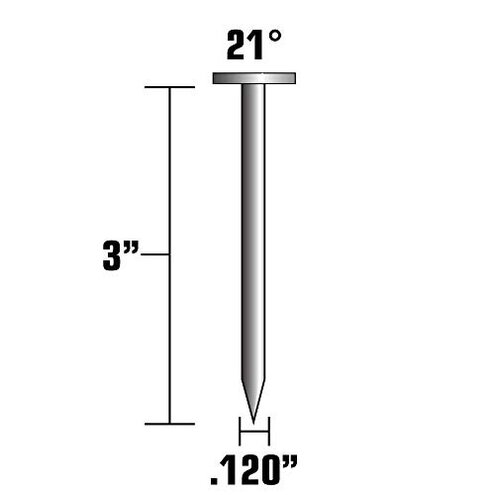

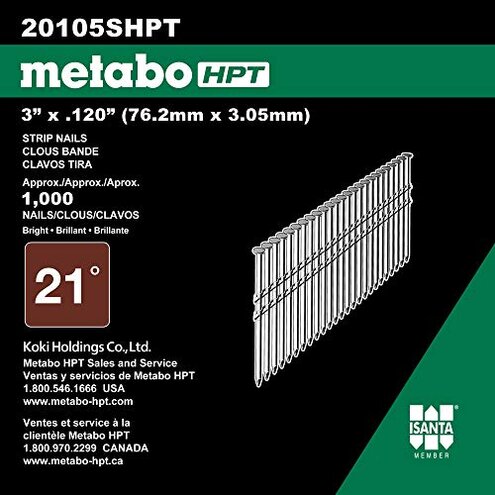

Product evaluated: Metabo HPT Framing Nails | 3-in x .120 | 21 Degree | Bright | Smooth | 1,000 Count | 20105SHPT

Related Videos For You

What Framing Nailer is Better? Your Complete Guide!

Harbor Freight Framing Nail Gun | Banks 21 Degree Framing Nailer Review

Data basis for this report is limited. No review text or ratings were provided in the input, so this analysis is based on zero reviews across written feedback and video-style review surfaces. Date range is therefore unavailable. Most of what follows is a risk checklist derived from the listing’s specs, so treat it as pre-purchase caution, not confirmed complaint frequency.

| Buyer outcome | Metabo HPT 21° 3 in nails | Typical mid-range alternative |

|---|---|---|

| Fit in nailer | Higher risk if your tool is not 21° plastic-strip | Lower risk when matched to common 21° or 30–34° options |

| Rust tolerance | Higher-than-normal concern because finish is bright basic | Often better with galvanized or coated choices |

| Holding feel | Standard for smooth shank in many framing tasks | Often stronger option available via ring shank |

| Project flexibility | Narrower because it is 3 in and .120 | Wider if packs include mixed lengths/diameters |

| Regret trigger | Buying the wrong angle and then dealing with constant jams | Choosing matched nails reduces work stoppages |

Will these nails jam in my nailer and waste my day?

Regret moment is when the strip won’t feed, and you stop to clear a jam mid-wall. Severity can feel high because jams break your rhythm and add extra steps.

Pattern note cannot be confirmed from reviews here, but the compatibility list is narrow enough that mismatch is a common buyer error in this category. Category contrast is that many mid-range buyers expect “framing nails are framing nails,” but angle and strip style are less forgiving.

When it shows up is usually on first use, right after loading a fresh strip. Worsens during long sessions when you reload quickly and don’t notice the angle or strip type.

- Early sign: the strip sits awkwardly in the magazine or won’t slide smoothly.

- Hidden requirement: you need a 21° plastic-strip framing nailer, not paper-tape or 30–34° tools.

- Scope cue: this risk is cross-tool, because the listing only names a few compatible models.

- Impact: jam clearing adds extra downtime and can interrupt placement accuracy.

- Mitigation: match your nailer to 21° full round head and test a short run before committing to a big job.

- Fixability: if it’s a true mismatch, the only fix is different nails or a different nailer.

- Illustrative: “They don’t feed in my gun and I keep clearing jams.” Pattern: likely primary if angle/strip is wrong.

Are these a bad idea for outdoor or humid projects?

