonstrations collected between 2021 and 2024, with most feedback coming from written reviews supported by videos.

| Outcome | KOWOOD 40-piece set | Typical mid-range set |

|---|---|---|

| Cutting life | Shorter than expected — many buyers report dulling or chipping after repeated hardwood use. | Moderate — average mid-range sets last longer under similar use. |

| Fit/runout risk | Higher runout reports — some bits wobble at first use, especially at high RPMs. | Lower risk — mid-range bits more consistent in shank tolerance. |

| Case & inventory | Weak organization — case labeling and protection often criticized. | Better organized — typical sets protect bits and label clearly. |

| Price vs durability | Cheap price, but durability appears below category expectation. | Balanced — similar price often buys more consistent longevity. |

| Regret trigger | Carbide edge failure — among the most common complaints and most disruptive for woodworkers. | Less likely — typical mid-range alternatives trigger regret less often. |

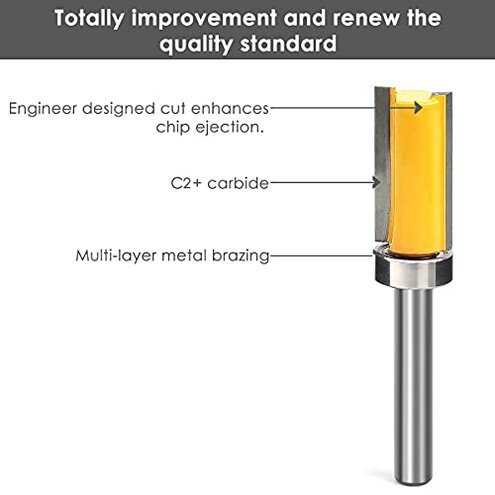

Why did my new bits dull or chip so quickly?

Regret moment: Buyers commonly report bits losing sharpness or chipping after only a few uses on hardwoods, making finishing and clean cuts worse than expected.

Pattern: This is a recurring complaint, seen repeatedly across written reviews and demonstrated clips.

When it shows up: Dulling usually appears after the first few sessions or after cutting tougher materials like oak or plywood with abrasive glue lines.

Category contrast: This durability is worse than typical mid-range sets, which more often hold an edge for longer under the same conditions.

Are these bits going to cause wobble or poor fit in my router?

- Usage anchor: Wobble is reported at first use, especially when running at high RPM or on extended bits.

- Frequency tier: This is a secondary but noticeable issue for many buyers, appearing less often than dulling but more disruptive when present.

- Early signs: Buyers notice vibration, chatter, or uneven cuts on the first cut.

- Cause: Reports point to inconsistent shank tolerance and occasional poor machining.

- Impact: Wobble increases tearout and requires rework, costing extra time and material.

Will the case and set organization save time in the shop?

- Immediate issue: The aluminum carry case often lacks clear labeling and secure slots for every bit.

- Frequency: This organizational flaw is commonly reported and affects first-day setup and long-term storage.

- Hidden requirement: Buyers frequently need to add foam or aftermarket organizers to prevent contact between bits.

- Impact: Poor protection increases the chance of edge damage during transit or storage.

- Attempts to fix: Many users rehouse bits into custom foam or magnetic racks immediately.

- Category contrast: Typical mid-range kits include molded slots or better labeling, reducing immediate rework.

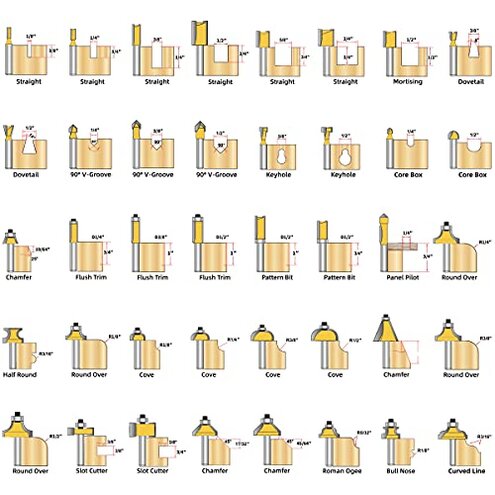

Why do some bits in the set perform well while others fail?

- Consistency problem: Buyers report mixed quality inside the same set, with a few sharp bits and several underperformers.

- Scope signal: This variability appears across multiple feedback sources and not just isolated examples.

- When it matters: Inconsistent bits become obvious during multi-bit jobs or when replacing a worn cutter mid-project.

- Frustration level: This is more frustrating than a single bad bit because it affects tool selection and workflow planning.

- Attempts to mitigate: Buyers separate and test each bit before use or buy backups for critical profiles.

- Repairability: Some users can resharpen, but that adds time and tools most buyers did not plan for.

- Category contrast: Mid-range competitors tend to have tighter quality control, resulting in fewer variances across a set.

Illustrative excerpts (not real quotes)

- "Edges dulled after two cabinet doors, needed resharpening." — reflects a primary pattern.

- "One bit wobbled so much I stopped after the first cut." — reflects a secondary pattern.

- "Case slots were loose and bits banged together in transit." — reflects a secondary pattern.

- "Half the set was usable, half needed rework before use." — reflects an edge-case pattern.

Who should avoid this

- Hardwood pros: Anyone doing frequent hardwood work should avoid this set due to faster-than-normal carbide wear.

- Precision finishers: Those needing consistently sharp edges for fine joinery will find the variability unacceptable.

- Busy shops: High-volume users who cannot afford extra time for testing, resharpening, or reordering replacements should look elsewhere.

Who this is actually good for

- Hobbyists on a budget: DIYers doing light, occasional routing may tolerate shorter life for the lower upfront cost.

- Experimenters: Makers who expect to test profiles or create templates and plan to resharpen can accept variability.

- Backup sets: Shops wanting inexpensive backup cutters for non-critical spacing or template work may find it acceptable.

Expectation vs reality

- Expectation: Reasonable for this category is stable cutting life across the set.

- Reality: The set often shows inconsistent sharpness and earlier edge failure than that reasonable baseline.

- Expectation: Router bits should seat cleanly with minimal runout for safe, smooth cuts.

- Reality: Some users see noticeable wobble on first use, which is worse than category norms.

Safer alternatives

- Buy tested brands: Choose brands known for tighter shank tolerance to reduce runout and vibration.

- Prioritize carbide quality: Look for sellers that specify carbide grade or offer longer lifespan claims to avoid early dulling.

- Check case design: Pick kits with molded foam or individual sleeves to prevent edge contact in storage.

- Plan for sharpening: If buying this kit, budget a resharpening option or stone to maintain edge life.

The bottom line

Main regret: The most common trigger is quicker-than-expected carbide dulling and inconsistent bit quality across the set.

Verdict: For woodworkers who need consistent, long-lasting cutters, this set presents a higher-than-normal risk and is often worth avoiding.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.