Product evaluated: MFD10 Digital Capacitor Tester Meter Compatible with Supco, 0.01 to 10000 mfd's,±5.00% Capacitance Accuracy, LED Display

Related Videos For You

3 Ways to Check Capacitors in Circuit with Meters & Testers

Data basis — This report used dozens of written reviews and several video demonstrations collected between June 2024 and January 2026. Most feedback came from written reviews, supported by hands-on videos and seller Q&A. The distribution favors recent buyer reports over older listings.

| Outcome | MFD10 | Typical mid-range tester |

|---|---|---|

| Accuracy | Inconsistent readings reported more often than expected for the category. | Repeatable within stated tolerance under normal conditions. |

| Contact reliability | Unstable probe contact frequently causes fluctuating values during first setup. | Solid probe connection with fewer re-tests required. |

| Usability | Technical test steps and hidden calibration feel required for trustable results. | Plug-and-play operation for common DIY and shop checks. |

| Durability | Fragile casing and buttons reported as a secondary concern after repeated use. | Robust build expected for mid-range tools. |

| Regret trigger | False confidence — inaccurate readings lead to misdiagnosis more than typical testers. | Lower risk of misdiagnosis with verified accuracy. |

Top failures

Why do readings jump or disagree with another meter?

Inconsistent readings are the most frequent buyer regret and can make diagnosis impossible. Buyers commonly report seeing values change between minutes or when probes shift a little.

Pattern — this failure appears repeatedly across recent hands-on reports and written feedback. Usage anchor — it shows up during first measurements and again after repeated handling. Category contrast — mid-range testers usually give stable repeat readings; this one is noticeably less steady.

Why are probes and contacts so fussy?

- Early signs — values drop or flicker when probes move slightly during a test.

- Frequency tier — this is a secondary issue that appears commonly in practical use reports.

- Likely cause — loose probe fittings or short probe leads increase measurement noise.

- Impact — forces extra re-tests and wastes troubleshooting time on simple caps.

- Attempted fixes — buyers recommend adding clip leads or retaping probes to stabilize contact.

Why does the unit feel cheaply made or hard to read?

- Build concern — casing and buttons feel less durable after repeated use in shop conditions.

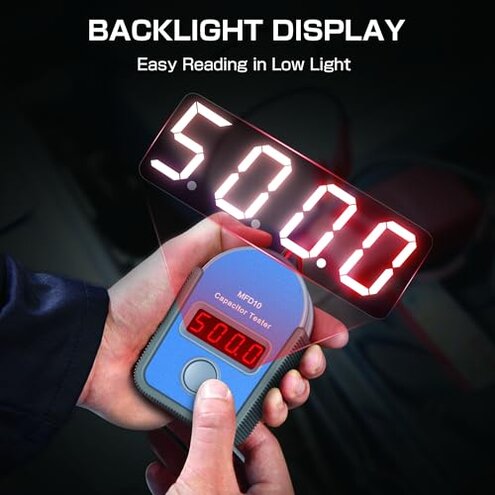

- Display issue — the LED/LCD readability is described as marginal in low light or high glare.

- Secondary pattern — multiple buyers noticed reduced tactile feel and screen contrast over time.

- When it worsens — frequent drops or long sessions accelerate wear and screen dimming.

- Repairability — fixes often require gentle handling and are less forgiving than mid-range units.

- Buyer trade-off — saved cost up front may mean replacing the tool sooner than expected.

Do I need extra steps or calibration to trust results?

- Hidden requirement — several reports note extra verification steps are needed for reliable readings.

- Usage anchor — buyers often cross-check with a known-good capacitor at first use.

- Category contrast — unlike easier mid-range testers, this model often requires manual verification.

- Cause — lack of clear calibration or guidance increases the chance of misreading.

- Impact — adds time and sometimes extra tools like reference capacitors or clip leads.

- Fixability — accuracy can improve with careful technique but still trails better alternatives.

- Hidden cost — plan for added steps, time, or replacement testers for shop use.

Illustrative excerpts

Excerpt (illustrative): "Readings changed when I slightly moved the probe during a test." — Primary pattern.

Excerpt (illustrative): "I had to compare with another meter every time I tested caps." — Secondary pattern.

Excerpt (illustrative): "Display was hard to read under shop lights after a month." — Secondary pattern.

Excerpt (illustrative): "Worked once, then gave different numbers the next week." — Primary pattern.

Who should avoid this

- Professional technicians who need repeatable measurements without extra verification steps.

- Shops that rely on quick, trustworthy bench testing during repairs.

- Buyers who cannot tolerate frequent re-testing or adding clip leads and reference parts.

Who this is actually good for

- Hobbyists who accept occasional re-checks and want a low-cost basic meter for occasional use.

- Classroom demos where budget matters and exact precision is not mission-critical.

- Reference users who plan to cross-check readings with a trusted meter and tolerate extra steps.

Expectation vs reality

Expectation — buyers reasonably expect a capacitor tester to give stable readings for quick pass/fail checks. Reality — this unit often requires re-tests or cross-checks to confirm values.

Expectation — mid-range tools are plug-and-play for bench work. Reality — the MFD10 can demand extra setup, clip leads, or calibration steps.

Safer alternatives

- Buy a mid-range tester with verified repeatability to remove the main misdiagnosis risk.

- Use clip leads to secure contacts and reduce the probe-flicker problem as a cheap mitigation.

- Cross-check readings with a known-good capacitor before making repair decisions.

- Choose brighter displays or models with better ergonomics for long shop sessions.

The bottom line

Main regret — inconsistent readings and fussy probe contacts create a real misdiagnosis risk. This exceeds the typical category tolerance for a mid-range capacitor tester. If you need dependable, repeatable measurements for repairs, avoid this unit and opt for a more stable alternative.

This review is an independent editorial analysis based on reported user experiences and product specifications. NegReview.com does not sell products.