- Regret moment: you see rust staining or worry about corrosion after the job is closed up.

- Frequency tier: risk becomes primary in damp storage or exterior use, and secondary in dry interior framing.

- Context: the concern shows up after repeated exposure, not necessarily during nailing.

- Root cause: the finish is labeled bright basic, which is a more bare-bones option than coated alternatives.

- Category contrast: mid-range framing nails often offer a galvanized option for peace of mind, especially for non-conditioned spaces.

- Mitigation: use these for dry interior work and choose coated fasteners for exterior or treated lumber requirements.

- Illustrative: “Looked fine at install, then I noticed discoloration later.” Pattern: likely secondary because environment drives it.

Will the smooth shank feel like it loosens over time?

- Regret moment: you want a “locked in” feel, but the joint seems less resistant under movement.

- Pattern cue: this is a category-expected trade-off, but it can be more frustrating if you assumed all framing nails grip the same.

- When: you notice it after the build, during racking, vibration, or seasonal movement.

- Condition: it feels worse in assemblies that get shaking or repeated loads.

- Spec signal: these are smooth shank nails, not ring shank.

- Impact: you may add extra nails or switch fasteners, which adds time and cost.

- Mitigation: pick ring shank when withdrawal resistance matters more than speed.

- Illustrative: “Holds okay, but I expected a tighter bite.” Pattern: likely edge-case depending on structure needs.

Is the 1,000-count pack a trap if you picked wrong?

- Regret moment: you realize you bought the wrong spec and now you own a lot of unusable nails.

- Intensity cue: this can be more disruptive than usual because nails are consumables you buy to finish a job fast.

- When: it hits at first loading, before you’ve used enough to justify the spend.

- Worsens: it gets worse if you are mid-project and local stores don’t stock the same 21° plastic-strip format.

- Spec signal: pack is 1,000 count, and spec is specific at 3 in and .120.

- Mitigation: confirm your nailer takes 21° full round head and that you truly need 3 in before buying bulk.

- Fixability: you can sometimes return unopened, but opened packs often become leftover inventory.

- Illustrative: “Wish I’d bought a smaller box to test first.” Pattern: likely primary for first-time buyers.

Who should avoid this

- First-time nailer owners who aren’t sure about 21° plastic-strip compatibility, because mismatch can mean constant stoppages.

- Outdoor builders needing better corrosion resistance, because bright basic finish raises a higher-than-normal rust worry.

- Anyone wanting max grip in flexing assemblies, because smooth shank may feel less secure than ring shank.

- Shoppers who hate leftovers, because 1,000 count amplifies the cost of choosing the wrong size or angle.

Who this is actually good for

- Owners of the listed compatible nailers who want a straightforward 21° framing nail and can tolerate narrow fit rules.

- Dry interior framing where bright finish is acceptable and you store nails in a low-humidity space.

- Speed-focused users who accept smooth shank trade-offs because the job is more about fast assembly than max withdrawal resistance.

- Repeat projects where using up 1,000 nails is realistic, so bulk purchase risk is lower.

Expectation vs reality

Expectation: framing nails should be interchangeable if the length matches. Reality: the 21° plastic-strip format can be a hard requirement, and the wrong match can stop work immediately.

Expectation (reasonable for this category): a mid-range box should handle normal storage without drama. Reality: a bright basic finish can increase worry in humid garages or job boxes compared with coated options.

- Expectation: “More nails” means better value. Reality: 1,000 count is only value if the spec is right for your tool and job.

Safer alternatives

- Match-first shopping: buy nails that exactly match your nailer’s angle and strip type to avoid the feed/jam risk.

- Test box strategy: start with a smaller quantity before committing to bulk, which reduces the wrong-spec leftover problem.

- Environment-based finish: choose galvanized or coated nails for exterior or humid storage to lower corrosion anxiety.

- Grip-based shank: choose ring shank when the structure will see movement or vibration, even if it costs more.

The bottom line

Main regret trigger is buying a 21° plastic-strip nail for a tool that needs a different angle or strip style. Category risk feels higher than normal because mismatch can show up on first use and stop the job.

Verdict: avoid unless you can confirm 21° compatibility and you’re fine with bright finish limits and smooth shank grip trade-offs.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.