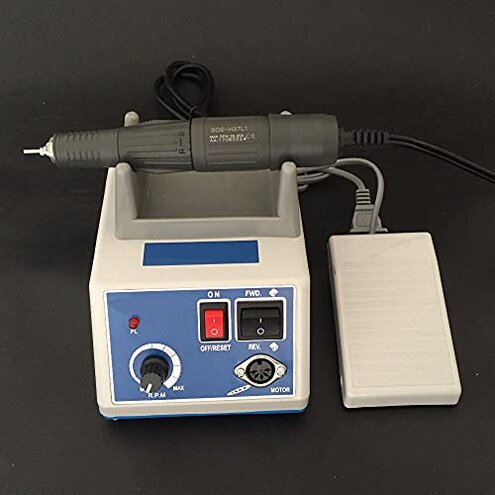

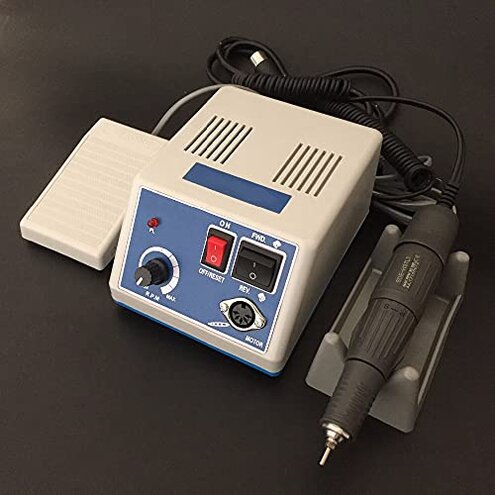

Product evaluated: Marathon -III MICROMOTOR Lab Jewelry Micromotor Micro Motor Hand Kit Fit Marathon

Related Videos For You

Dental Handpiece Motors and Attachments and Placed on the Dental Unit (Part 1)

Dremel/Rotary Tool 101: Complete Beginner Guide

Dozens of buyer comments and demonstrations were summarized for this report. The dataset spans Jan 2020–Dec 2025 and combines written reviews and short video demonstrations. Most feedback came from written reviews, with supporting video clips showing real-use problems.

| Outcome | Marathon unit | Typical mid-range tool |

|---|---|---|

| Durability | Shorter lifespan reported under regular use compared to peers. | Moderate lifespan with routine maintenance expected. |

| Noise & heat | Higher noise and heat buildup during sustained sessions. | Quieter operation in comparable mid-range models. |

| Power consistency | Higher-than-normal risk of power sag or stalling during long jobs. | More stable torque for continuous use in the category baseline. |

| Ease of setup | Simple hardware but missing steps noted in guides. | Smoother out-of-box setup with clearer documentation. |

| Regret trigger | Power loss mid-task leading to ruined work. | Intermittent annoyances less likely to stop a job. |

Top failures

Why does the motor lose power during longer jobs?

Regret moment comes when the tool slows or stalls mid-task, which often ruins delicate workpieces.

Pattern appears repeatedly across buyer reports and video demos, especially in sessions longer than 10–20 minutes.

Category contrast shows this is worse than normal because similar mid-range tools usually maintain steady torque during comparable jobs.

Is the unit prone to overheating and loud operation?

- Early signs: fans and handle feel hot after short use.

- Frequency tier: commonly reported rather than isolated.

- Cause: appears during continuous sanding/grinding.

- Impact: heat speeds wear and raises noise, interrupting sessions.

- Fix attempts: buyers used breaks and external cooling with limited success.

Why do controls and the foot switch feel unreliable?

- Control issue: power toggles or inconsistent response reported after setup.

- When it shows up: during start-up and when pressing the foot switch repeatedly.

- Scope: persistent for many users, not just a few early buyers.

- Cause guess: loose wiring or weak switch components under repeated presses.

- Impact: stops work unexpectedly and can damage delicate pieces.

- Fixability: some buyers re-soldered or replaced switches to restore reliability.

Will the build and maintenance needs surprise you?

- Hidden requirement: regular maintenance is needed to keep torque steady.

- Early signs: increasing vibration after weeks of use.

- Frequency tier: a primary concern for frequent users and labs.

- Cause: wear on internal parts from heavy-duty sessions.

- Impact: incurs extra downtime and cost for replacements or repairs.

- Attempts: users report temporary fixes but repeat interventions are common.

- Category contrast: more upkeep than most mid-range alternatives, so long-term cost rises.

Illustrative excerpts (not real quotes)

"Motor slowed halfway through a bezel setting." — reflects a primary pattern.

"Foot switch cut out after a month of use." — reflects a secondary pattern.

"Handle got very hot during a long polishing run." — reflects a secondary pattern.

Who should avoid this

- Continuous users: avoid if you need reliable power for long sessions because power sag is common.

- High-precision shops: avoid if you cannot tolerate mid-task stalls that ruin fine work.

- Low-maintenance buyers: avoid if you don’t want frequent repairs or switch replacements.

Who this is actually good for

- Occasional hobbyists: okay if you run short sessions and can tolerate noise and heat.

- Budget starters: fine for users who accept extra maintenance to save on upfront cost.

- DIY fixers: suitable if you can replace switches or do simple wiring to improve reliability.

Expectation vs reality

- Expectation: reasonable for this category to need some upkeep.

- Reality: this unit requires more frequent maintenance than typical mid-range tools, creating extra cost and downtime.

- Expectation: a foot switch should be a simple, reliable control.

- Reality: users report switch failures that interrupt work and need replacement.

Safer alternatives

- Seek higher torque ratings: choose units advertised for continuous-duty to avoid mid-job power loss.

- Prefer replaceable switches: pick models with known serviceable foot switches to reduce downtime.

- Check cooling design: prefer tools with documented cooling or larger housings to reduce heat buildup.

- Read maintenance notes: choose tools with clear parts and service guides to lower repair friction.

The bottom line

Main regret: unexpected power sag and reliability issues during longer sessions are the central complaint.

Why it matters: these failures exceed normal category risk because they stop jobs and raise repair costs.

Verdict: avoid this unit if you need steady, long-session performance; consider it only for short, occasional use or if you can perform repairs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.