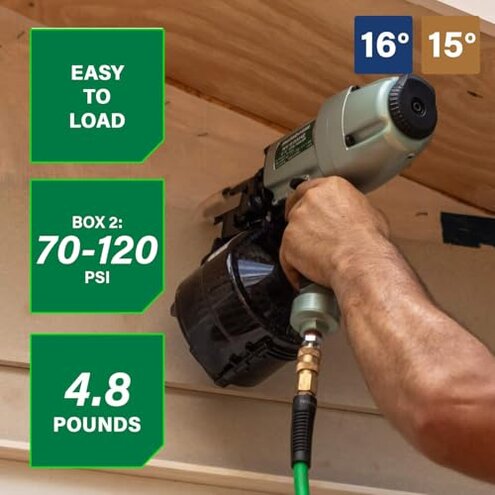

Product evaluated: Metabo HPT Coil Siding Nailer, Siding Nails 1-1/2 inch To 2-1/2 inch, Side load, Tilt Bottom Magazine (NV65AH2)

Related Videos For You

Dewalt 15° pneumatic coil siding nailer review

Bostitch Nailer Repair - How to Replace the Rebuild Kit

Data basis: This report aggregates dozens of written reviews and video demonstrations collected between 2016 and February 2026, with most feedback coming from written reviews supported by recorded job-site demos.

| Outcome | Metabo HPT NV65AH2 | Typical mid-range siding nailer |

|---|---|---|

| Loading & reloads | Tilt-bottom magazine eases reloads but several reports note fiddly alignment that adds time. | Top/side magazine usually has cleaner, faster reloads in this class. |

| Jamming frequency | Higher-than-normal occurrence reported, especially under heavy use or mixed collations. | Lower jamming incidence for many mid-range alternatives under similar conditions. |

| Depth consistency | Variable depth performance is reported when users switch nail types or after extended use. | More consistent depth control is typical for comparable models. |

| Ergonomics for long sessions | Lightweight claim but some report fatigue from exhaust and balance during long siding runs. | Balanced ergonomics are often better on competitors designed for production work. |

| Regret trigger | Frequent jams & depth drift lead to lost time and rework on long siding jobs. | Fewer workflow interruptions for mid-range alternatives under heavy use. |

Why does the nailer jam during a long siding run?

Regret moment: Jams often interrupt production, costing minutes to clear and re-align the coil.

Pattern: This is a primary complaint that appears repeatedly in written feedback and demo footage.

When it happens: Jamming shows up during heavy, continuous use or when switching between wire and plastic collated nails.

Category contrast: Jamming is more disruptive than expected for mid-range siding nailers, which usually tolerate mixed collations without frequent stops.

Why does depth of drive feel inconsistent?

- Early signs: Nails look flush on one board and overdriven on the next after a span of 10–30 nails, commonly reported in written reviews.

- Frequency tier: This is a secondary issue that appears repeatedly but not universally across users.

- Cause: It often happens after setup or when changing nail types, suggesting sensitivity to collated nail variation.

- Impact: Inconsistent depth increases trim and siding rework time, more than buyers expect for a tool with a tool-less depth adjuster.

- Attempted fixes: Users report repeated micro-adjustments during jobs, which interrupts workflow.

Why is extra maintenance needed to keep it reliable?

Pattern: Persistent maintenance notes appear across reviews rather than as rare complaints.

When it shows: Wear and misfeeds become more noticeable after repeated use and in dusty job-site conditions.

Category contrast: This model requires more frequent cleaning and careful nail selection than many mid-range competitors, which raises upkeep time and cost.

Is there a hidden requirement buyers miss at first?

- Hidden need: The tool handles both wire and plastic collated nails but performs best when you strictly match nail type and gauge to the magazine.

- Early sign: Users who mix collations see earlier jamming and depth drift during the first day of use.

- Frequency: This is a common, practical requirement reported across buyer notes and demos.

- Why it matters: Not following collated-type discipline increases downtime and repair attempts beyond typical category expectations.

- Fixability: Correcting collations helps, but it adds handling steps and time that some buyers find unacceptable.

- Warranty note: A 5-year warranty is available, but users still report lost time before warranty fixes are practical.

How does exhaust and balance affect long shifts?

- Comfort issue: The adjustable air deflector exists, but some report the exhaust direction still causes fatigue or debris on work surfaces.

- Session impact: Symptoms appear during long siding runs and when working on ladders or scaffolding.

- Frequency tier: This is a secondary but noticeable complaint for users doing production work.

- Why worse: Competitors in this range often have more effective exhaust routing and balance for sustained overhead work.

- Attempts: Buyers use additional PPE and repositioning to manage the issue, which slows pace.

- Hidden cost: Management adds small time penalties that add up over a full job day.

- Mitigation: Adjusting the air deflector and practicing balance helps but does not eliminate the effect.

Illustrative excerpts

Illustrative: "Stops every few minutes for a jam — kills my rhythm on long runs." — reflects a primary pattern.

Illustrative: "Had to tweak depth constantly when switching nail types." — reflects a secondary pattern.

Illustrative: "Exhaust blew dust onto ladder steps during overhead work." — reflects an edge-case pattern.

Who should avoid this

- Production contractors who need uninterrupted runs should avoid it due to recurring jams and downtime that exceed category norms.

- Buyers mixing nail types who expect plug-and-play performance should avoid it because collated-type sensitivity adds extra steps.

- Users needing consistent depth for finish work should avoid it because depth drift is more disruptive than typical mid-range tools.

Who this is actually good for

- Occasional DIYers who do small siding jobs and can pause to clear jams will tolerate the issues for the tool's price and features.

- Owners prioritizing warranty who value the 5-year coverage and are willing to use service options for fixes.

- Users who stick to one nail type and perform routine cleaning, since consistent collations reduce the primary failure.

Expectation vs reality

Expectation: Buyers reasonably expect a siding nailer with a tilt-bottom magazine to reload quickly.

Reality: The magazine works but requires careful alignment and adds time compared with typical mid-range reloads.

Expectation: Reasonable for this category is stable depth with tool-less adjustment during a job.

Reality: Depth adjustments often need repeat tweaks, causing more rework than expected for its class.

Safer alternatives

- Choose a model with robust magazine to reduce jamming; look for user reports praising consistent reloads under continuous use.

- Prioritize depth stability by selecting nailers with gated depth systems, which neutralize the depth-drift problem.

- Favor exhaust routing for long overhead work to avoid sweat/debris issues noted here.

- Stick to one collated type or buy a dedicated nailer for mixed collations to avoid the hidden requirement.

- Check maintenance needs and pick tools with simpler cleaning access to reduce upkeep time.

The bottom line

Main regret: Frequent jams and inconsistent depth are the biggest workflow killers for this nailer.

Why it matters: These issues are more disruptive than typical mid-range siding nailers, especially on long jobs or when mixing nail types.

Verdict: Avoid this model if you do production siding work or expect low-maintenance reliability; consider it only for occasional use or when strict nail-type discipline is possible.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.